E-4

TROUBLESHOOTING

E-4

POWER WAVE® 655/R

Observe all Safety Guidelines detailed throughout this manual

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, con-

tact your local authorized Lincoln Electric Field Service Facility for technical assistance.

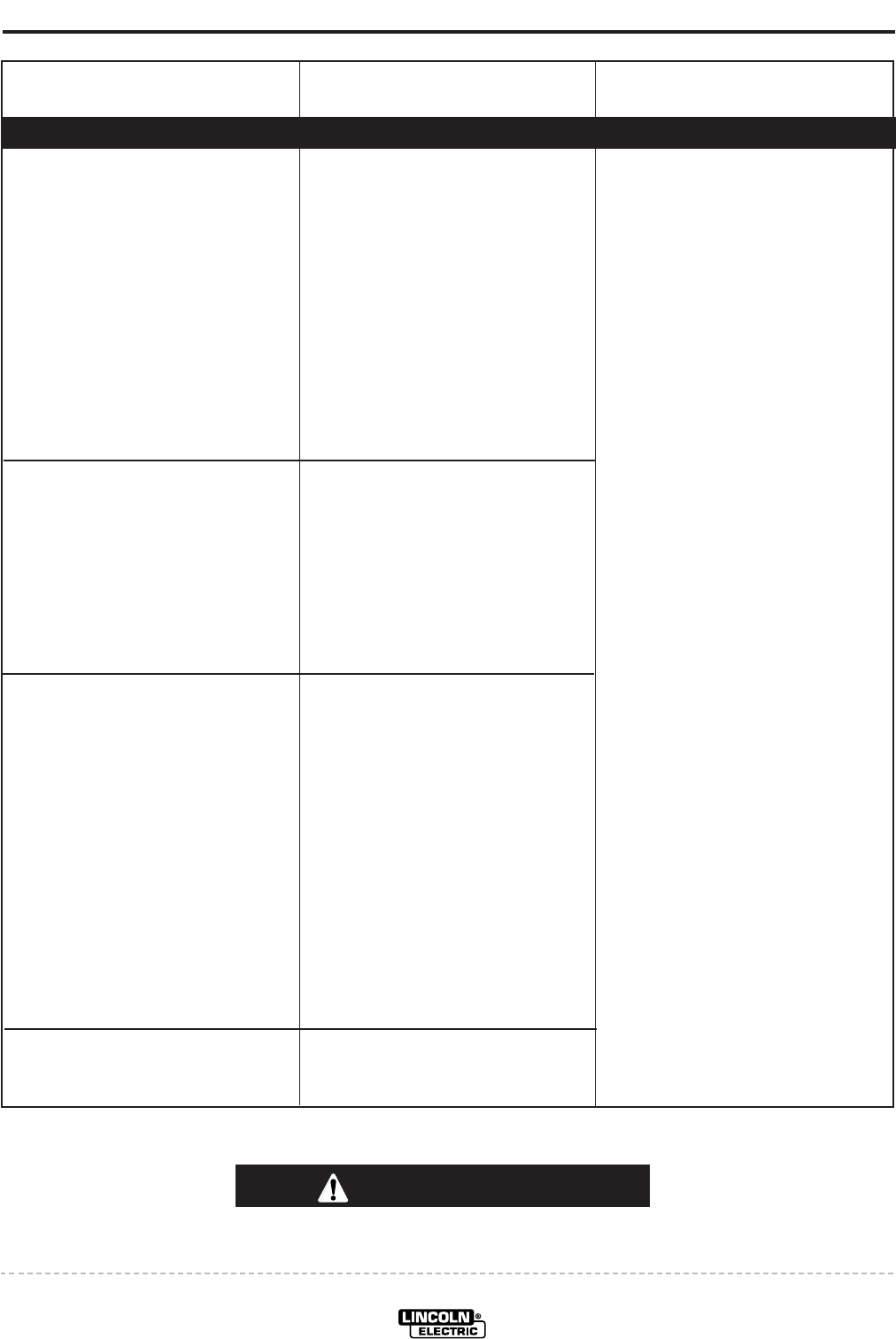

PROBLEMS

(SYMPTOMS)

POSSIBLE

CAUSE

RECOMMENDED

COURSE OF ACTION

OUTPUT PROBLEMS

Thermal LED is lit.

Machine won’t weld, can’t get any

output. (CR1 will not pull in.)

Arc loss fault on robot

1. Fan thermostat has opened.

Check for proper fan operation.

(Fan should run whenever main

power is on.) Check for material

blocking intake or exhaust lou-

vers, or for excessive dirt clog-

ging cooing channels in

machine.

2. Secondary rectifier thermostat

has opened. After machine has

cooled, reduce load, duty cycle,

or both. Check for material

blocking intake or exhaust lou-

vers.

1. Input voltage is too low or too

high. Make certain that input

voltage is proper, according to

the Rating Plate located on the

rear of the machine.

2. If the Thermal LED is also lit,

see “Yellow Thermal LED is Lit”

section.

Possibly caused by wire feeding

problem. Possible caus-

es/solutions are:

1. Problem - Conduit leading to the

wire feeder has bends or twists,

which can reduce the wire feed

speed.

Solution - Remove bends and

twists from conduit.

2. Problem – Conduit leading up to

the wire feeder from the wire reel

is too long.

Solution – Use a shorter length of

conduit

If all recommended possible areas

of misadjustments have been

checked and the problem persists,

contact your local Lincoln

Authorized Field Service Facility.