12

2. Feed material through the saw (ripping) or

lower the carriage (crosscutting) slowly,

smoothly and whenever possible without

stopping. Overfeeding can result in poor

quality cuts, shorten the life of the blade, and

overload the motor.

3. Do not drop heavy material onto the rollers, as

this will eventually pound them out of

alignment.

4. For best results, place workpiece onto saw

with its backside facing the operator. This

provides the smoothest cut on the face side of

the panel.

5. Feed workpiece against the rotation of the saw

blade when making horizontal cuts (ripping).

6. Panel saws are for cutting large panels down

to size. As the panel gets smaller, other types

of tools become safer and more convenient to

use.

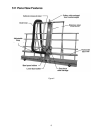

Crosscutting

A crosscut is a vertical cut that is made from the

top to the bottom of the workpiece. See Figure 8.

Do not place hands on or

under the carriage or in path of saw blade.

For safety and accuracy, the workpiece must be

supported on at least two rollers while crosscutting.

See Figure 8.

When the optional Short Panel Fence is used, the

workpiece must extend at least 4" beyond both

sides of the carriage, Figure 9.

Here is the basic procedure for crosscutting:

1. Position the saw motor in the crosscutting

position with the blade oriented vertically.

2. Loosen carriage locking knob and move

carriage to the top of the guides.

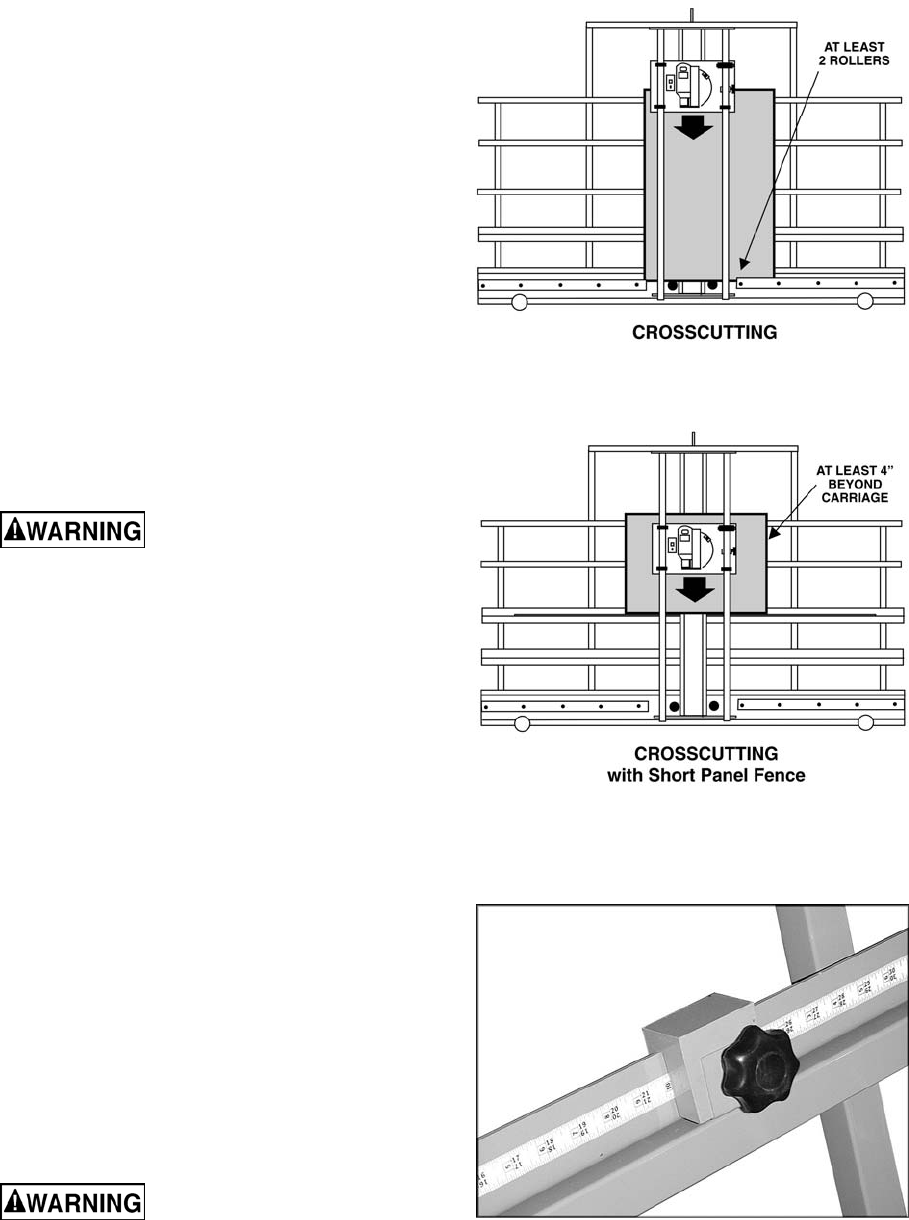

3. Move the adjustable stop (optional accessory

no. 511-ASA), shown in Figure 10, to the

measurement on the horizontal scale (either

left or right side of carriage) that matches the

desired width of your cut.

4. Place the workpiece on top the rollers. DO

NOT DROP it on the rollers.

5. Slide workpiece into position against the

adjustable stop, while double checking the cut

size via the crosscut rulers. Make sure

workpiece is adequately supported. Use one

hand to guide it.

Do not hold workpiece so that

your hand is behind the carriage or guides or

near the path of the blade.

Figure 8

Figure 9

Figure 10