Making Fillet Welds with Power Wave AC/DC 1000™ System

The future of welding is here.

®

APPLICATION

8/10

Welding Guide

WAVEFORM CONTROL TECHNOLOGY

TM

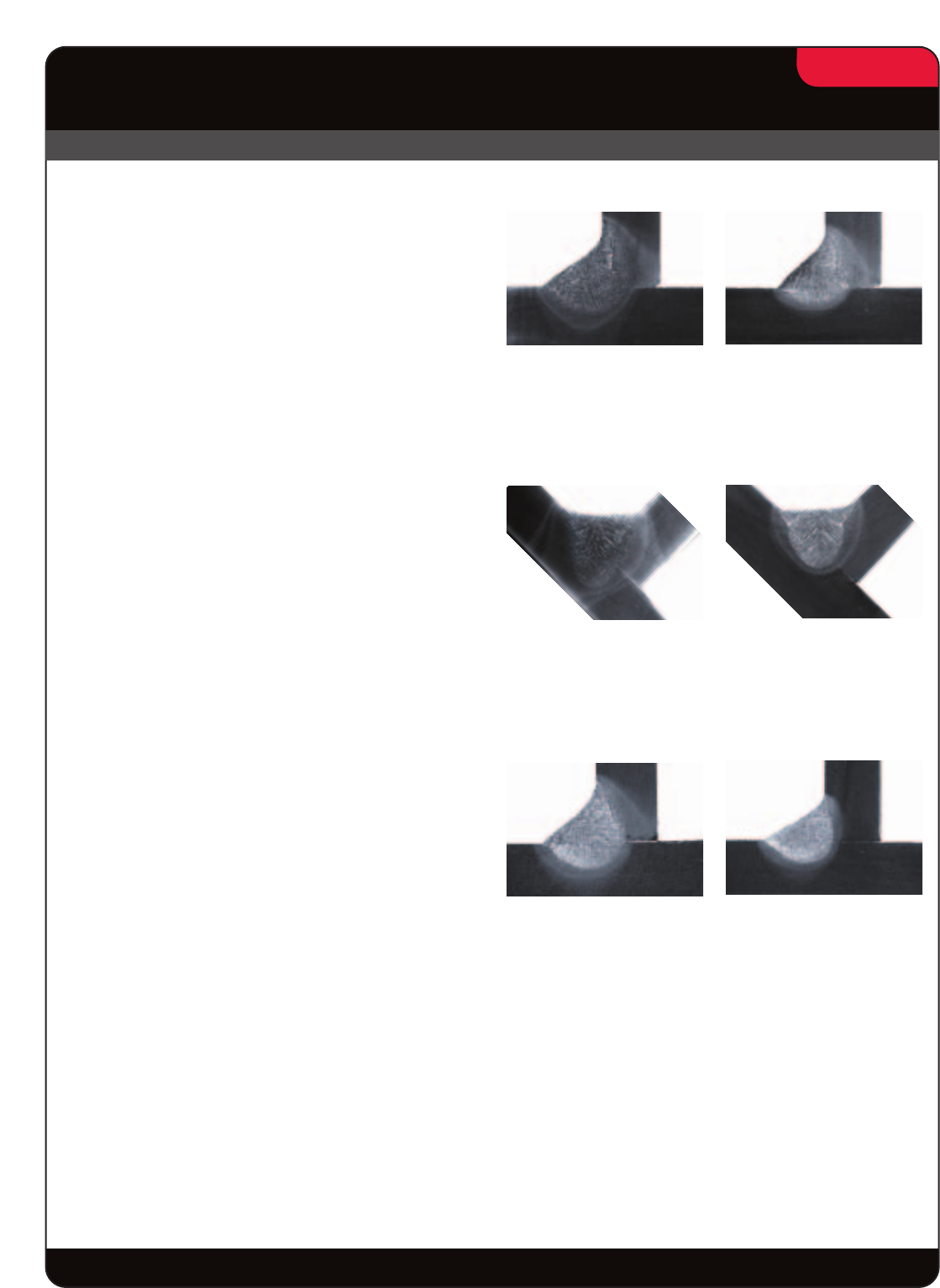

Figure 12

The weld on the left is DC+, 15 ipm travel.

The weld on the right is AC Balanced 25%, (-) 10% offset,

30 Hz., 21 ipm travel.

Figure 13

The weld on the left is with DC+, at 10.4 ipm travel.

The weld on the right is with AC 25% Balanced,

(-)20% Offset, 30Hz, at 15 ipm.

Figure 14

The weld on the left is with DC+.

The weld on the right is with AC 25% Balanced,

(-)10% Offset, 60Hz.

Some Fillet Weld Results`

A number of fillet welds made with the Power Wave

AC/DC 1000™ are shown as examples. All of these

welds comply with the AWS D1.1 Structural Steel

Code and the AWS D1.5 Bridge Code and those

codes that clone or refer to the AWS Codes.

All fillet welds conform to the acceptable size and

gauge size requirements of the code.There has been

no intent to match any specific mechanical properties,

however, the welding consumables used to produce

these welds are commonly used.

Figure 12: Horizontal, 5/16” (8mm) fillet welds, shows

an increase of 40% in travel speed over DC+. Both

welds made with 5/32” (4mm) diameter electrode at

527 amperes.

Figure 13: Flat positioned 1/2” (13mm) fillet welds

show an increase of 44% in travel speed over DC+.

Both welds made using 3/16” (4.8mm) diameter

electrode at 885 amperes.

Figure 14: Horizontal 1/4” (6mm) fillet welds, with an

increase of 32% in travel speed over DC+.