4 5

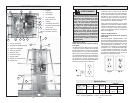

8. Never cut a workpieces with a width

smaller than that of the saw carriage.

Proper support for the workpiece must

be maintained to insure safety. When

the carriage moves over the workpiece,

it would be impossible to safely support

the workpiece for the cut. Use a tool

better suited for these applications.

9. Always wait for blade to stop com-

pletely before changing positions.

Unplug the tool before transporting or

moving it.

10. Do not place hands on or under saw

carriage or in the path of the blade.

Do not attempt to retrieve a piece of

material that is cut off while the blade is

rotating.

11. Make workshop child proof with pad-

locks, master switches, or by removing

starter keys. See "Lock-Off Feature".

12. Replace guards after blade change.

Maintain guards in working order.

13. Direction of feed. Feed work into a

blade or cutter against the direction of

rotation of the blade or cutter only.

14. Causes and Operator Prevention of

KICKBACK:

KICKBACK is a sudden reaction to

a pinched, bound or misaligned saw

blade, causing an uncontrolled saw to

lift up and out of the workpiece toward

the operator.

When the blade is pinched or bound

tightly by the kerf closing down, the

blade stalls and the motor reaction

drives the unit rapidly back toward the

operator when cross-cutting and throws

out the workpiece if ripping.

If the blade becomes twisted or mis-

aligned in the cut, the teeth at the back

edge of the blade can dig into the top

surface of the wood causing the blade

to climb out of the kerf and jump back

toward operator.

KICKBACK is the result of tool mis-

use and/or incorrect operating pro-

cedures or conditions and can be

avoided by taking proper precautions as

given below:

• Keep blade clean and sharp. Un-

sharpened or improperly set blades

produce narrow kerf causing excessive

friction, blade binding and KICKBACK.

Any blade with a small set, even though

sharp, may be likely to kick back. A dull

blade encourages the operator to force

the saw, causing reduced control and

blade binding. The excessive friction

generated can cause the blade to warp

or bind. Use only blades which are rec-

ommended for use with your tool. Do not

use blades with incorrect size or shaped

mounting holes. Never use defective

or incorrect blade washers or bolts. Be

sure the blade bolt is tight. Select the

proper blade for the application. Blade

speed specifi cations must be at least as

high as nameplate RPM.

• Do not force tool. Let the saw do the

work. A saw is more readily controlled

and will do a better job when used in the

manner for which it was designed.

• Stay alert. Watch what you are doing

and use common sense. Do not allow

yourself to be distracted. Do not oper-

ate tool when tired, under the infl uence

of drugs or alcohol. Hold the tool or

material fi rmly and exercise control at

all times. Position yourself and co-work-

SPECIFIC SAFETY RULES

1. Maintain labels and nameplates.

These carry important information.

If unreadable or missing, contact a

MILWAUKEE service facility for a free

replacement.

2. WARNING! Some dust created by

power sanding, sawing, grinding, drill-

ing, and other construction activities

contains chemicals known to cause

cancer, birth defects or other reproduc-

tive harm. Some examples of these

chemicals are:

• lead from lead-based paint

• crystalline silica from bricks and cement

and other masonry products, and

• arsenic and chromium from chemically-

treated lumber.

Your risk from these exposures varies,

depending on how often you do this

type of work. To reduce your exposure

to these chemicals: work in a well ven-

tilated area, and work with approved

safety equipment, such as those dust

masks that are specifi cally designed to

fi lter out microscopic particles.

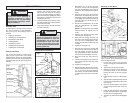

3. Handle the counterbalance with care.

The cable is under tension. Always as-

semble cable to saw carriage before

removing cable clip. Do not pull on cable

by hand or attempt to disassemble or

repair the counterbalance.

4. Do not defeat the guards or operate

the tool without the guards in place.

5. Do not use push sticks. Push sticks or

the workpiece can kick back, cause the

blade to pinch, or become caught in the

blade and be thrown from the tool.

6. Cross-cutting (vertical cutting) must

always be done from the top down.

Saw carriage should be raised to the

uppermost position on the guide tubes

and locked into position with the carriage

lock whenever the tool is not in use. See

"Cross-Cutting".

7. Ripping (horizontal cutting) must rip-

ping must always be done by moving

the workpiece through the saw in the

direction of the arrow on the saw mo-

tor. Saw carriage should be raised to the

top of the guide tubes and locked into

position with the carriage lock whenever

tool is not in use. See "Rip Cutting".

ers out of the kick back path. Repetitive

cuts which lull the operator into careless

movements can also cause kick back. A

brief "stretch" may be all that is neces-

sary to avoid a problem.

• When blade is binding, or when inter-

rupting a cut for any reason, turn the

switch off and hold the saw motion-

less in the material until the blade

comes to a complete stop. Never

attempt to remove the saw from the

work or pull the saw backward while

the blade is in motion or KICKBACK

may occur. Investigate and take cor-

rective actions to eliminate the cause

of blade binding.

• To remove the blade after stopping

mid-cut, allow the blade to stop and

then back up the saw (cross-cutting) or

board (rip-cutting).

• When restarting a saw in the work-

piece, center the saw blade in the

kerf and check that saw teeth are

not engaged into the material. If

saw blade is binding, it may walk up or

KICKBACK from the workpiece as the

saw is restarted.

• Avoid cutting nails. Inspect for and

remove all nails before cutting.

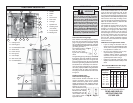

Amperes

Double Insulated

Symbology

Canadian Standards

Association

Underwriters

Laboratories, Inc.

Volts Alternating

Current

No Load Revolutions

per Minute (RPM)

Speed

5800

Volts

AC

120

Cat.

No.

6480-20

Specifi cations

Amps

15

Do not place hands on or under saw

carriage or in the path of the blade.

Do not expose to rain or use in

damp locations.

Blade

Size

8-1/4"

Arbor

5/8"

Thickness

1-3/4"

Height

50"

Capacity *

* For additional limitations, see the "Rip Cutting" and "Cross-cutting" sections.