24

If replacement of the blade is not currently an

option, the blade lead can be compensated for by

skewing the fence. Proceed as follows:

1. Cut a scrap piece of wood about the same

length as the band saw table, and joint one

edge along its length, or rip it on a table saw to

give it a straight edge.

2. Draw a line on the board parallel with the

jointed, or straight edge of the board.

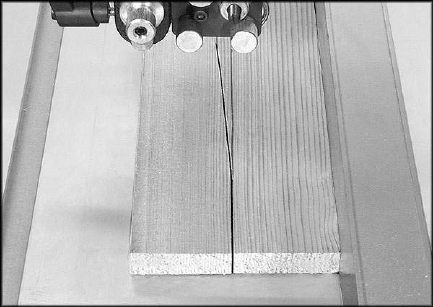

3. Move the band saw fence out of the way, and

carefully make a freehand cut along your

drawn line on the board. Stop about midway

on the board, and shut off the band saw (allow

the blade to come to a complete stop) but do

not allow the board to move.

4. Clamp the board to the table.

5. Slide the band saw fence over against the

board until it contacts the straight edge of the

board at some point. Lock the fence down.

6. Loosen the four hex cap screws at the top of

the fence (see Figure 3) and shift the fence

until it is parallel to the board along its length.

7. Re-tighten the four hex cap screws.

NOTE: Skewing the fence to correct blade lead is

effective for that particular blade; when a new

blade is installed, the fence will probably need re-

adjustment.

Blade Selection

Using the proper blade for the job will increase the

operating efficiency of your band saw, help reduce

necessary saw maintenance, and improve your

productivity. Thus, it is important to follow certain

guidelines when selecting a blade.

Here are factors to consider when selecting a

blade:

• The type of material you will be cutting.

• The thickness of the workpiece.

• The features of the workpiece, such as bends

or curves with small radii.

These factors are important because they involve

basic concepts of saw blade design. There are five

(5) blade features that are normally changed to

meet certain kinds of sawing requirements. They

are:

1. width

2. pitch (number of teeth per inch)

3. tooth form (or shape)

4. the “set” of the teeth

5. the blade material itself

Figure 34