OM-495 Page 66

Return To Table Of Contents

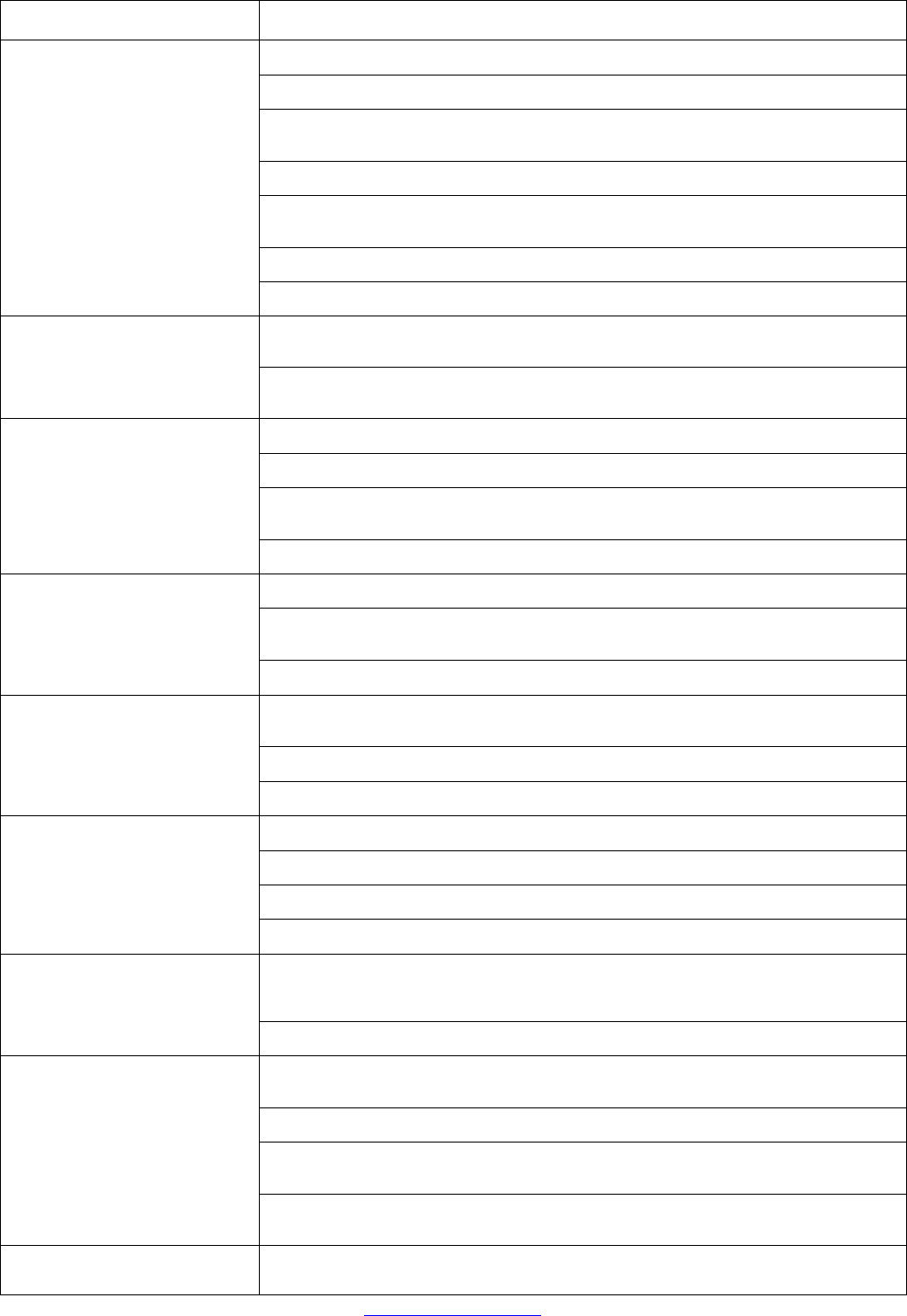

Trouble Remedy

Engine cranks but does not start. Press Magnetic Shutdown switch MS1 when starting engine.

Check fuel level.

Reset circuit breaker CB13 (see Section 9-7 or 10-8). Have Factory Authorized Service Agent check en-

gine wiring harness and components.

Check battery and replace if necessary. Check engine charging system according to engine manual.

On Deutz F3L912-powered units, allow circuit breaker CB14 to reset. Have Factory Authorized Service

Agent check fuel solenoid FS1 (see Section 10-8).

Have Factory Authorized Service Agent check control relay CR2, and fuel solenoid FS1.

Air in fuel system. See engine manual.

Engine starts, but stops when Magnetic

Shutdown switch is released.

When starting engine, continue holding Magnetic Shutdown switch until after engine indicator lights go

out.

Check oil level. Automatic shutdown system stops engine if oil pressure is too low or engine temperature

is too high (see Sections 5-9 and 11-1).

Engine hard to start in cold weather. Use optional starting aid switch (see Section 6-1 or 7-1).

Keep battery in good condition. Store battery in warm area off cold surface.

Use fuel formulated for cold weather (diesel fuel can gel in cold weather). Contact local fuel supplier for

fuel information.

Use correct grade oil for cold weather (see Section 9-2 or 10-2).

Engine suddenly stops. Check fuel level.

Check oil level. Automatic shutdown system stops engine if oil pressure is too low or engine temperature

is too high (see Sections 5-9 and 11-1).

See engine manual.

Engine slowly stopped and cannot be

restarted.

Check fuel level.

Check engine air and fuel filters (see Sections 9-3 and 9-6, or Sections 10-3 and 10-7).

See engine manual.

Battery discharges between uses. Turn Engine Control switch off when unit is not running.

Clean top of battery with baking soda and water solution; rinse with clear water.

Recharge or replace battery if necessary.

Periodically recharge battery (approximately every 3 months).

Engine idles, but does not come up to

weld speed (models with idle option

only).

Have Factory Authorized Service Agent check idle module PC7.

Check for obstructed throttle solenoid.

Engine does not run at idle speed

(models with idle option only).

CC models: place Stick/TIG Selection switch in Stick position.

CC/CV models: place Process/Contactor switch in any position but Remote-TIG.

Check for obstructed throttle solenoid.

Allow circuit breaker CB14 to reset. Have Factory Authorized Service Agent check throttle solenoid TS1

and linkage (see Section 9-7).

Have Factory Authorized Service Agent check idle module PC7, control relays CR3 and CR6, and current

transformer CT1.

Engine uses oil during run-in period;

wetstacking occurs.

Dry engine (see Section 13).