– 19 –

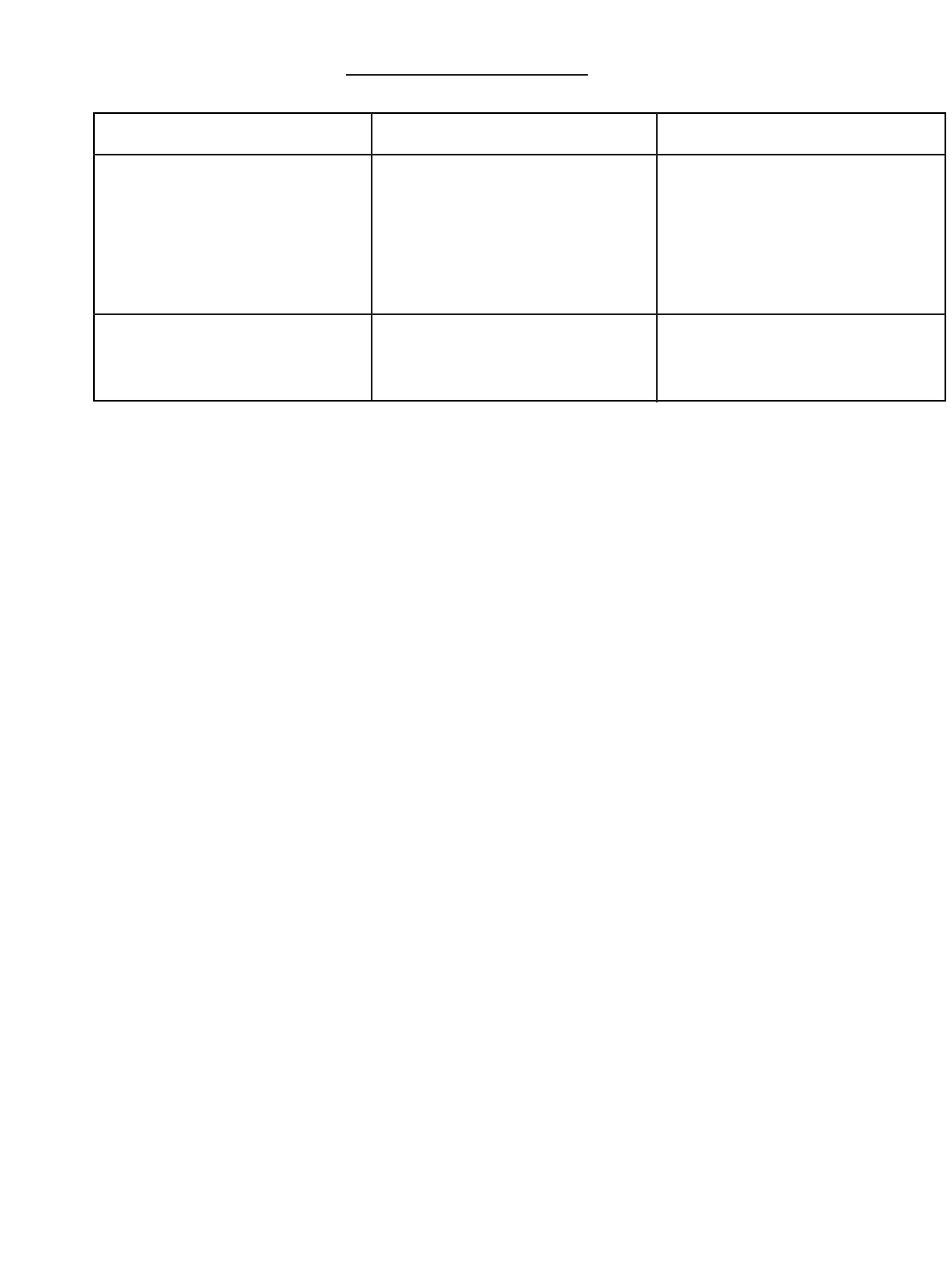

TROUBLE

D. Welding current too great or

too small compared to

indication on the dial.

E. Arc continuously pops out.

CAUSE

1. Exciter output low causing low

output compared to dial

indication.

2. Operating speed too low or high.

1. “Current Range Selector” switch

may be set at an intermediate

position.

WHATTODO

1. Check exciter field circuit.

2. Adjust speed screw on governor

for 1800 RPM operating speed.

1. Set the switch at the center of

the current range desired.

TROUBLESHOOTING

(Continued)

(1)

FLASHING THE FIELDS

AC Auxiliary Power:

1. Stop the engine welder and remove the cover from the exciter.

2. Turn the “Fine Adjustment Control” (rheostat) to “100” on the dial.

3. Using a 12 volt automotive battery, connect its negative terminal to the negative brushholder. The negative

brushholder is the one nearest to the rotor lamination. See the wiring diagram. With the engine NOT running,

touch the positive battery terminal to the positive brushholder. Remove the battery from the circuit.

4. Replace the exciter cover. Start the welder and the generator voltage should build up.