10

ASSEMBLY

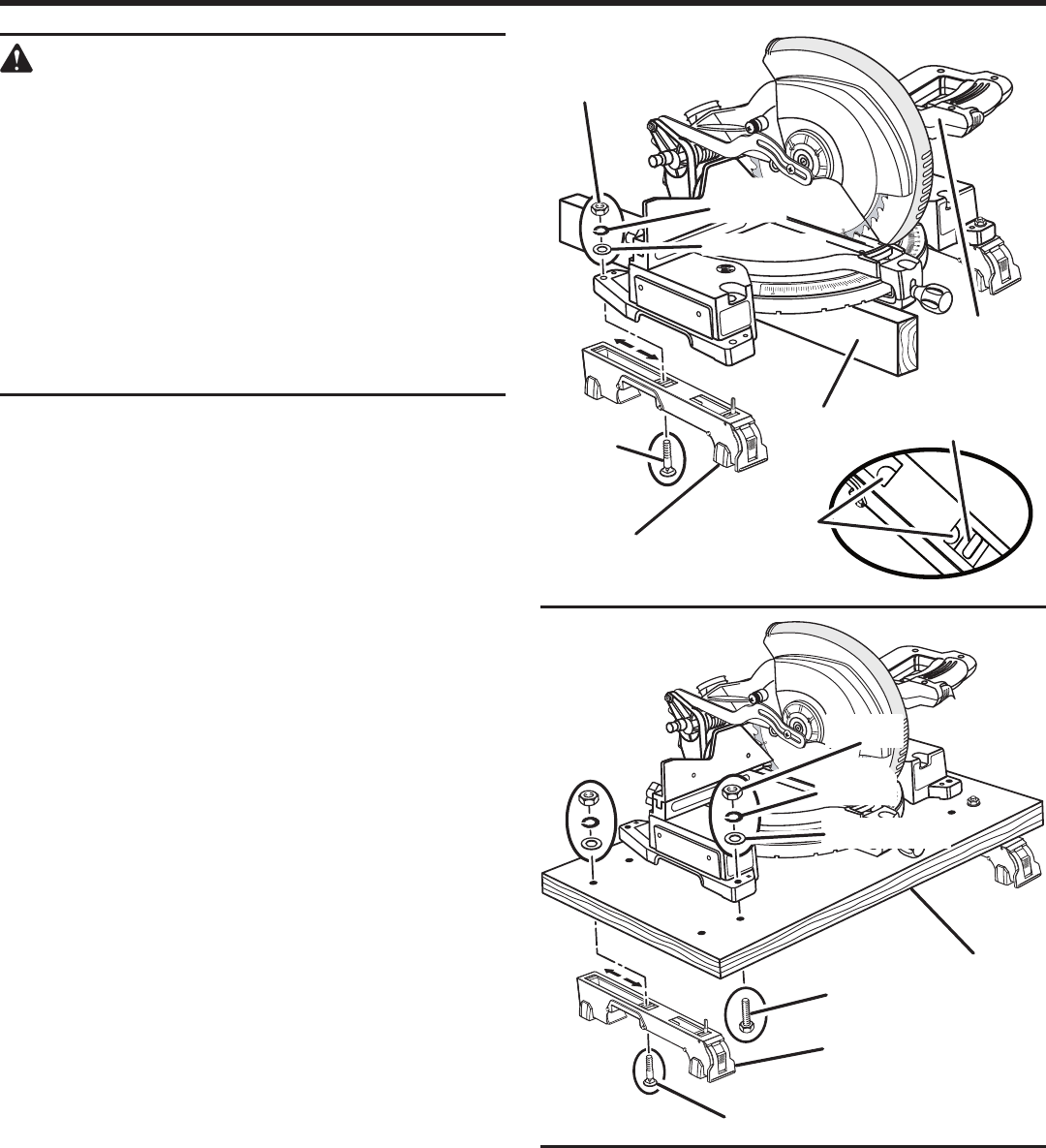

WARNING:

The saw mounting brackets are designed to fit

snugly over the table edges with locking levers in

the open position. With the locking levers in the

lowered (locked) position, you should not be able

to slide the saw mounting bracket assembly along

the table edges or remove the bracket assembly

from the table edges. If the saw mounting brackets

will not fit over the edges, or if the brackets can

be removed from the edges when the levers are

locked, remove bracket assembly immediately

and adjust bracket adjustment screw. See the

Maintenance section of this manual. Failure to heed

this warning may result in serious personal injury.

ATTACHING SAW TO THE MOUNTING

BRACKETS

See Figures 11 - 12.

Always position the saw to achieve maximum balance and

stability. All four corners of the saw must be bolted to the

mounting brackets before use. Make sure bolts do not

extend above the table of the miter saw.

NOTE: Four additional 1-1/2 in. bolts have been provided

for use when securing a sliding miter saw to the mounting

brackets.

NOTE: Ensure that mounting brackets can be clamped

securely onto stand before mounting saw. If locking lever on

saw mounting bracket cannot easily be pushed down into

the closed position, the adjustment screw is too tight. Do

not force locking lever into the closed position. Loosen the

adjustment screw. Refer to the Maintenance section later in

this manual for mounting bracket adjustment.

If the saw has mounting holes that line up with the slots

in the saw mounting brackets:

Disconnect the saw from power supply and lock the saw

arm in the down position.

Place a 2 x 4 or similar type of stable support underneath

the saw to raise the saw and allow access to the saw’s

mounting feet.

Feed a carriage bolt up through each side of the bracket

and adjustment plate.

Align bolts in the two sliding adjustment plates on the

saw mounting bracket with the saw mounting holes.

Place the saw mounting bracket underneath the raised

side of the saw, and insert bolts through mounting holes

in saw.

Loosely secure in place using a flat washer, lock washer,

and hex nut.

Repeat procedure to attach second bracket to saw.

After making sure both brackets are parallel to each other,

lightly tighten all four nuts to hold in position.

If the saw has holes that do not line up with the sliding

adjustment plates in the saw mounting brackets:

Fig. 12

15

20

25

30

35

40

45

10

HEX BOLT

CARRIAGE BOLT

MOUNTING

SURFACE

HEX NUT

FLAT WASHER

LOCK

WASHER

SAW

MOUNTING

BRACKET

Disconnect the saw from power supply and lock saw arm

in the down position.

Mount the saw to a mounting surface at least 1/2 in.

thick using 5/16 hex head bolts, washers, and nuts (not

included).

Drill holes in the mounting surface to match the sliding

adjustment plates in the saw mounting brackets.

Proceed with installation as previously described.

15

20

25

30

35

40

45

10

CARRIAGE

BOLT

SAW

MOUNTING BRACKET

HEX NUT

STABLE

SUPPORT

SLIDING

ADJUSTMENT

PLATE

Fig. 11

FLAT WASHER

SAW ARM

CARRIAGE BOLT

LOADING SLOTS

LOCK

WASHER