13

6. Start motor and allow it to reach full speed.

7. Pull carriage down slowly and smoothly as the

blade moves through the workpiece. Keep

one hand on the handle at all times and do not

force the saw.

NOTE: If the blade binds in the workpiece, or

the workpiece shifts during the cut, stop the

motor, return the carriage to the top of the

guides, restart motor, and then begin the cut

again.

8. Support and remove the cut-off piece as the

saw completes its cut.

9. Once the cut is complete, turn off the motor

and wait for the blade to come to a full stop

(NOTE: A coasting saw blade can mar the

edge of a freshly cut workpiece).

10. Remove the workpieces, return the carriage to

the top of the guides, and lock the carriage.

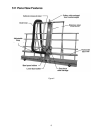

Ripcutting

A ripcut is a horizontal cut made right to left. See

Figure 11. The workpiece must always be moved

in the direction of the arrow on the carriage.

Ripping must be done in

direction of the arrow on saw carriage to

prevent risk of injury.

The minimum length recommended for rip

(horizontal) cuts is 2-1/2 feet, so that the workpiece

can be supported by at least four rollers. (This

measurement also applies when using the optional

Short Panel Fence). Pieces shorter than 4 feet can

be rotated 90 degrees and be crosscut.

Here is the basic procedure for ripcutting:

1. Make sure there is enough space on both

sides of saw to completely load, pass, and

offload the workpiece.

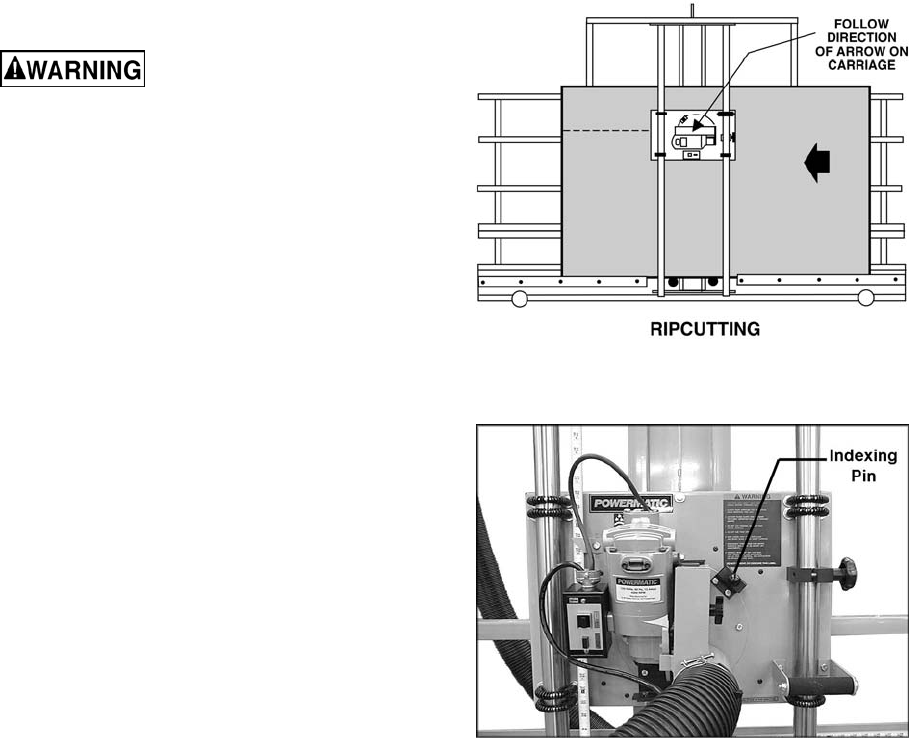

2. Pull indexing pin on turntable (Figure 12), and

rotate turntable counterclockwise. The

indexing pin will lock into place.

3. Select height of saw blade above the rollers.

Move the carriage until the index tab is aligned

with the corresponding dimension on the

vertical ruler. Lock the carriage securely to the

guides with the locking knob.

4. Start motor and allow it to reach full speed.

5. Place workpiece on the side of machine

according to direction of cut shown by the

arrow on the carriage. DO NOT DROP

workpiece on rollers.

6. With the motor at full speed, move the

workpiece slowly and smoothly through the

saw. Do not force the workpiece, as it may

cause binding.

Figure 11

Figure 12