B-1

INSTALLATION

B-1

INSTALLATION

HAVE QUALIFIED PERSONNEL DO THE INSTAL-

LATION WORK. TURN THE ENGINE OFF BEFORE

WORKING INSIDE THE MACHINE. IN SOME

CASES IT MAY BE NECESSARY TO REMOVE

SAFETY GUARDS TO PERFORM REQUIRED

INSTALLATION. REMOVE GUARDS ONLY WHEN

NECESSARY AND REPLACE THEM WHEN THE

INSTALLATION REQUIRING THEIR REMOVAL IS

COMPLETE. ALWAYS USE THE GREATEST CARE

WHEN WORKING NEAR MOVING PARTS.

LN-15, LN-22, LN-25 Connection — Instructions cov-

ered under “Operation”.

LN-7 Connection — An LN-7 can be connected to SA-

250, SAE-300, SAE-350, SAE-400 and SAE-400

WELD’N AIR engine welders that have AC auxiliary

power by using a K240 Contactor Kit. Connect the con-

tactor kit to the engine welder and LN-7 per S17525 or

S15416 connection diagram that is sent with the K240

Contactor Kit. The engine welder 115 volt receptacle

will supply the AC power that is needed. Place the

welder idler control in the high position before welding.

When the LN-7 is connected to an SA-250 or SAE-350,

it will not run at low idle when the idle control is in the

automatic position. The plug connecting the K240

Contactor Kit to the SA-250 or SAE-350 auxiliary

power receptacle must be disconnected to allow the

engine to run at low idle.

ANY SPEED UP OF THE ENGINE RPM BY

CHANGING THE GOVERNOR SETTING OR OVER-

RIDING THE THROTTLE LINKAGE WILL CAUSE

AN INCREASE IN THE AC AUXILIARY VOLTAGE.

IF THIS VOLTAGE GOES ABOVE 140 VOLTS, THE

LN-7 CONTROL CIRCUIT AND/OR THE CV

ADAPTER CIRCUIT WILL BE DAMAGED! THE

ENGINE GOVERNOR SETTING IS PRESET AT THE

FACTORY — DO NOT ADJUST ABOVE RPM

SPECIFICATIONS LISTED IN ENGINE WELDER

OPERATING MANUAL.

The following tools and materials are recommended for

attaching the CV Adapter to an engine welder:

1. Measuring tape, hammer, center punch and electric

drill with 13/32" drill bit. This is only needed for SA-

250 engine welders that do not have mounting

holes in fuel tank rail.

2. Set of socket wrenches.

3. 11/32" wrench and 3/8" nut driver or pliers.

4. 1/2" open end wrench and 9/16" wrench.

5. Screwdriver.

6. Electrical insulating tape.

K384 CV ADAPTER TO SA-200 ENGINE

WELDER

NOTE: BEFORE INSTALLING CV ADAPTER, START

ENGINE WELDER AND USE A DC VOLTMETER TO

CHECK THE POLARITY OF THE RED AND BLACK

LEADS CONNECTED TO THE AUXILIARY POWER

RECEPTACLE. THE RED LEAD SHOULD BE NEGA-

TIVE AND THE BLACK LEAD SHOULD BE POSI-

TIVE. IF THE POLARITY IS NOT CORRECT, REFER

TO ENGINE WELDER OPERATING MANUAL FOR

INSTRUCTIONS TO FLASH THE EXCITER TO

OBTAIN THE CORRECT POLARITY.

• TURN THE ENGINE OFF WHILE INSTALLING

THIS ACCESSORY.

• KEEP HANDS, HAIR, CLOTHING AND TOOLS

AWAY FROM MOVING PARTS WHEN STARTING

OR OPERATING ENGINE.

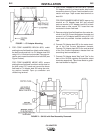

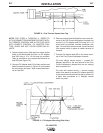

1. Remove roof assembly and bracket cover (cover

on top and at rear of generator). (See Figure 2.)

Also, remove the two gas tank support mounting

bolts on the side opposite the output studs.

2. Mount CV Adapter (nameplate should have an

“SA” above the code number) to the gas tank sup-

port holes. Use one 3/8" bolt with hardware

removed in Step 1 and one stud on Adapter. One

3/8" bolt will not be used as a 3/8" stud from the

Adapter case replaces it. In mounting the unit, be

sure the fuel line and choke cable are not pinched.

(See Figure 1.)

NOTE: FOR STEPS 3 THROUGH 10, REFER TO

S17514 OR S17515 CONNECTION DIAGRAMS FOR

THE APPROPRIATE WELDER CODE NUMBER. CV

ADAPTER CONTROL LEADS ARE NOT COLOR

CODED ON ALL UNITS.

CV ADAPTER

WARNING

CAUTION

WARNING