16 17

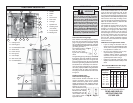

Fig. 15

Rip ruler

Rip Cutting

A rip cut is a horizontal cut that can be done

from the LEFT TO THE RIGHT or from the

RIGHT TO THE LEFT, but the work piece

must always be moved through the saw

in the direction of the arrow on the saw

motor.

MILWAUKEE recommends using the Hold

Down Bar Kit for frequent cutting of workpiec-

es thinner than 1/4" (see "Accessories").

The minimum length recommended for rip

cuts is 2-1/2' (work supported by four roll-

ers). The same size applies if you use the

Midway Fence Kit.

For easier cutting and best performance,

MILWAUKEE recommends using the Exten-

sion Kit when rip-cutting workpieces longer

than 6' (see "Accessories"). Do not rip-cut

workpieces that exceed 8'.

1. Select ripping from the left or right,

based on preference. Rotate the saw

motor to the ripping position (Fig. 15).

To rotate the motor, pull out the indexing

pins and rotate the saw motor. Lock the

indexing pins into the preset holes in

the saw carriage. The pins are spring-

loaded and should snap into place.

Be sure to shield bystanders from the

tool.

7. When the motor has reached full speed,

slowly move the workpiece through the

saw in the direction of the feed arrow

on the saw motor. Avoid placing your

hands, clothing or body parts under the

saw carriage. Do not look directly down

the line of cut because dust and debris

are generated during operation. Do not

use push sticks.

8. After the cut is completed, turn the tool

off and wait for the blade to come to a

complete stop.

9. Pull the scrap material and the fi nished

workpiece away from the tool.

10. Return the saw carriage to the upper-

most position on the guide tubes.

11. Tighten the carriage lock.

NOTE: When done ripping, return the car-

riage to the cross-cut position.

Indexing

pins

WARNING

To reduce the risk of injury, ripping

must always be done by moving

the workpiece through the saw in

the direction of the arrow on the

saw motor.

2. Select the saw height based on your

workpiece, following the measure on

the rip ruler.

3. Tighten the carriage lock securely.

4. Plug in the tool.

5. Start the motor and allow it to reach full

speed before beginning the cut.

6. Place the workpiece on the rollers. Do

not to drop the material; this may knock

the rollers out of alignment or damage

the rollers.

WARNING

To reduce the risk of injury and

damage to the tool, do not use push

sticks. Push sticks or the workpiece

can kick back, cause the blade to

pinch, or become caught in the

blade and be thrown from the tool.

WARNING

To reduce the risk of injury, always

shield bystanders from the tool.

Never look down the line of cut be-

cause dust and debris are generated

during operation.

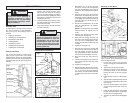

Maintaining Tools

Keep your tool in good repair by adopting a

regular maintenance program. Before use,

examine the general condition of your tool.

Inspect guards, switches, tool cord set and

extension cord for damage. Check for loose

screws, misalignment, binding of moving

parts, improper mounting, broken parts and

any other condition that may affect its safe

operation. If abnormal noise or vibration oc-

curs, turn the tool off immediately and have

the problem corrected before further use.

Do not use a damaged tool. Tag damaged

tools “DO NOT USE” until repaired (see

“Repairs”).

Under normal conditions, relubrication is not

necessary until the motor brushes need to

be replaced. After six months to one year,

depending on use, return your tool to the

nearest MILWAUKEE service facility for the

following:

• Lubrication

• Brush inspection and replacement

• Mechanical inspection and cleaning

(gears, spindles, bearings, housing,

etc.)

• Electrical inspection (switch, cord,

armature, etc.)

• Testing to assure proper mechanical and

electrical operation

WARNING

To reduce the risk of injury, always un-

plug your tool before performing any

maintenance. Never disassemble the

tool or try to do any rewiring on the

tool's electrical system. Contact a

MILWAUKEE service facility for ALL

repairs.

WARNING

To reduce the risk of injury, electric

shock and damage to the tool, never

immerse your tool in liquid or allow a

liquid to fl ow inside the tool.

MAINTENANCE

Cleaning

Clean dust and debris from vents. Keep

the tool handles clean, dry and free of oil

or grease. Use only mild soap and a damp

cloth to clean your tool since certain cleaning

agents and solvents are harmful to plastics

and other insulated parts. Some of these

include: gasoline, turpentine, lacquer thinner,

paint thinner, chlorinated cleaning solvents,

ammonia and household detergents con-

taining ammonia. Never use fl ammable or

combustible solvents around tools.

Repairs

If your tool is damaged, return the entire tool

to the nearest service center.

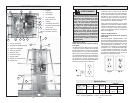

Making Cuts Less than 1"

When making cuts that are less than 1",

the chatter guard (located inside the blade

guard) must be on the workpiece and not on

the cut-off piece. If the chatter guard is on the

cut-off piece, it will jam on the workpiece and

prevent the carriage from continuing through

the cut. If the saw jams, turn the tool OFF

and wait for the blade to stop. Then back the

saw out of the cut.

Lock-Off Feature

Unplug the tool before installing the padlock.

There is a hole in the switch through which a

padlock (not supplied with tool) will fi t to lock

the tool when it is not in use. Use a padlock

with a 1-1/2" shackle, 5/16" diameter (such

as the Master Lock 1KALJ).

Lubricating Guide Tubes

The saw carriage should raise itself from the

bottom to the top of the guide tubes. How-

ever, if the tubes become caked with dust

or debris, the saw carriage may get stuck or

it may not slide smoothly. Periodically clean

the guide tubes with a damp cloth, following

the directions under "Cleaning". Then, use a

dry lubricant such as PTFE or spray silicone.

Other lubricants will cause dust and debris

to collect on the tubes, contaminating the

bearings.