7

Changing Motor Voltage

WARNING: If not properly grounded, this tool can

cause an electrical shock, particularly when used in

damp locations, in proximity to plumbing, or out of

doors. If an electrical shock occurs there is the poten-

tial of a secondary hazard, such as your hands con-

tacting the knives.

NOTE: The band saw is prewired at the factory for 120V

operation. Use the following procedure to change motor

voltage. To change to 240V application an additional wire

nut is supplied from the factory. This part is included in

the loose parts.

1. Unplug the band saw before making or changing any

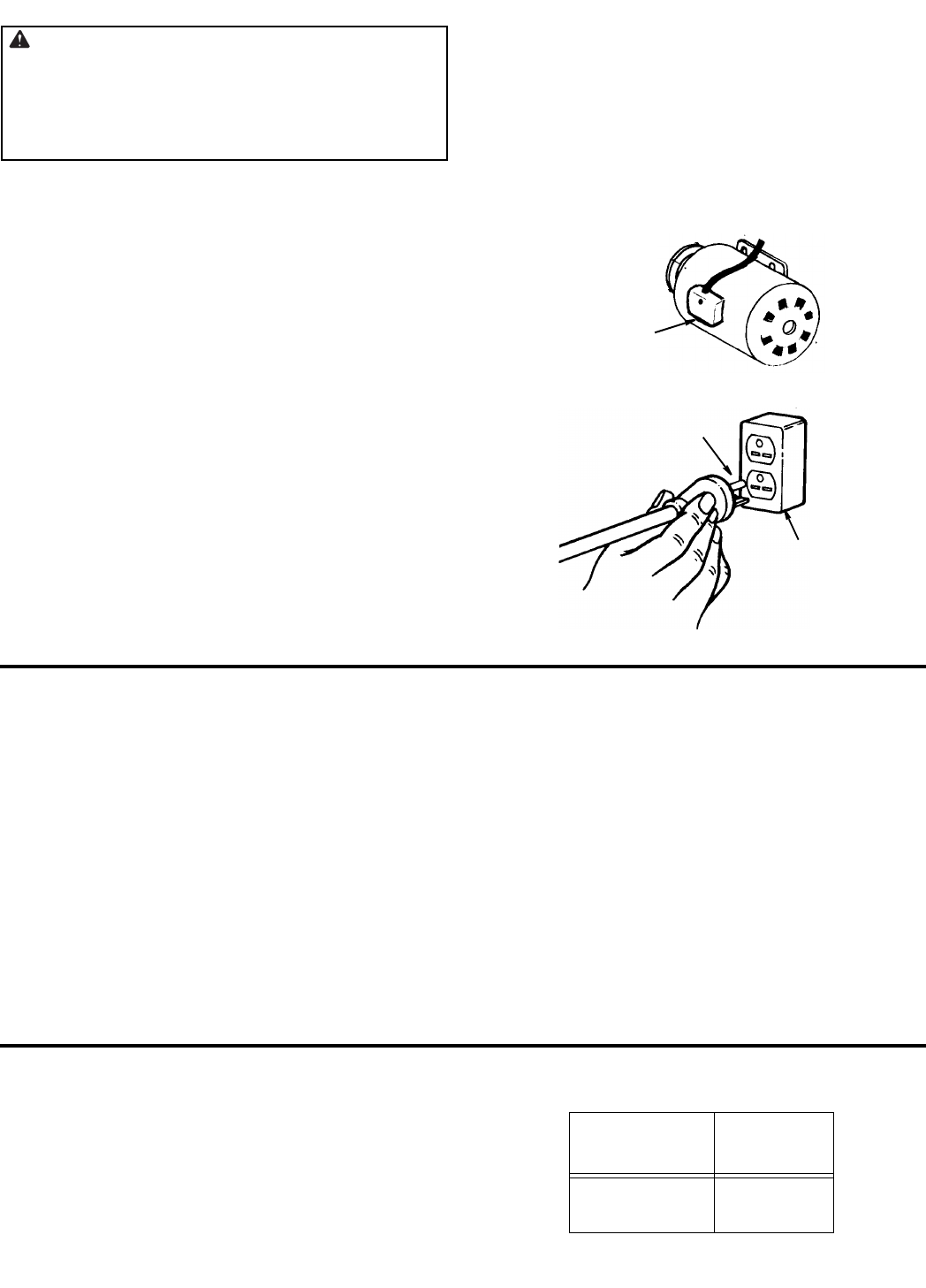

connections. Open the motor junction box cover

located on the side of the motor.

2. Remove and discard the electrical tape from the wire

nuts. Remove wire nuts.

3. Reconnect the leads as shown in the “Wiring Diagram”

section at the rear of manual.

4. Reinstall the wire nuts and wrap with two layers of new

U.L. listed electrical tape per wire nut.

5. Recheck your wiring to the wiring diagrams. Do this so

you can be sure that the wiring is correct.

6. Reinstall the junction box cover.

7. Cut off the 120 volt power cord plug and replace it with

a (3 blade) 240 volt 15 amp U.L. Listed Assembled - on

Plug Cap suitable for 16 AWG Type SJT Cord. (See

illustration of 240V plug & receptacle.) Connect the

power cord white and black leads, respectively, to the

“hot” plug blade terminals and connect the power cord

green grounding wire to the plug ground prong termi-

nal.

8. Plug your band saw into a 220-240V, 15 amp, 3 blade

receptacle.

9. Make certain the receptacle is connected to a 240 volt

A.C. power supply through a 240 volt branch circuit

having at least a 15 amp capacity and protected by a

15 amp time-delay fuse or circuit breaker.

220-240 Volt, 60 Hz. Tool Connections

Motor Safety Protection

1. Connect this tool to a power source with the appropri-

ate voltage for your model and a 15-amp branch circuit

with a 15-amp time delay fuse or circuit breaker. Using

the wrong size fuse can damage the motor.

2. If the motor won't start, turn off the power switch imme-

diately and unplug the tool. Check the saw blade to

make sure it turns freely. If the blade is free, try to start

the motor again. If the motor still does not start, refer to

the "Motor Troubleshooting Chart."

3. If the motor suddenly stalls while cutting wood, turn off

the power switch, unplug the tool and free the blade

from the wood. The motor may now be restarted and

the cut finished.

4. Fuses may "blow" or circuit breakers may trip fre-

quently if:

a. Motor Is Overloaded-Overloading can occur if you

feed too rapidly or make too many start/stops in a

short time.

b. Line voltages should not be more than 10% above

or below the nameplate voltage. For heavy loads,

however, the voltage at motor terminals must equal

the voltage specified for your model.

c. Improper or dull saw blade is used.

5. Most motor troubles may be traced to loose or incor-

rect connections, overload, low voltage (such as small

size wire in the supply circuit) or to overly long supply

circuit wire. Always check the connections, the load

and the supply circuit whenever motor doesn't work

well. Check wire sizes and length with the Wire Size

Chart.

Wire Sizes

NOTE: Make sure the proper extension cord is used and

is in good condition.

The use of any extension cord will cause some loss of

power. To keep this to a minimum and to prevent overheat-

ing and motor burnout, use the table shown to determine

the minimum wire size (A.W.G.) extension cord.

Use only 3-wire extension cords which have 3-prong

grounding type plugs and 3-pole receptacles which

accept the tools plug.

Junction

Box Cover

Grounding

Prong

Grounded

Outlet Box

Extension

Cord Length

Gauge

(A.W.G.)

0-25 Ft.

26-50 Ft.

14

12