10

Assembly

Tools required for assembly:

Forklift or hoist with straps

10-12mm wrench (provided)

14mm wrench

(NOTE: A socket wrench set may speed assembly

time)

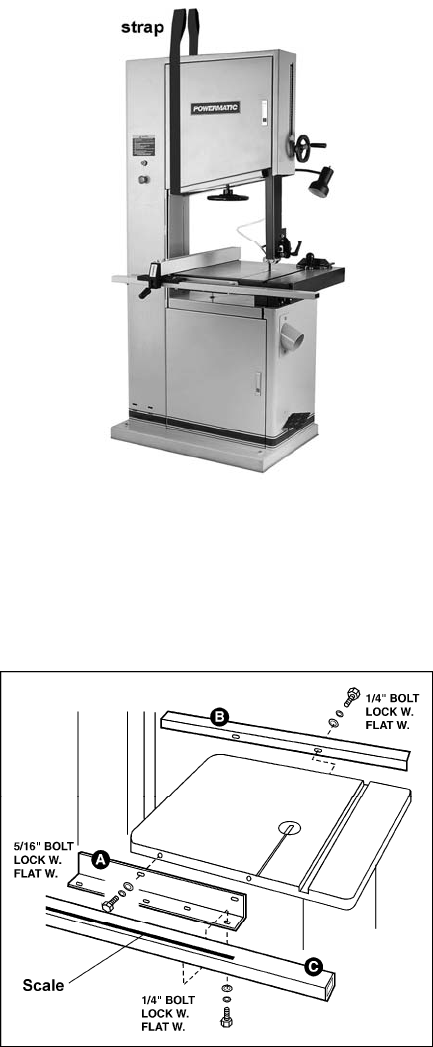

Remove all crating and plastic from around the

band saw. Remove any lag screws or holding

straps which secure the band saw to the wood

pallet.

Use a hoist or forklift with straps to lift the band

saw from the pallet. Position the strap as shown in

Figure 1. (Do NOT place forks or straps directly

under the band saw table to lift it.) Move the band

saw to its permanent location, which should be dry

and well lit, with enough space on all sides to

handle long stock or perform routine maintenance

on the machine. Make sure the floor is able to

support the weight of the machine.

Areas of the Band Saw have been given a

protective coating at the factory. This should be

removed with a soft cloth moistened with kerosene

or mineral spirits. Do not get solvents near plastic

or rubber parts, and do not use an abrasive pad as

it may scratch metal surfaces.

Installing Fence and Rails

1. Mount the front rail (A, Figure 1a) to the saw

table with two 5/16 x 1-1/4 hex cap screws,

two 5/16 lock washers, and two 5/16 flat

washers. Screws should be placed horizontally

in approximately the center of the slot. Hand

tighten the screws.

2. Mount the rear rail (B, Figure 1a) to the table

with two 1/4 x 5/8 hex cap screws, two 1/4 lock

washers, and two 1/4 flat washers. Hand

tighten the screws.

3. Push the front and rear rails upward (toward

the table top) as far as they will go.

4. Tighten the two hex cap screws holding the

front rail to the table, with a 12mm wrench.

Tighten the two hex cap screws holding the

rear rail to the table with a 10mm wrench.

5. Attach the guide rail (C, Figure 1a) to the front

rail with five 1/4 x 5/8 hex cap screws, five 1/4

lock washers, and five 1/4 flat washers. The

scale on the guide rail should face toward the

operator. Hand tighten the screws only.

Figure 1

Figure 1a