– 12 –

Battery Charging

The 350-SA is equipped with a wet charged battery.

The charging current is automatically regulated when

the battery is low (after starting the engine) to a trickle

current when the battery is fully charged.

When replacing, jumping or otherwise connecting the

battery to the battery cables, the proper polarity must

be observed. The system is NEGATIVE GROUND.

PRE-OPERATION SERVICE

READ the engine operating and maintenance

instructions supplied with this machine.

------------------------------------------------------------

Oil

This unit is supplied from the factory with the engine

crankcase filled with a high quality 10W30 oil. This oil

should be acceptable for most typical ambient

temperatures. Consult the engine operation manual

for specific engine manufacturer’s recommendations.

Upon receipt of the welder, check the engine dipstick

to be sure the oil is at the “full” mark. DO NOT

OVERFILL.

Fuel

Fill the fuel tank with the grade of fuel recommended

in the Engine Operator’s Manual. Make sure the fuel

valve on the sediment bowl is in the open position.

Cooling System

The cooling system has been filled at the factory with

a 50-50 mixture of ethylene glycol antifreeze and

water. Check the radiator level and add a 50-50

solution as needed. (See engine manual or antifreeze

container from alternate antifreeze recommendation.)

Fuel

can cause fire or explosion.

-

• Stop engine while fueling.

• Do not smoke when fueling.

• Do not overfill tank.

• Keep sparks and flame away from tank.

• Wipe up spilled fuel and allow fumes to clear

before starting engine.

------------------------------------------------------------------------

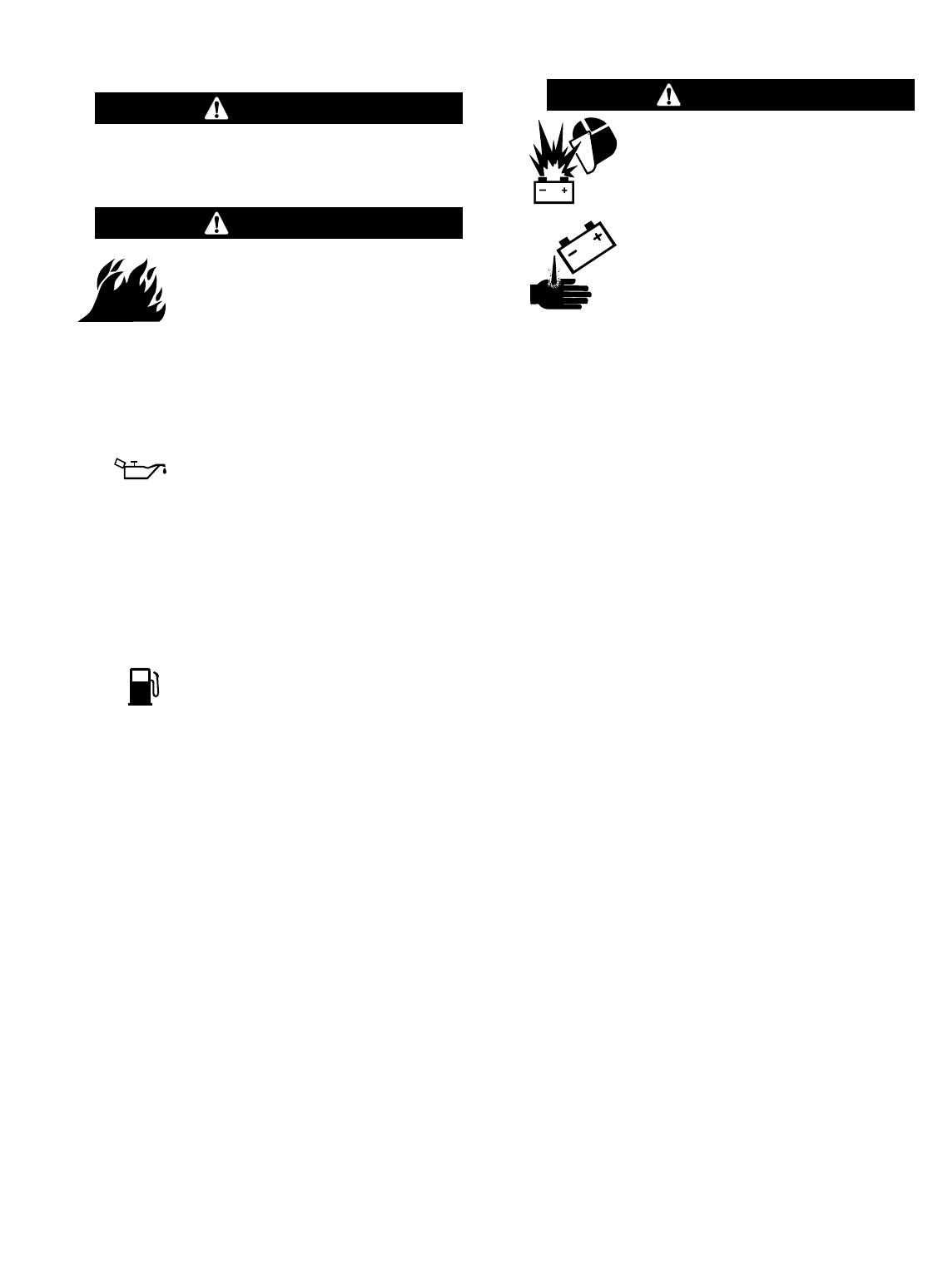

WARNING

CAUTION

GASES FROM BATTERY can explode.

• Keep sparks, flame and cigarettes

away.

BATTERY ACID can burn eyes and

skin.

• Wear gloves and eye protection and

be careful when boosting, charging or

working near battery.

To prevent EXPLOSION when:

a) Installing a new battery - disconnect the

negative cable from the old battery first and

connect the negative cable to the new battery

last.

b) Connecting a battery charger - remove the

battery from the welder by disconnecting the

negative cable first, then the positive cable and

battery clamp. When reinstalling, connect the

negative cable last.

c) Using a booster - connect the positive lead to

the battery first, then connect the negative lead to

the ground lead on the base.

To prevent ELECTRICAL DAMAGE when:

a) Installing a new battery.

b) Using a booster.

Use correct polarity - Negative Ground.

To prevent BATTERY DISCHARGE, if you have an

ignition switch, turn it off when engine is not

running.

• To prevent BATTERY BUCKLING, tighten nuts on

battery clamp until snug.

------------------------------------------------------------------------

WARNING