10

Installation of Panel Saw

Uncrating

Remove the panel saw from the shipping container

and check for damage. Report any damage to the

freight company immediately.

A wooden block and three cables have been

fastened to the counterweight to secure it during

shipment. This wooden block and cables must be

removed before operation of the saw. Follow steps

1 through 4:

1. Make sure the cable attached to the motor

carriage is placed over the pulley on top of the

panel saw.

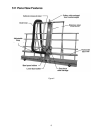

2. Loosen the locking knob on the motor carriage

and move the carriage down to the bottom of

the panel saw. See Figure 3. Tighten the

locking knob securely.

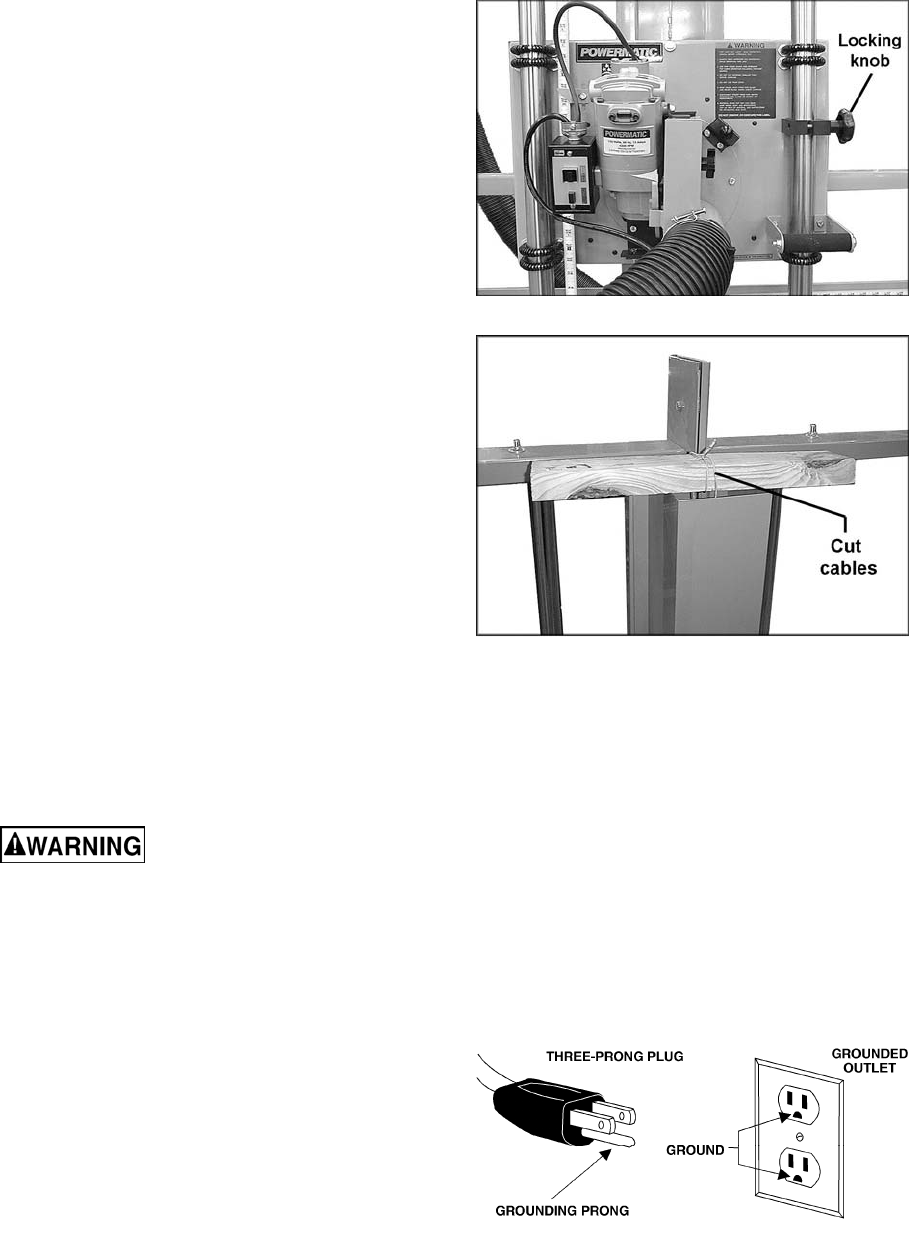

3. At the back of the panel saw, on top of the

counterweight housing, lift up on the wood

block and cut the cables attached to the block.

See Figure 4. DO NOT cut the main cable that

runs through the pulley.

4. Remove the cables and wood block so that the

counterweight can slide freely inside the

housing.

Make sure there is enough space on both sides of

the panel saw for loading, passing, and off-loading

panels.

Grounding Instructions

Improper connection of the

grounding wire can result in electric shock. If

you are unsure whether an outlet is properly

grounded, consult a qualified electrician.

Do not modify the plug provided with the saw and

never remove the grounding prong from the plug. If

cord or plug is damaged, have it repaired before

using the machine. If plug will not fit the outlet,

have a proper outlet installed by a qualified

electrician.

The plug must be connected to a properly

grounded outlet, shown in Figure 5, grounded and

installed in accordance with all codes and

ordinances. If the machine should electrically

malfunction or break down, grounding provides a

path of least-resistance to carry electricity away

from the operator, reducing risk of electric shock.

The grounding prong on the plug is connected

through the green wire inside the cord to the

grounding system in the machine.

The green wire must be the only wire connected to

the machine’s grounding system and must never

be attached to an electrically “live” terminal.

Figure 3

Figure 4

Figure 5