OM-611 Page 25

Return To Table Of Contents

8-2. Preparing Tungsten Electrode For Welding

Y Grinding the tungsten electrode produces dust and flying sparks which can cause injury and start fires. Use

local exhaust (forced ventilation) at the grinder or wear an approved respirator. Read MSDS for safety infor-

mation. Consider using tungsten containing ceria, lanthana, or yttria instead of thoria. Grinding dust from

thoriated electrodes contains low-level radioactive material. Properly dispose of grinder dust in an environ-

mentally safe way. Wear proper face, hand, and body protection. Keep flammables away.

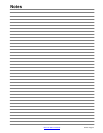

A. Preparing Tungsten For DC Electrode Negative (DCEN) Welding Or AC Welding With Inverter Machines

Ideal Tungsten Preparation − Stable Arc

2-1/2 Times

Electrode Diameter

1 Grinding Wheel

Grind end of tungsten on fine grit, hard

abrasive wheel before welding. Do not use

wheel for other jobs or tungsten can become

contaminated causing lower weld quality.

2 Tungsten Electrode

3 Flat

Diameter of this flat determines amperage

capacity.

4 Straight Ground

Grind lengthwise, not radial.

1

3

4

1 Tungsten Electrode

2 Balled End

Ball end of tungsten by applying AC amper-

age recommended for a given electrode

diameter (see Section 8-1). Let ball on end of

the tungsten take its own shape.

B. Preparing Tungsten For Conventional AC Welding

1 − 1-1/2 Times

2

Electrode Diameter

Causes Wandering Arc

2

1

Wrong Tungsten Preparation

Radial Grinding

SECTION 9 − GUIDELINES FOR TIG WELDING (GTAW)

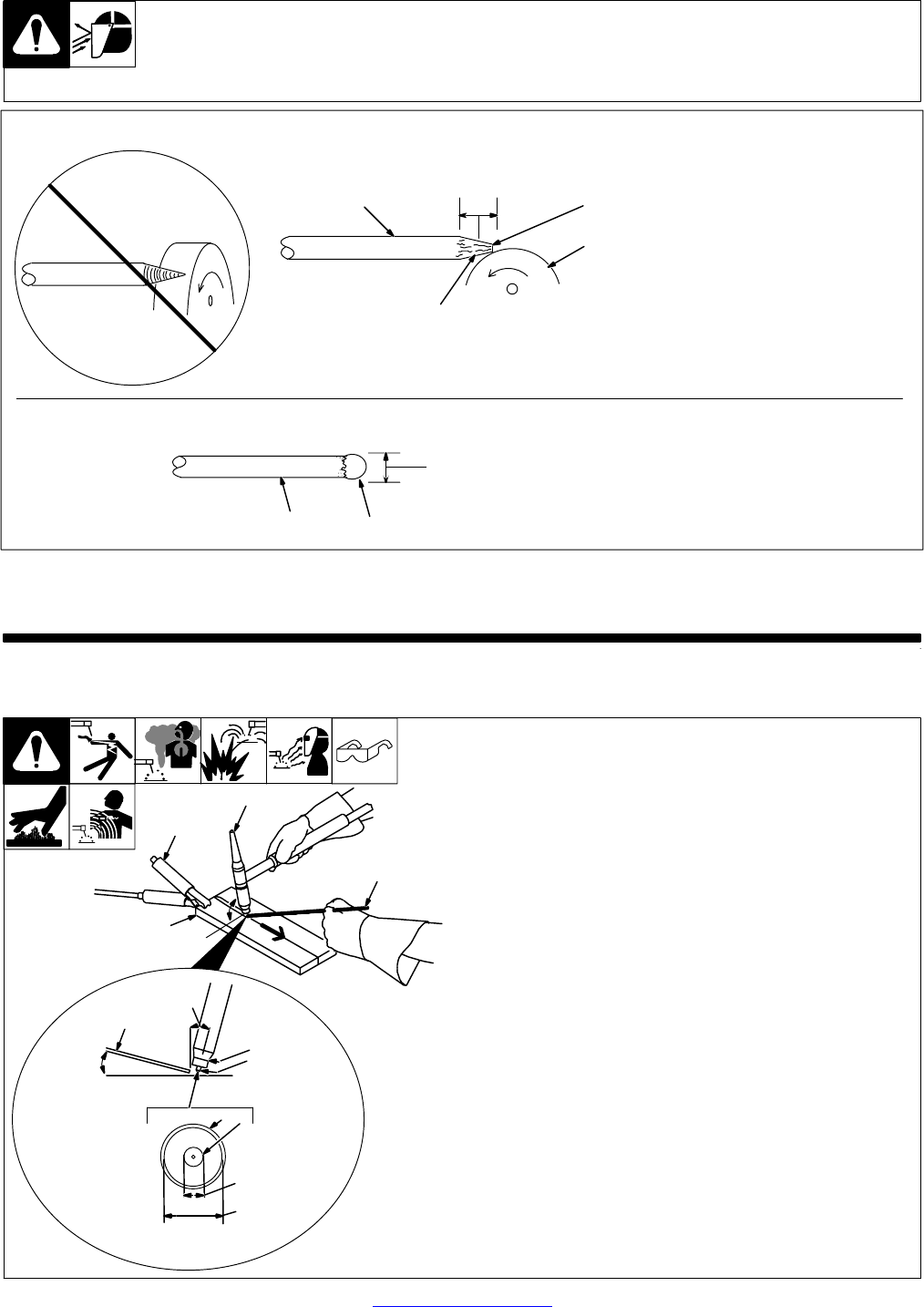

9-1. Positioning The Torch

Y Weld current can damage electronic parts in vehicles. Discon-

nect both battery cables before welding on a vehicle. Place work

clamp as close to the weld as possible.

. For additional information, see your distributor for a handbook on the

Gas Tungsten Arc Welding (GTAW) process.

1 Workpiece

Make sure workpiece is clean before welding.

2 Work Clamp

Place as close to the weld as possible.

3 Torch

4 Filler Rod (If Applicable)

5 Gas Cup

6 Tungsten Electrode

Select and prepare tungsten according to Sections 8-1 and 8-2.

Guidelines:

The inside diameter of the gas cup should be at least three times the

tungsten diameter to provide adequate shielding gas coverage. (For

example, if tungsten is 1/16 in diameter, gas cup should be a minimum of

3/16 in diameter.

Tungsten extension is the distance the tungsten extends out gas cup of

torch.

The tungsten extension should be no greater than the inside diameter of

the gas cup.

Arc length is the distance from the tungsten to the workpiece.

1

10−25°

10−15°

6

2

3

4

90°

4

5

3/16 in

1/16 in

6

5

Bottom View Of Gas Cup

Ref. 161 892