TABLE 5 DEVICENET CONNECTOR S5

Pin Lead # Function

2 894 +24vdc Devicenet

3 893 Common Devicenet+

4 892 Devicenet H

5 891 Devicenet L

F-4

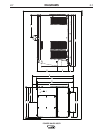

PIN, LEAD CONNECTOR DIAGRAMS

F-4

POWER WAVE® 655/R

TABLE 1 INTERFACE CONNECTOR S6

Pin Lead # Function

A 841 +15vdc Tach voltage

B 844 Tach common

C 842 Tach 1A differential signal

D 843 Tach 1B differential signal

E 845 Tach 2A differential signal

F 846 Tach 2B differential signal

G 847 Single Tach Input

H Reserved for future use

I 67B Voltage sense lead

J 539 Motor "+"

K 541 Motor "-"

L Reserved for future use

M Reserved for future use

N 521 +40vdc for solenoid

P 522 solenoid input

R Reserved for future use

S Reserved for future use

T 855A Shield ground to case

U Reserved for future use

V Reserved for future use

W Reserved for future use

X Reserved for future use

TABLE 2 WIRE FEEDER RECEPTACLE S1

Pin Lead # Function

A 53 Arclink L

B 54 Arclink H

C 67A Electrode Voltage Sense

D 52 Ground(0v)

E 51 +40vdc

TABLE 6 EXTERNAL I/O S7

Pin Lead # Function

1 851 +15vdc for Trigger group

2 852 Trigger input

3 853 Dual procedure input

4 854 4 Step input

5 855 +15vdc for cold inch group

6 856 cold inch forward

7 857 cold inch reverse

8 858 gas purge input

9 859 +15vdc for shutdown group

10 860 shutdown1 input

11 861 shutdown2 input

12 862 input B

TABLE 4 RS232 CONNECTOR S3

Pin Lead # Function

2 253 RS232 Receive

3 254 RS232 Transmit

4# S3 Pin5

5# S3 Pin4

6 ## S3 Pin20

20 ## S3 Pin6

7 251 RS232 Common

TABLE 3 VOLTAGE SENSE RECEPTACLE S2

Pin Lead # Function

3 21A Work Voltage Sense