. A complete Parts List is available at www.MillerWelds.com

OM-278 Page 18

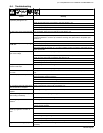

4-13. TIG (GTAW) Cable Connections

++ −

Gas Flowmeter/

Regulator

HIGH

INDUCTANCE

Optional HF Unit

! Turn Off power before making connections.

. For better performance for most GTAW applications, it is

recommended that electrode negative (DCEN) weld output

connections be made to the high Inductance weld output ter-

minal. Make connections as shown.

4-14. Remote 14 Receptacle RC8 Information

Socket Information

24 VOLTS AC

A 24 volts ac. Protected by supplementary protector CB2.

24 VOLTS AC

B Contact closure to A completes 24 volts ac contactor control circuit.

C Command reference; 0 to +10 volts dc (CC), +10 volts dc (CV).

REMOTE OUTPUT CONTROL

D Remote control circuit common.

E 0 to +10 volts dc input command signal from remote control.

F Current feedback; 1 volt per 100 amperes.

H Voltage feedback; 1 volt per 10 arc volts.

115 VOLTS AC

I 115 volts, 15 amperes, 60 Hz ac. Protected by supplementary protector CB1.

115 VOLTS AC

J Contact closure to I completes 115 volts ac contactor control circuit.

GND

K

G

Chassis common.

Circuit common for 24 and 115 volts ac circuits.

REMOTE POWER ON/OFF

*

To remote On/Off switch

REMOTE POWER ON/OFF

*

T

o

remote

O

n

/Off

sw

i

tc

h

.

REMOTE VOLTAGE SENSING

* Voltage sensing signal from Negative (−) weld output terminal.

REMOTE VOLTAGE SENSING

* Voltage sensing signal from Positive (+) weld output terminal.

* Not Used