OM-611 Page 18

Return To Table Of Contents

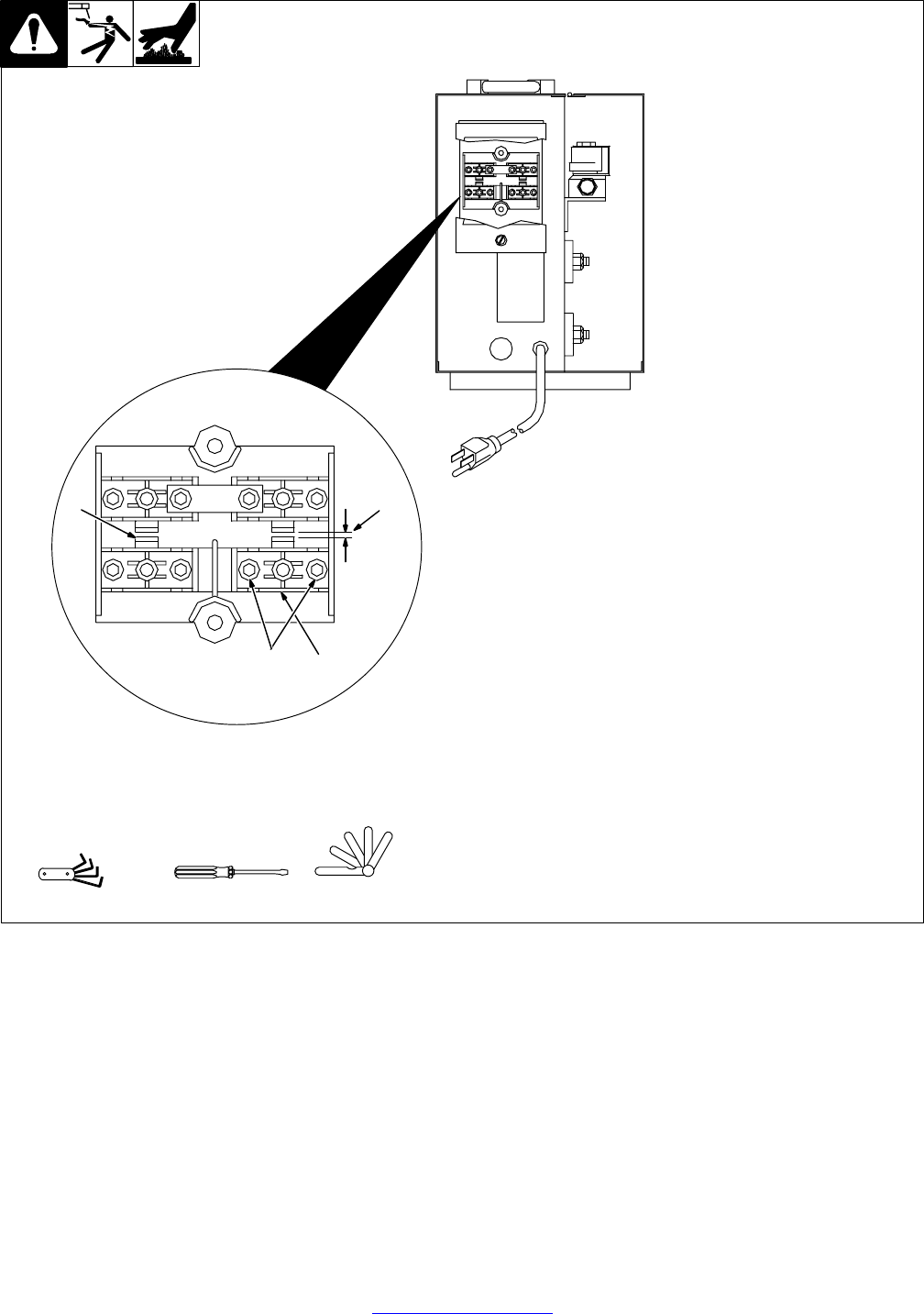

Ref. 098 956-G

Turn Off unit and welding power

source and disconnect input power.

Loosen screw on spark gap access

door and open.

1 Tungsten End Of Point

Do not clean or dress tungsten.

Replace point if tungsten end

disappears.

2 Spark Gap

Normal spark gap is 0.008 in (0.203

mm).

If spark gaps are okay, reinstall

door. If adjustment is needed, con-

tinue as follows:

3 Adjustment Screws

Loosen screws. Place gauge of

proper thickness in spark gap.

4 Pressure Point

Apply slight pressure at point until

gauge is held firmly in gap. Tighten

adjustment screws to 12 in/lbs

torque (overtightening will deform

plastic base). Repeat gauge adjust-

ment with other gap.

Close access door.

5/32 in

Tools Needed:

Rear Of Unit

0.008 in

(0.203 mm)

5-2. Adjusting Spark Gaps

1

4

3

2