30

P/N: 307271

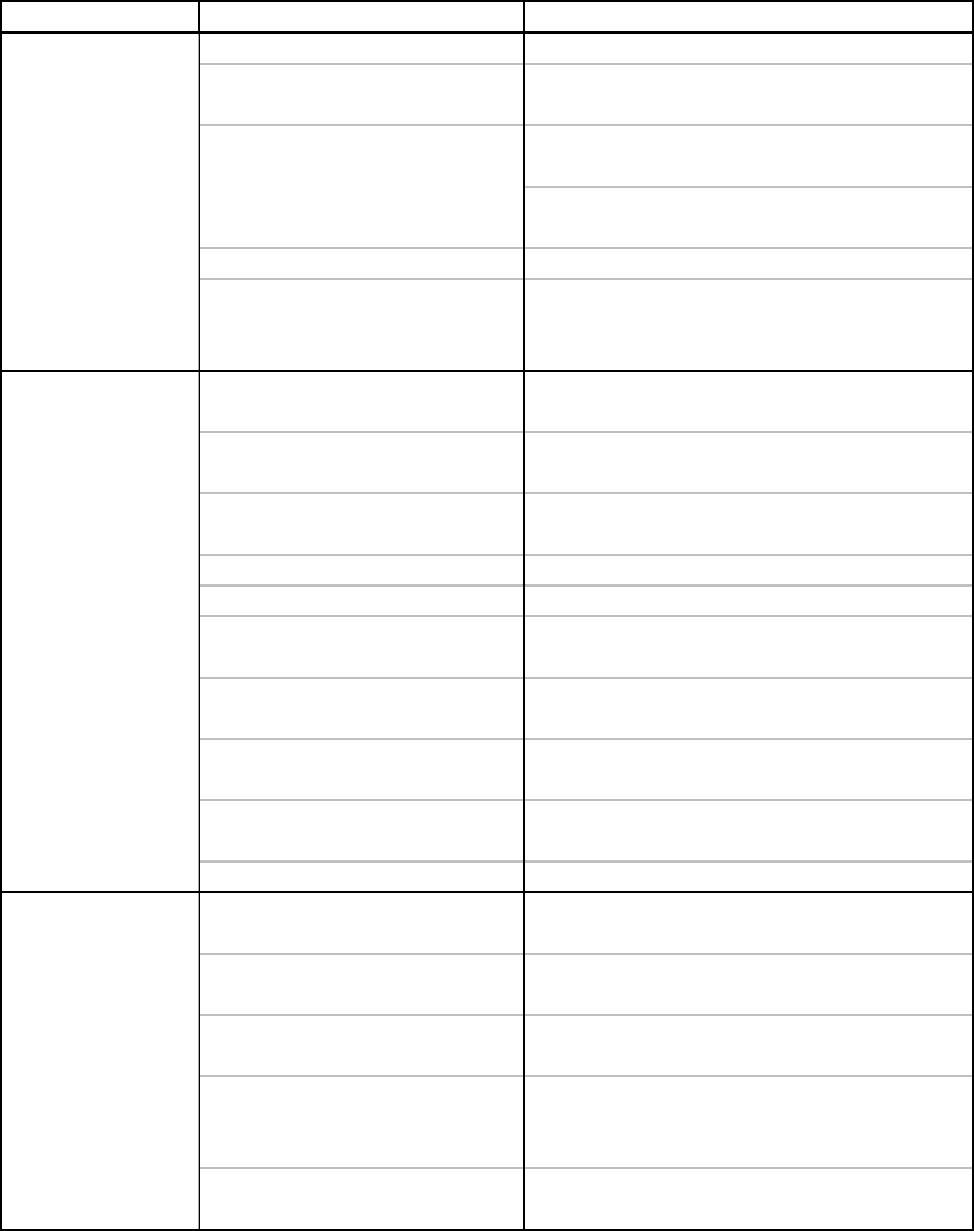

SYMPTOM CAUSE REMEDY

Oil reserve over filled. Drain to the proper level.

Leak in the compressor oil

system.

Check all piping lines and connections;

repair as necessary.

a. Check scavenge line and its check

valve for restrictions; clear as necessary.

b. Make sure that the scavenge line

reaches the bottom of the separator.

Separator element damaged. Replace the element.

Compressor undersized for

the air requirement.

Operating at low pressures increases the

oil carry over; recheck the load

requirements.

Unit being operating in an

area with limited fresh air.

Reposition the unit or open up the

confinement.

Fan belts are loose or broken. Tighten or replace.

Dirt build up on the coolers.

Clean the cooler thoroughly. Be careful

not to damage the fins.

Compressor level low. Check and fill to proper level.

Compressor oil filter dirty. Replace the filter.

Thermostatic valve

malfunctioning.

Clean or replace the element.

Restriction in the compressor

oil lines.

Clean or replace the lines.

Restriction inside the oil

cooler.

Clean internal tubes of the cooler.

Operating the compressor

with the panels removed.

Reinstall panels.

Coolant level low. Add coolant to the proper level.

Leaks in the fuel system.

Check all the fuel lines and connections;

repair or replace as necessary.

Engine not at correct

operating speed.

Adjust the engine to its proper speed.

Pressure to regulator set too

high.

A

djust regulator to correct pressure for the

unit.

Engine air intake is restricted.

Inspect the air intake system checking for

any restriction; clean repair or replace as

necessary.

Incorrect injection timing.

Adjust to specifications in the engine

manual.

High fuel

consumption

Oil scavenge line not removing

the oil from the separator.

Excessive

compressor oil

consumption.

Compressor

overheating