Page 9

0

15

30

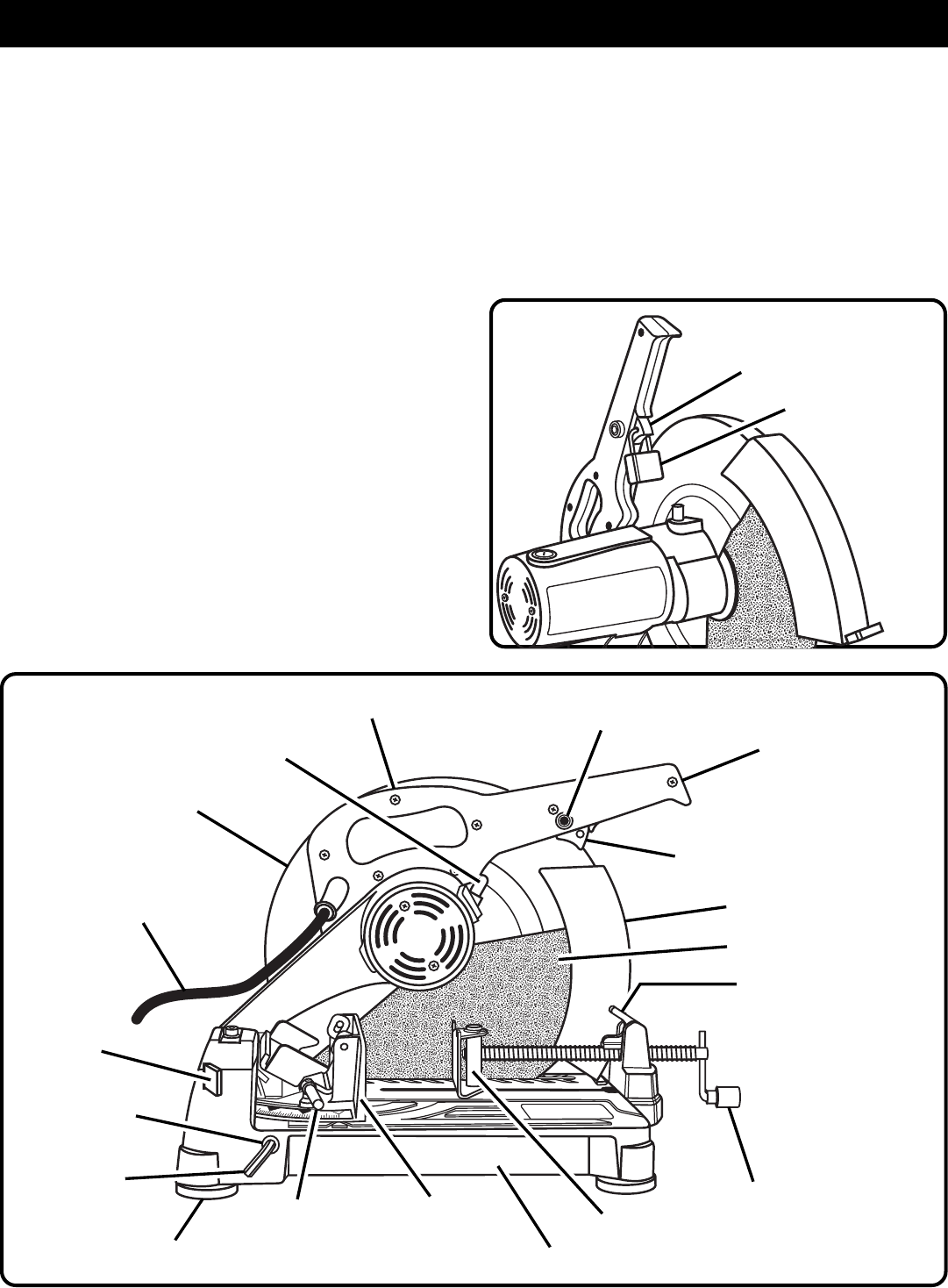

Fig. 3

LOWER

WHEEL GUARD

UPPER

WHEEL GUARD

MACHINE ARM

LOCK-ON

BUTTON

RUBBER FEET

CARRYING HANDLE

MACHINE BASE

SWITCH TRIGGER

VISE CLAMP

POWER CORD

QUICK LOCK-

RELEASE LEVER

VISE CRANK

HANDLE

8 mm

HEX KEY

WRENCH

STORAGE

ADJUSTABLE

FLIP FENCE

ASSEMBLY

Fig. 4

PADLOCK

SWITCH TRIGGER

14 in. (356 mm)

ABRASIVE WHEEL

ARM

LOCK

LEVER

FEATURES

CARRYING HANDLE

See Figure 3.

For convenience when carrying or transporting your cut-off

machine from one place to another, a carrying handle has

been provided on top of the machine arm as shown figure 3.

To transport, turn off and unplug your machine, then lower

machine arm and lock it in the down position. Lock machine

arm by pushing in arm lock lever.

LOCK-ON BUTTON

See Figure 3.

Your cut-off machine is equipped with a lock-on feature,

which is convenient when continuous cutting for extended

periods of time is required. To engage the lock-on feature,

depress switch trigger, push in and hold the lock-on button

located on the side of the handle, then release switch trigger.

Release lock-on button and machine will continue running.

To release lock-on feature, depress switch trigger and release.

If you have the lock-on feature engaged during use and your

machine becomes disconnected from power supply,

disengage the lock-on feature immediately.

SPINDLE LOCK BUTTON

A spindle lock button has been provided for locking the

spindle which keeps the wheel in your machine from rotating.

Depress and hold the spindle lock button while installing,

changing, or removing wheel only.

TRIGGER LOCK

See Figure 4.

To prevent unauthorized use of your cut-off machine, we

suggest that you disconnect it from the power supply and

lock the switch in the off position. To lock the switch, install

a padlock (not included) through the hole in the switch

trigger. A lock with a shackle up to 13/64 in. diameter may be

used. When the lock is installed and locked, the switch is

inoperable. Store the padlock key in another location.

SPINDLE

LOCK BUTTON

FENCE

LOCK HANDLE