. Complete Parts List available at www. MillerWelds.com

OM-228 042 Page 20

5-7. Weld Process/Polarity Table

Weld Process

Weld Polarity

Cable Connections

W

e

ld P

rocess

W

e

ld P

o

l

ar

i

ty

Wire Drive Lead Work Clamp Lead

GMAW − Solid wire with shield-

ing gas

DCEP − Reverse polarity Connect to positive (+) out-

put terminal

Connect to negative (−) output

terminal

FCAW − Self-shielding wire −

no shielding gas

DCEN − Straight Polarity Connect to negative (−)

output terminal

Connect to positive (+) output

terminal

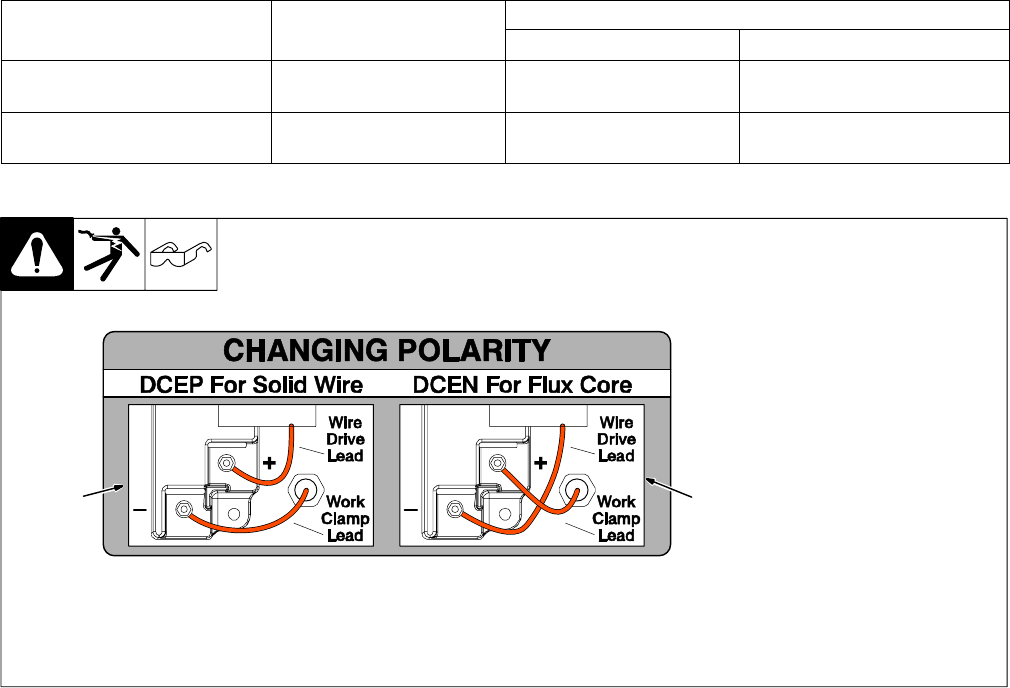

5-8. Changing Weld Polarity

. Connection hardware must be

tightened with proper tools. Do

not just hand tighten hardware.

A loose electrical connection

will cause poor weld perfor-

mance and excessive heating

at the terminal block.

1 Lead Connections For Direct

Current Electrode Negative

(DCEN)

2 Lead Connections For Direct

Current Electrode Positive

(DCEP)

Always read and follow wire

manufacturer’s recommended po-

larity, and see Section 5-7.

Close door.

1

2

Ref. 230 748-B