11

WARNING: After installing knives, re-check

all gib screws. Loose gib screws can result

in knives being thrown out of the cutterhead,

causing severe damage to the machine and

possible serious or fatal injury to the operator

or bystanders.

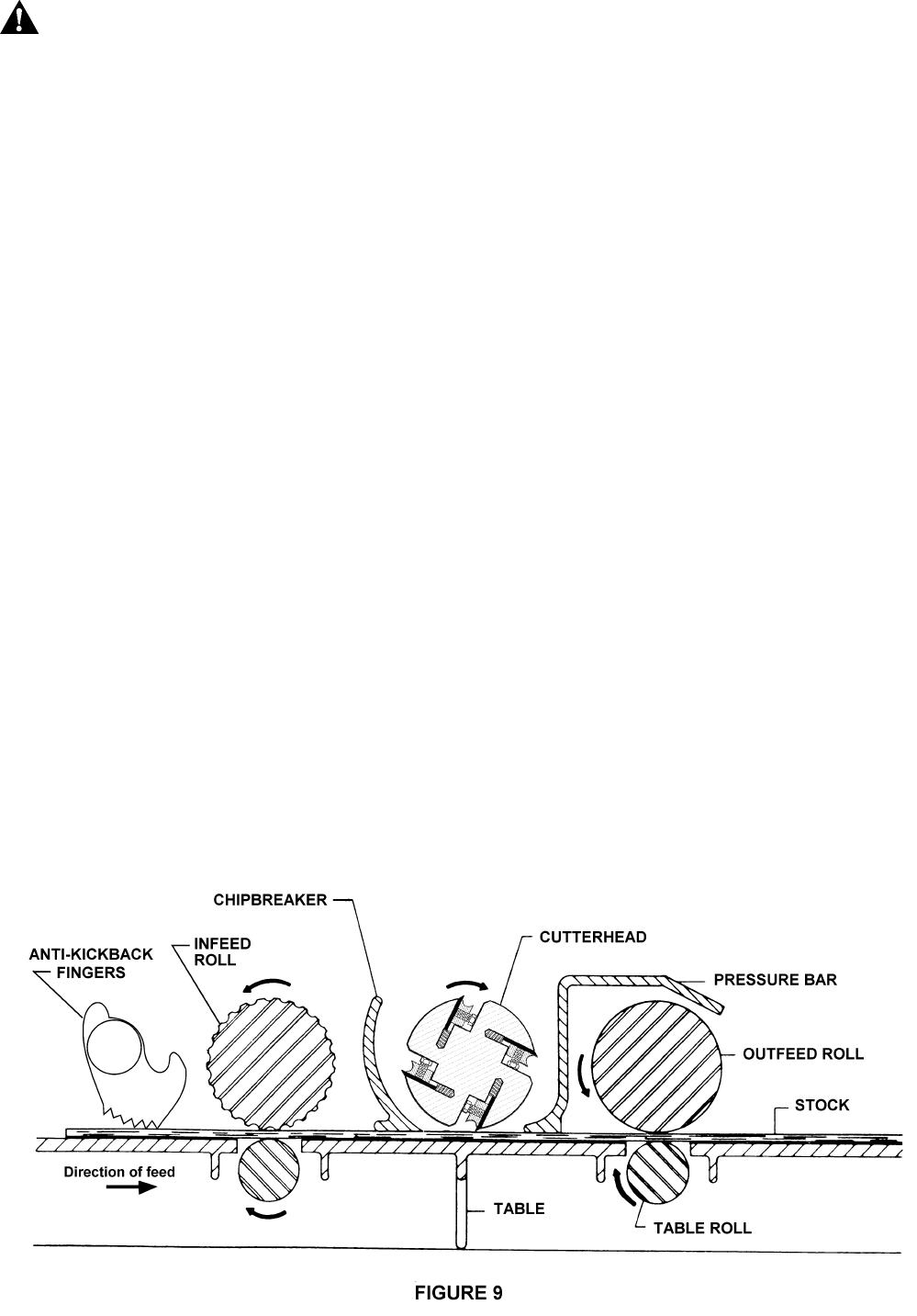

THE FEED SYSTEM OF YOUR PLANER

(Figure 9)

1. Anti-kickback fingers

2. Infeed roll

3. Chipbreaker

4. Cutterhead

5. Pressure bar

6. Outfeed roll

ANTI-KICKBACK FINGERS

Anti-kickback fingers help prevent stock from being

thrown from the machine. These fingers operate by

gravity and should be inspected before each day's use

for pitch or gum buildup. The fingers must operate

freely and move independently for correct operation.

INFEED ROLL

The function of the infeed roll is to feed the material into

the machine. It is a corrugated, sectional roll with

approximately 5/16" independent movement of each

section to accomodate multiple board surfacing.

To provide proper drive, it should be set so that the

bottom of its arc is 1/16" (1.6mm) below the arc of the

cutterhead knives. The infeed roll is under spring

tension and this tension must be sufficient to feed the

stock uniformly through the planer without slipping but

should not be so tight that it causes damage to the

boards. The tension should be equal at both ends of

each roll.