Page 10

ADJUSTMENTS

WARNING:

To prevent accidental starting that could cause possible

serious personal injury, assemble all parts to your cut-off

machine before connecting it to power supply. Machine

should never be connected to power supply when you

are assembling parts, making adjustments, installing or

removing wheels, or when not in use.

As mentioned previously your cut-off machine has been

factory assembled and adjusted. After extended use and

wear, the wheel will need to be replaced with a new one.

WARNING:

A 14 in. (356 mm) wheel is the maximum wheel capacity

of your cut-off machine. Never use a wheel that is too

thick to allow outer flange to engage with the flats on the

spindle. Larger wheels will come in contact with the wheel

guards, while thicker wheels will prevent the bolt from

securing the wheel on the spindle. Either of these

situations could result in a serious accident and can cause

serious personal injury.

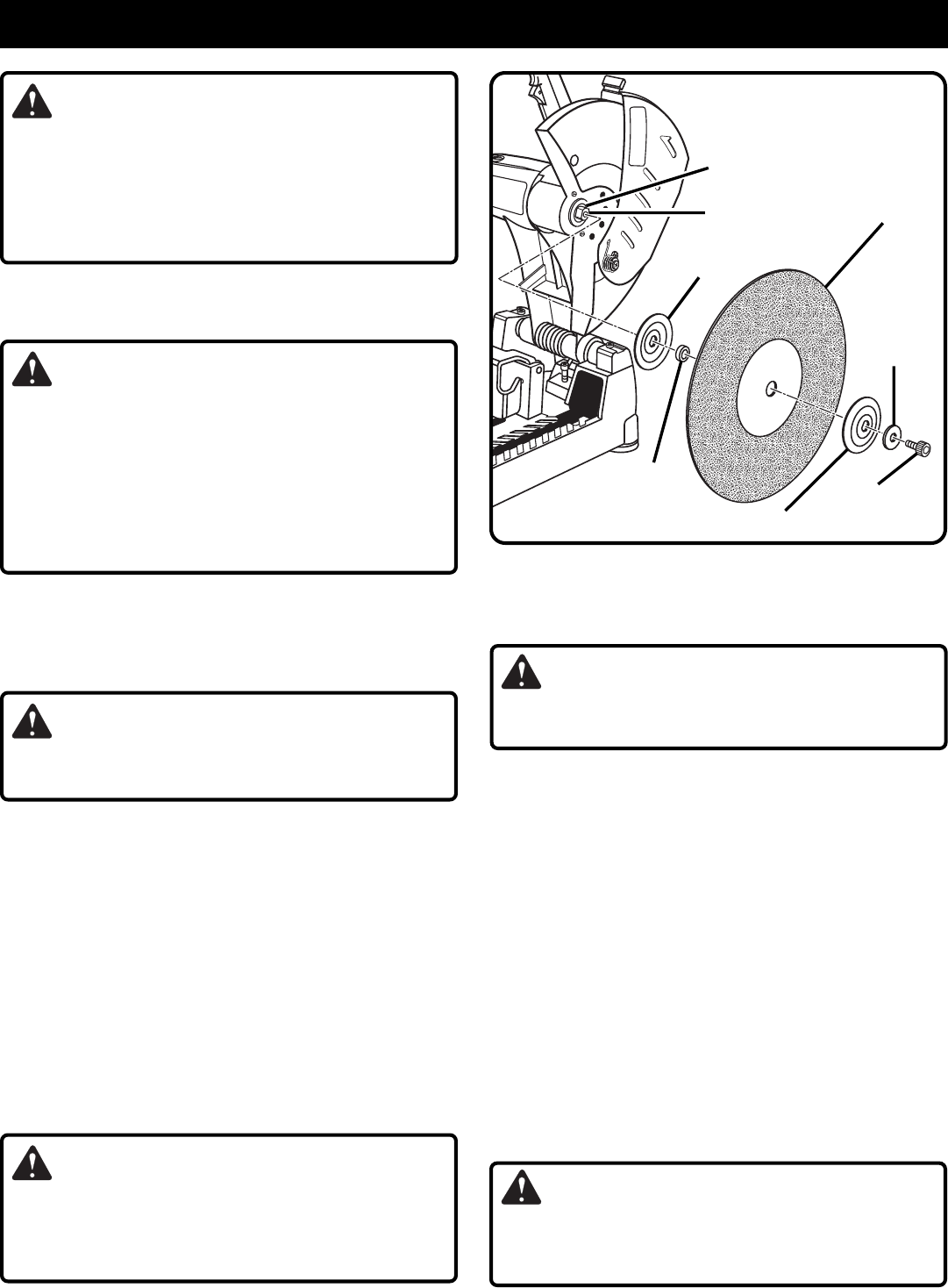

REMOVAL AND INSTALLATION OF WHEEL

TO REMOVE

See Figure 5.

■ Unplug your cut-off machine.

WARNING:

Failure to unplug cut-off machine could result in accidental

starting causing possible serious personal injury.

■ Push down on machine arm and pull out arm lock lever

to release machine arm.

■ Raise machine arm to its full raised position. Be cautious

when raising, machine arm is spring loaded.

■ Rotate lower wheel guard upward, exposing 8 mm socket

head bolt that secures abrasive wheel to wheel arbor.

■ Depress the spindle lock button and rotate bolt until

spindle locks, preventing shaft from rotating.

■ Using the 8 mm hex key provided, loosen and remove

bolt. Note: Bolt has right hand threads. Turn bolt

counterclockwise to loosen.

■ Remove outer washer, outer flange, spacer, and wheel.

Do not remove inner flange or inner washer. Removal of

these two parts are not required for wheel changes.

WARNING:

If inner flange or inner washer has been removed, replace

both before placing wheel on spacer and wheel arbor.

Failure to do so could cause an accident since wheel will

not tighten properly.

TO INSTALL

See Figure 5.

■ Unplug your cut-off machine.

WARNING:

Failure to unplug cut-off machine could result in accidental

starting causing possible serious personal injury.

■ Inspect the replacement wheel for defects such as cracks,

chipping, and correct speed rating. If defects are found

or the speed rating is not greater than 3300 rpm, do not

use. Select another wheel.

■ Clean debris from the inner washer and inner flange.

■ Place new wheel over spacer, then place both on wheel

arbor against inner flange.

■ Clean outer flange, then align flats with flats on wheel

arbor and slide it onto arbor until it is flush against wheel.

■ Place recessed side of outer washer against arbor, then

insert socket head bolt into threaded end of wheel arbor.

■ Start threads and turn bolt clockwise to snugly tighten.

■ Depress the spindle lock button and rotate bolt until

spindle locks, preventing shaft from rotating.

■ Using the 8 mm hex key provided, securely tighten socket

head bolt. Note: Bolt has right hand threads. Turn bolt

clockwise to tighten.

WARNING:

Do not overtighten socket head bolt. Overtightening can

cause the new wheel to crack, resulting in premature

failure and possible serious personal injury.

Fig. 5

OUTER

WASHER

OUTER FLANGE

14 in. (356 mm)

ABRASIVE

WHEEL

SPACER

INNER

FLANGE

WHEEL BOLT

WHEEL ARBOR

INNER

WASHER