HPLA/HPHA-SERIES 46" WALK-BEHIND TROWEL — OPERATION AND PARTS MANUAL — REV. #6 (07/06/10) — PAGE 19

HPLA/HPHA-SERIES 46" TROWEL — ASSEMBLY AND INSTALLATION

Assembly and Installation

Before the trowel can be put into operation there are some

components that must be installed before the trowel can be used.

This section provided general instructions on how to install those

components. Instruction sheet P/N 20485 provides further details

for the handle assembly.

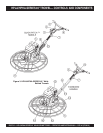

Handle Tube Installation (All Models)

1. Install the

handle tube

to the gearbox as shown in (Figure 5).

The mounting hardware should be contained in the shipping

container.

Figure 5. Handle Tube Installation

CAUTIONCAUTION

CAUTIONCAUTION

CAUTION

The Quick-Pitch™ handle is spring loaded,

personal injury or damage could result from

improper handling or installation. Be careful

when installing this component.

2. On Quick-Pitch™ models, pivot the

T-handle

back

(full pitch) (Figure 6). This will relax the spring inside the

handle tube. On either model, spread the handle bar ends

just enough to engage the teeth on the handle tube. Attach

the hand wheel assembly, position handlebar to desired

location, and tighten hand wheel firmly.

Figure 6. Handlebar Installation

2. Feed the throttle cable through the cable housing.

3. Connect the throttle cable to the engine. (Figure 8). There

should be a piece of wire installed on the trowel to show

where to route the throttle cable. When connecting the cable

housing, make sure that no more than

1/4" (6.4mm)

of the

cable housing protrudes past the housing clamp on the

engine.

Figure 8. Throttle Cable Connection

CABLE HOUSING

ENGINE

THROTTLE

LEVER

SWIVEL STOP

SCREW

THROTTLE

CABLE END

CABLE

HOUSING

CLAMP

Figure 7. Throttle

Throttle Cable Installation

1. Place the throttle lever (Figure 7) to the idle position.

Considerable force may be

required when moving the Quick-

Pitch™ T-handle forward or

backward.

NOTE