-

10

-

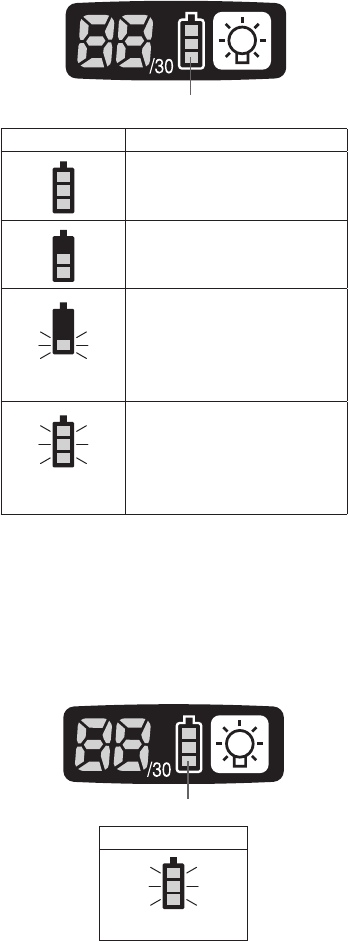

(2) The battery indication lamp

• Use the battery indication lamp to check

how much power is left in the battery.

•

Battery life varies slightly with ambient tem-

perature and battery characteristics. The

lamp is designed to provide a rough indica-

tion of remaining battery life.

Battery indication lamp

Indicator Battery status

Fully charged

Approx. 40% or less

remaining

Flashing

Flashing

Approx. 20% or less

remaining (indicates need

to recharge battery)

The battery pack will need

to be charged soon.

Flashing

No charge

The battery pack needs to

be charged.

(The tool’s automatic

power-off function will

activate at this stage.)

Automatic power-off function

• The automatic power-off function is designed

to prevent a loss of tightening torque due to

reduced battery voltage. Once it has been

activated, the tool will not operate until the

battery pack has been charged (or replaced

with a fresh unit), even if the trigger is

depressed.

Battery indication lamp

Indicator

Flashing

NOTE:

• All 3 bars on the battery indication lamp

will flash when the automatic power-off

function is activated.

•

When the battery indication lamp begins

flashing, the battery pack should be

charged (or replaced with a fresh unit)

immediately.

•

Be sure to fully charge the battery pack

in question after activation of the auto-

matic power-off function. Failure to do

so may prevent the automatic power-off

function from being properly deactivated.

(3) The torque control function

• The torque control function calculates the

load from the motor’s rotational angle during

the hammer impact and determines that the

bolt has been properly seated when a pre-

set load value is exceeded. Driving is then

automatically stopped after a preset number

of impacts have been delivered to the bolt.

CAUTION:

•

Always check the tool’s tightening

torque before use. Improper tool opera-

tion may result in excessive or inad-

equate tightening.

CAUTION:

•

Always operate the tool with the switch

fully engaged. The torque control func-

tion will not operate when the switch is

not sufficiently engaged, preventing the

tool from stopping automatically.

•

In work where a heavy load comes to

bear during tightening, the load may be

interpreted as the seating of the bolt,

preventing the bolt from being com-

pletely tightened.

•

Repeated tightening of the same bolt

may break the bolt or deform the mate-

rial into which the bolt is being driven as

a result of excessive tightening.

•

The tightening torque value and preci-

sion vary with factors such as the mate-

rial into which the bolt is being driven

and the condition of the socket being

used. Adjust the torque as necessary

for the work being performed. Bolt tight-

ening torque varies due to the factors

described below.

1) Bolt

•

Bolt diameter: Tightening torque gener-

ally increases with bolt diameter.

•

Torque coefficient (indicated by the bolt

manufacturer), grade, length, etc.