16

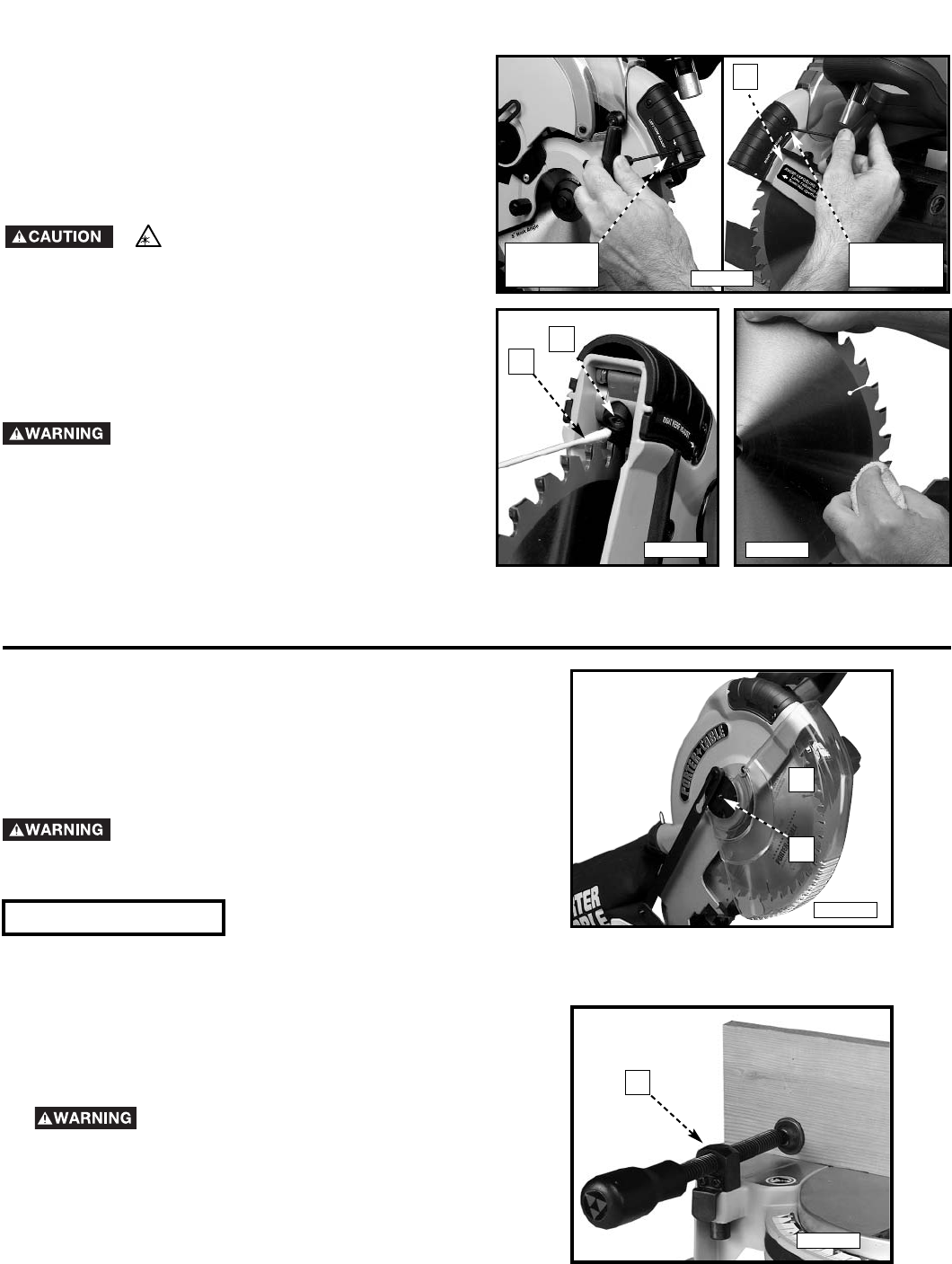

1. Carefully clean sawdust from each laser lens (A) Fig. J with

a cotton swab (B). Do not use solvents of any kind since

they may damage the lens. Avoid touching sharp points of

the saw blade with your hands or fingers. Dust build-up can

block the laser and prevent it from accurately indicating the

line-of-cut.

2. Remove the blade from the saw and clean pitch build-up from the blade (Fig. K) Pitch build-up can block the laser and

prevent it from accurately indicating the line-of-cut.

16

ADJUSTING LOWER BLADE GUARD

After an extended period of use, the movable lower blade guard

(A) Fig. 32 may not operate smoothly when the cuttinghead is

lowered. You can correct this by adjusting the nut (B) until the

lower blade guard (A) moves freely

.

Do not over-tighten the nut as this can make

the guard hard to move.

A

B

MACHINE USE

Fig. 32

LEFT LASER

ADJUSTMENT

SCREW

Fig. H

TO SET LEFT and RIGHT KERF ADJUSTMENT

RIGHT LASER

ADJUSTMENT

SCREW

L

A

B

Fig. J

Fig. K

1. Use the 1/8" hex wrench to turn the left or right kerf

adjustment screws and set the laser lines to either side of

the test cut (Fig. G). To adjust the left line, turn the left kerf

adjustment screw counter-clockwise to move the line

toward the blade and clockwise to move the line away from

the blade. To adjust the right line turn the right kerf

adjustment screw counter-clockwise to move the line

toward the blade and clockwise to move the line away from

the blade. (Fig. H)

Observe the laser CAUTION label (L)

Fig. H.

2. Remove the padlock and use the saw normally.

TwinLaser

™

MAINTENANCE

For best laser performance, perform the following maintenance

regularly:

DISCONNECT THE MACHINE FROM

THE POWER SOURCE.

TYPICAL OPERATIONS AND HELPFUL HINTS

1. Before cutting, make certain the cutting arm and table

are at their correct settings and firmly locked in place.

2. Place the workpiece on the table and hold or clamp it

firmly against the fence. Fig. 33 illustrates the work

clamp (A). The clamp (A) can also be used on the right

side of the machine.

3. If the position or size of the workpiece

causes your hand to be in the “Hazard Zone”, use

the work clamp to secure the workpiece. Keep your

hands out of the “Hazard Zone”.

4. For best results, cut at a slow, even cutting rate.

5. Never attempt freehand cutting (wood that is not held

firmly against the fence and table).

Fig. 33

A