. A complete Parts List is available at www.MillerWelds.com

OM-278 Page 22

SECTION 5 − OPERATION

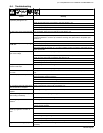

5-1. Controls (Non CE Models)

4

1 2

3

78

56

Ref. 184 939

1 Arc Force (Dig) Control

Control increases SMAW short-circuit

amperage which allows the operator to use

a very short arc length without sticking the

electrode.

Set control at 0 for normal welding amperage

and GTAW applications. Turn clockwise to

increase short-circuit amperage.

2 Process Selector Switch

• GMAW Mode: For use with flux Cored

(FCAW) or submerged arc (SAW) applica-

tions.

• SMAW (Hot Start On) Mode: Hot Start is

energized for Stick (SMAW). When Hot

Start is energized, higher short circuit am-

perage aids in arc starting. NOTE: use the

Positive (+) High Inductance weld output

terminal (see Section 4-9).

• SMAW (Hot Start Off) Mode: For use with

TIG (GTAW), scratch start only, or sub-

merged arc (SAW) applications. NOTE:

for GTAW, use the Positive (+) High Induc-

tance weld output terminal (see Section

4-9).

3 Amperage/Voltage Adjustment Control

When Process Selector switch is in the

SMAW/GTAW position, turn control clock-

wise to increase amperage. Read amperage

from outer scale of control. When Process

Selector switch is in the GMAW position, turn

control clockwise to increase voltage. Volt-

meter value changes as control knob is

turned. Control can be adjusted while

welding.

4 Digital Meters

With Process Selector switch in the SMAW/

GTAW position, digital meters will read 0

(zero) with contactor off. Digital meters will

display actual output voltage and amperage

with contactor on.

With Process Selector switch in the GMAW

position, voltmeter displays preset voltage

with contactor off. Voltmeter and ammeter

display actual output voltage and amperage

with contactor on.

5 Power Switch With Indicator Light

6 High Temperature Shutdown Light

7 Remote Amperage/Voltage Control

Switch

For front panel control, place switch in Panel

position. For remote control, place switch in

Remote position, and connect remote de-

vice (see Section 4-15).

8 Output Switch (Contactor)

For front panel control of output, place switch

in Panel position. For remote control of out-

put, place switch in Remote position, and

connect remote device (see

Section 4-15).

! Weld output studs are energized only

when Output switch is in On position,

or while welding.

! Turn Off power before connecting re-

mote device.