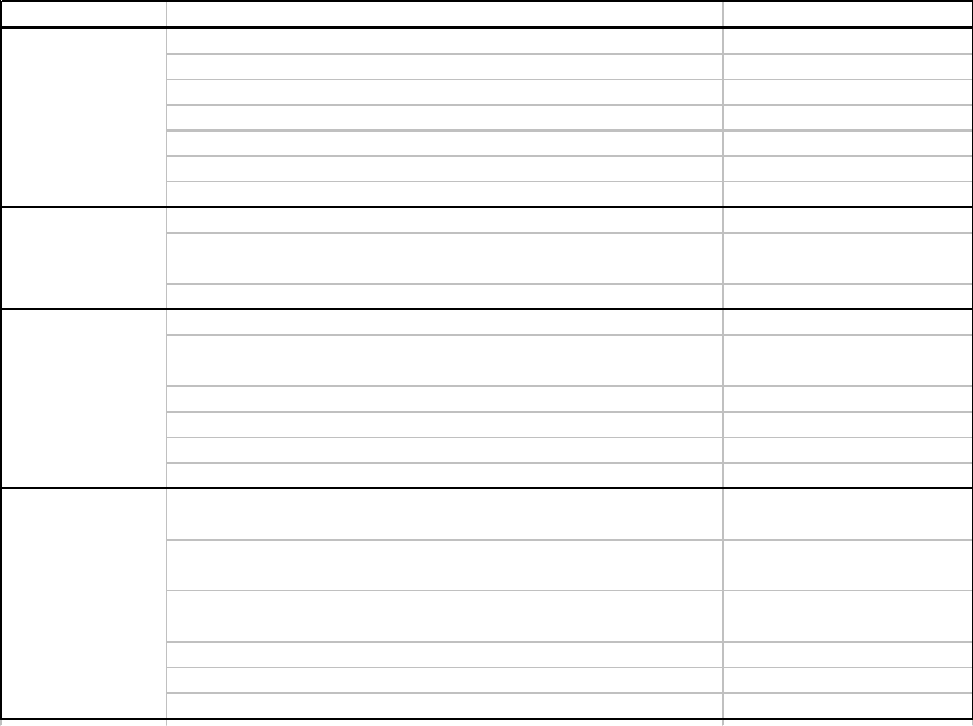

25

P/N: 307271

INTERVAL REQUIRED MAINTENANCE REFERENCE

1. Check compressor system fluid level.

2. Check radiator coolant level in coolant recovery tank.

3. Check fuel supply after running.

4. Check air filter maintenance indicator (if equppied).

5. Check for fuel, oil, air, and water leaks.

6. Check battery mounting for security.

7. Drain water and sediment from fuel tank. Drain at bottom of tank.

1. Clean return line orifice after initial start only.

2. Drain water from compressor oil reservoir. More frequent

draining may be required under high humidity conditions.

Drain at bottom of reservoir.

3. Inspecting lifting frame (and before each lift).

1. Change air end fluid and fluid filter elements.

2. Clean battery terminals, check battery hold-downs and

cables for wear.

3. Check air filter piping, fittings, and clamps.

4. Check radiator hoses and clamps.

5. Check engine and air end mounts.

6. Check fan belt tension.

1. Install new air filter elements (shorter intervals may be

necessary under dusty conditions).

2. Check all door gaskets, hinges, and latches to maintain

acoustics seal.

3. Drain engine radiator coolant. Clean and flush cooling

system. Refill with coolant.

4. Check engine and compressor shut down switches.

5. Check reservior pressure relief valve.

6. Install new fuel filter and water separator elements

EVERY 10

HOURS OR

DAILY

EVERY 50

HOURS OR

WEEKLY

EVER 500

HOURS

EVERY 1000

HOURS

4.17 MAINTENANCE SCHEDULE CHART

NOTICE: Check engine operator’s manual for required service and service intervals.