VOLTAGE SENSING

The best arc performance occurs when the Power

Wave® s has accurate data about the arc conditions.

Depending upon the process, inductance within the

electrode and work lead cables can influence the volt-

age apparent at the contact tip. Voltage sense leads

improve the accuracy of the arc conditions and can

have a dramatic effect on performance.

If the voltage sensing is enabled but the sense

leads are missing or improperly connected,

extremely high welding outputs may occur.

Do not tightly bundle the work sense lead to the work

lead.

The ELECTRODE sense lead (67) is built into the

K1795 control cable. The WORK sense lead (21) con-

nects to the Power Wave® at the four-pin connector

located underneath the output stud cover.

Enable the voltage sense leads as follows:

TABLE 2

Process Electrode Voltage Work Voltage

Sensing 67 lead * Sensing 21 lead

GMAW 67 lead required 21 lead optional**

GMAW-P

67 lead required 21 lead optional**

FCAW 67 lead required 21 lead optional**

GTAW

Voltage sense at studs Voltage sense at studs

SAW 67 lead required 21 lead optional**

* The electrode voltage 67 sense lead is part of the

control cable to the wire feeder.

** For consistent weld quality, work voltage sensing is

recommended.

CAUTION

A-6

INSTALLATION

POWER WAVE® 655/R

A-6

When negative electrode polarity is required, such as

in some Innershield applications, reverse the output

connections at the power source (electrode cable to

the negative (-) stud, and work cable to the positive

(+) stud).

When operating with electrode polarity negative the

switch 7 must be set to ON on the Wire Feed Head

PC Board. The default setting of the switch is OFF to

represent positive electrode polarity.

Set the Negative Polarity switch on Wire Feed Head

PC board as follows:

ELECTRIC SHOCK can kill.

• Do not touch electrically live parts

or electrodes with your skin or wet

clothing.

• Insulate yourself from the work and

ground.

• Always wear dry insulating gloves.

------------------------------------------------------------------------

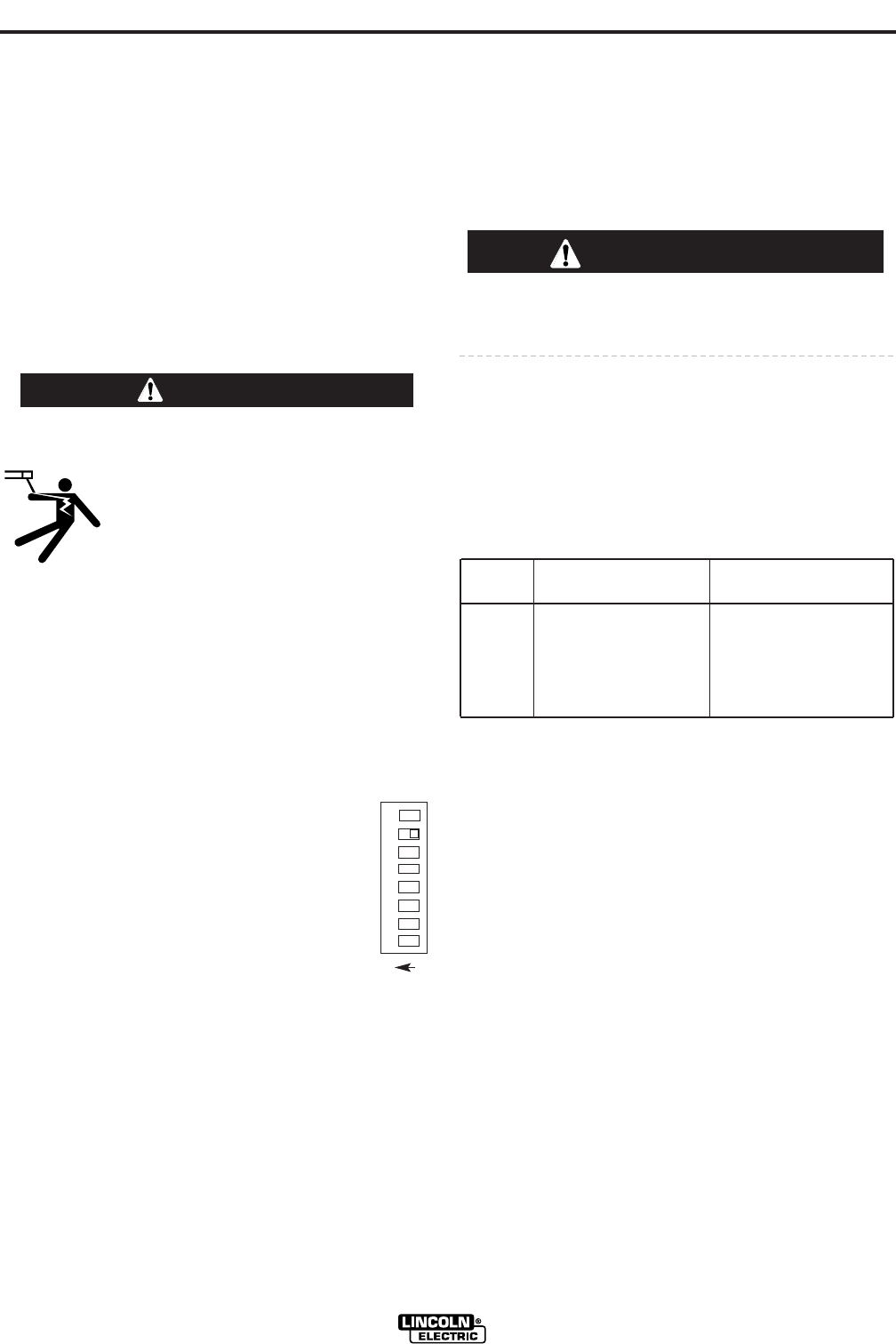

1. Turn off power to the power source at the discon-

nect switch.

2. Remove the front cover from the power source.

3. The wire feed head board is on the right side of the

power source. Locate the 8-position DIP switch and

look for switch 7 of the DIP switch.

4. Using a pencil or other small object, slide

the switch right to the OFF position for

positive electrode polarity. Conversely,

slide the switch left to the on position for

negative electrode polarity.

5. Replace the cover and screws. The PC

board will “read” the switch at power up,

and configure the work voltage sense lead appro-

priately.

WARNING

O

N

1 2 3 4 5 6 7 8