18

Do not use cleaning solvents

such as gasoline, turpentine, lacquer thinner,

paint thinner, or ammonia, as these are harmful

to plastic and some of the insulated parts on

the machine. Never use flammable or

combustible solvents around tools.

Do not immerse the saw in

liquid as this may create risk of injury, electric

shock and damage to the saw.

Periodically:

1. The carriage is designed to move smoothly

along the guide tubes. If the guide tubes

become caked with dust, the carriage may not

slide evenly or become stuck. Occasionally

clean the guide tubes with a damp cloth and

apply a dry lubricant such as a spray silicone.

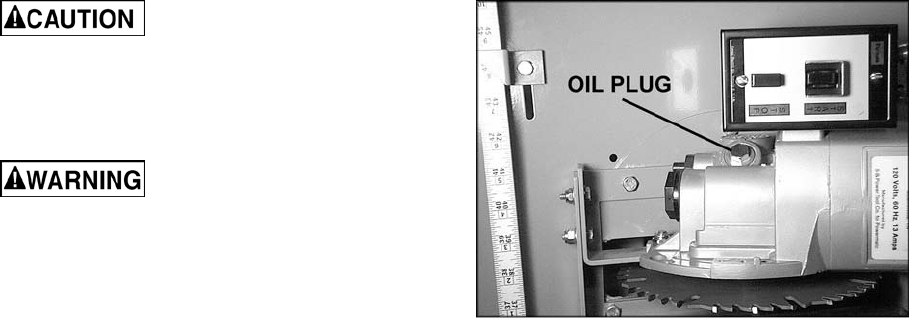

2. Rotate the motor to horizontal position and

check the motor oil level at the plug. Figure 22

shows the location of the oil plug. If low, fill

with SAE 70 or 80 gear oil to proper level. The

gear oil should be changed at least once a

year, or more frequently if the panel saw

receives heavy use.

Every six months:

1. Examine the motor brushes, and replace as

necessary.

2. Inspect and clean gears, spindles, bearings,

housing, etc.

3. Inspect switch, cord, armature, etc.

4. Test to ensure proper mechanical and

electrical performance.

Figure 22

Optional Accessories

511-ASA ....... Adjustable Stop Assembly

Replacement Parts

Replacement parts are listed on the following pages. To order parts or reach our service department, call 1-

800-274-6848, Monday through Friday (see our website for business hours, www.powermatic.com). Having the

Model Number and Serial Number of your machine available when you call will allow us to serve you quickly

and accurately.