27

Maintenance

Before doing maintenance,

disconnect machine from electrical supply by

pulling out the plug or switching off the main

switch! Failure to comply may cause serious

injury.

Clean the band saw regularly to remove any

resinous deposits and sawdust. Keep the miter slot

in the table free of dust and debris. Keep the guide

bearings clean and free of resin.

Grease the rack and pinion system of the guide

bar.

Oil any pins, shafts, and joints. Do not get oil on

the pulleys or belts.

Bearings on the band saw are sealed for life and

do not require lubrication.

Check that the cleaning brush over the lower wheel

is working properly; adjust if necessary.

Remove any deposits from the band wheels to

avoid vibration and blade breakage.

The table surface must be kept clean and free of

rust for best results. If rust appears, use a mixture

of household ammonia, a good commercial

detergent and 000 steel wool. (Alternatively,

commercial rust removers can be found at many

hardware stores.) Then wash table down with hot,

soapy water, rinse and dry thoroughly.

Apply a light coat of paste wax to the table. Or,

some users prefer talcum powder applied with a

blackboard eraser rubbed in vigorously once a

week; this will fill casting pores and form a moisture

barrier. This method provides a table top that is

slick and allows rust rings to be easily wiped from

the surface. Important also is the fact that talcum

powder will not stain wood or mar finishes as wax

pickup can.

If the power cord is worn, cut, or damaged in any

way, have it replaced immediately.

Tire Replacement

1. Disconnect machine from power source.

2. Remove the blade from the machine.

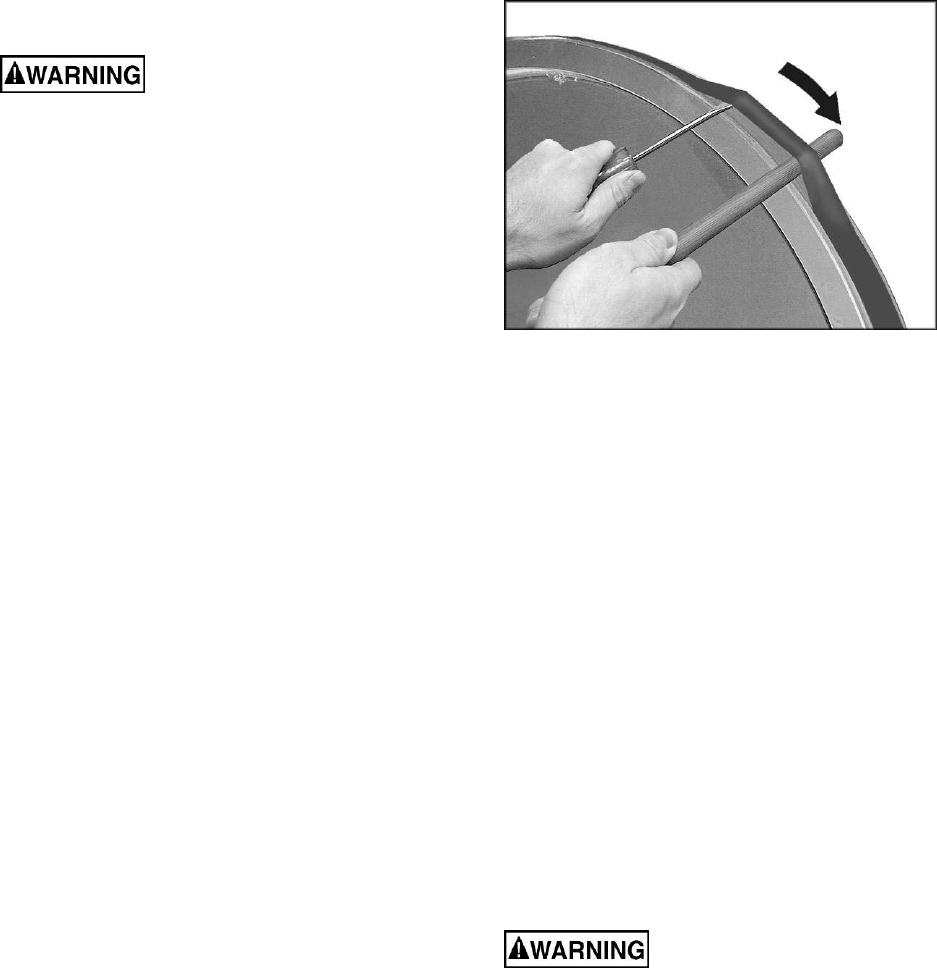

3. Insert a flat head screwdriver beneath the lip of

the tire. Pry up the tire and pull it off the wheel.

If this proves difficult, insert a wood wedge or

dowel into the opening (see Figure 38), and

continue to pry around the perimeter of the

wheel until the tire comes off the wheel.

Figure 38

4. Clean the rim of the band wheel before

installing the new tire.

5. The new tire can be installed without removing

the band wheel from the machine; or, you can

remove the band wheel (see “Band Wheel

Replacement” for removal instructions) and

place it on a workbench, using a home-made

jig to secure it while installing the new tire.

6. Place part of the new tire over the band wheel

and work it onto the rim of the band wheel. If

needed, insert a wood dowel beneath the tire

and move the dowel around the perimeter of

the band wheel to guide the tire on.

NOTE: Although the tire may look too small, it

will stretch around the band wheel with the

proper exertion, and will form a tight fit. Unlike

rubber tires for many older model band saws,

the tires for the 2013 and 2415 will not require

trimming, equalizing, etc., nor do they require

an adhesive. Rather, they are ready to use

immediately after installation.

Band Wheel Replacement

The cast iron band wheels are

heavy; use care when removing them.

Disconnect machine from power, and remove the

blade. Loosen and remove the hex nut and flat

washer at the wheel’s hub. Carefully pull off the

wheel by hand or with a “wheel puller.”