Page 15

15

45

0

OPERATION

CUT-OFF

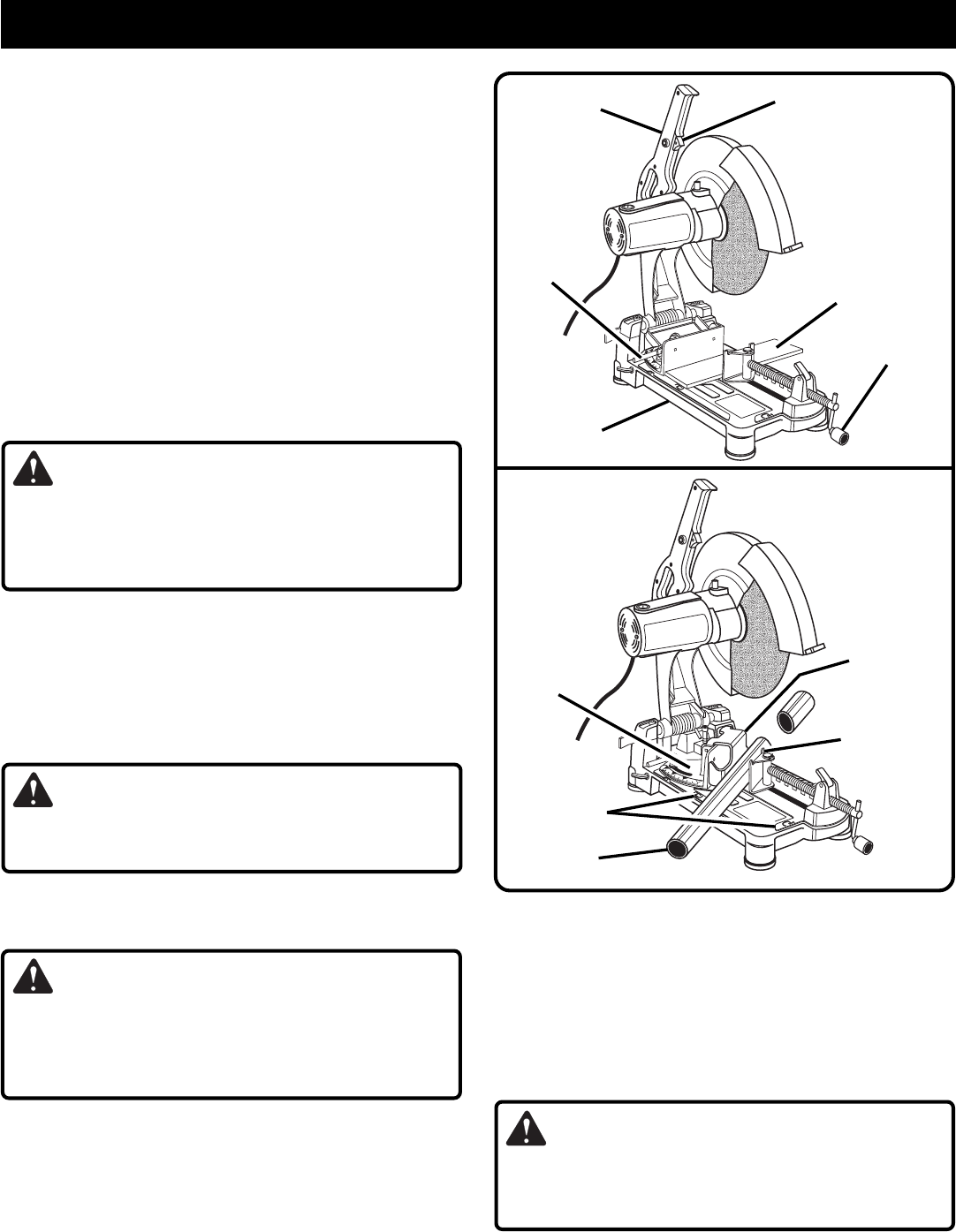

See Figures 14 and 15.

A cut-off is made by cutting across the width of the

workpiece. A straight crosscut is made with the adjustable

flip fence set at the zero degree position. Angled cut-offs

are made with the adjustable flip fence set at some angle

other than zero.

To cut with your cut-off machine:

■ Firmly secure the material to be cut using the machine’s

vise (adjustable flip fence, extension block, and vise

clamp).

■ Using the fence lock handle, loosen the fence assembly.

See Figures 14 and 15.

■ Rotate the adjustable fence to the angle needed.

■ Retighten fence lock handle.

WARNING:

To avoid serious personal injury, always tighten fence

lock handle securely before making a cut. Failure to do

so could result in movement of the workpiece while

making a cut.

■ Place the workpiece flat on the machine base with one

surface securely against the adjustable flip fence.

■ Align cutting line on the workpiece with the edge of the

abrasive wheel.

■ Push in the vise crank handle to set the vise clamp against

the workpiece. Turn the vise crank handle 1/2 to 1 turn

clockwise to securely clamp the workpiece to the fence.

WARNING:

To avoid serious personal injury, keep your hands at least

3 in. (76.2 mm) from wheel.

■ When cutting long pieces, support the opposite end of

the material with a roller stand or with a work surface

level with the machine base.

WARNING:

Never perform any cutting operation freehand (without

placing workpiece in the vise). Material will get hot during

cutting operation. Keep hands off of metal being cut to

avoid serious personal injury.

■ Before turning on machine, perform a dry run of the cutting

operation just to make sure that no problems will occur

when the cut is made.

■ Start the machine by grasping the handle and fully

squeezing the switch trigger. Allow several seconds for

the wheel to build up to full speed before letting it come

into contact with the material to be cut.

Fig. 14

Fig. 15

MACHINE

BASE

MACHINE ARM

(HANDLE)

SWITCH

TRIGGER

MATERIAL

TO BE CUT

EXTENSION

BLOCK

ADJUSTABLE

FLIP FENCE

VISE

CLAMP

0

15

30

45

FENCE

LOCK

HANDLE

MATERIAL

TO BE CUT

“C” CLAMP

AREA

VISE

CRANK

HANDLE

■ Once it reaches full speed slowly lower the handle of the

machine arm until the cut-off wheel comes in contact with

the material being cut. Continue to use steady and even

pressure to obtain a uniform cut through the workpiece.

Never force the wheel into the material being cut.

■ When the cut is complete, release the switch trigger and

allow the wheel to stop rotating before raising the wheel

out of workpiece.

WARNING:

Do not touch the cut material until it cools or you can be

burned. Failure to heed this warning could result in serious

personal injury.