Page 13

ADJUSTMENTS

WARNING:

Failure to turn the saw off, remove the switch key, and

unplug the saw could result in accidental starting causing

possible serious personal injury.

WARNING:

Failure to turn the saw off, remove the switch key, and

unplug the saw could result in accidental starting causing

possible serious personal injury.

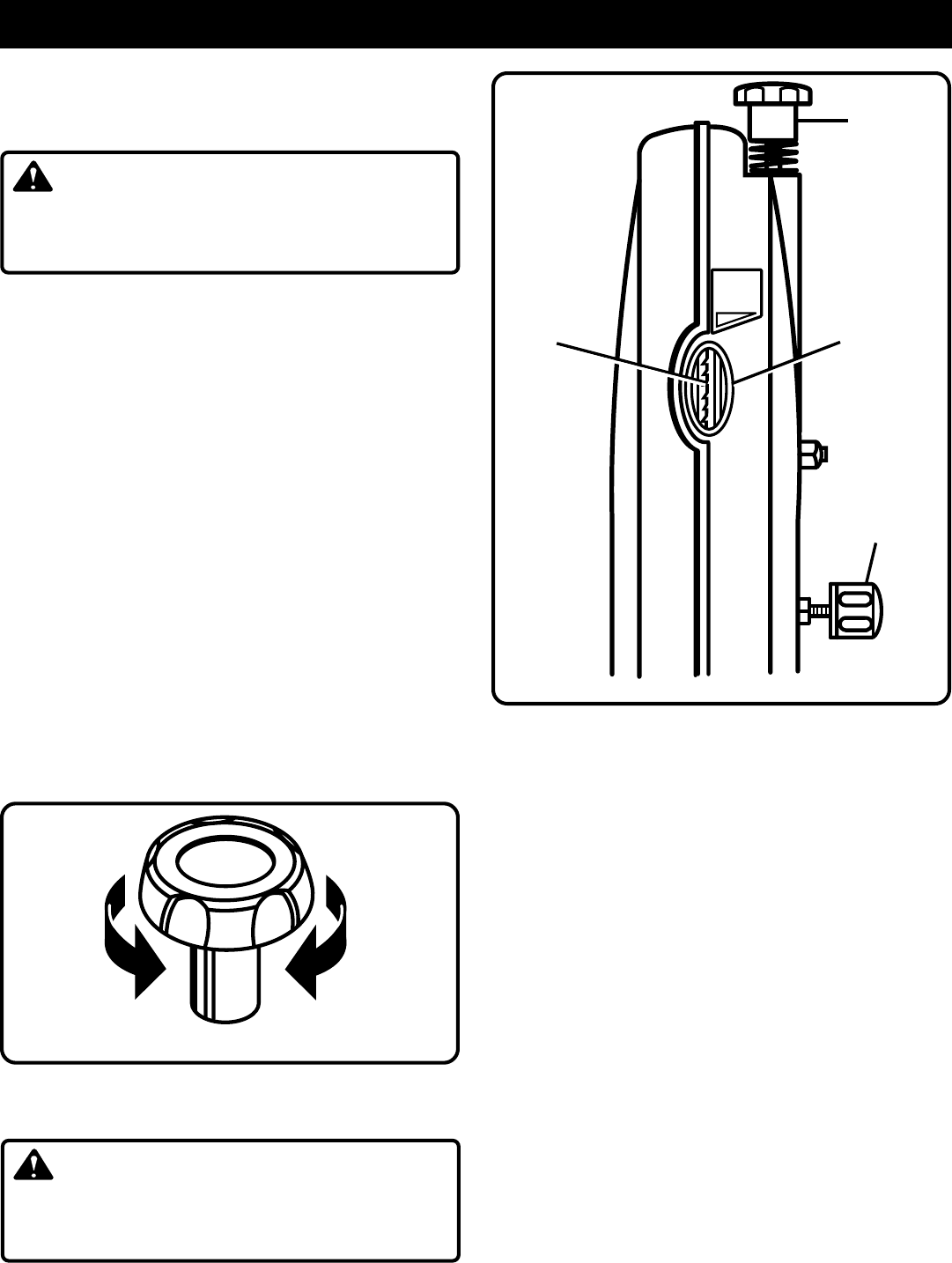

ADJUSTING BLADE TENSION

See Figures 10 and 11.

■ Turn off and unplug the saw. Remove the switch key.

■ Before using the band saw, turn the blade tension knob

on the top of the saw clockwise to engage tension.

See

Figure 10.

■ To check tension, raise the blade guide assembly all the

way up to expose the blade.

■ Push the blade to the side with moderate force; the blade

should flex approximately 1/8 in. (3 mm).

Note: Adjustments of blade tension can be made at any-

time.

Another method of checking blade tension has to do with the

sound the blade makes when plucked like a guitar string.

■ Pluck the back straight edge on the coasting side opposite

the blade guides while turning the tension knob. Sound

should be a musical note. Sound becomes higher pitched

as tension increases.

Using either method to check blade tension can be developed

with practice.

■ Never increase blade tension so tight as to completely

compress the spring. When completely compressed, the

spring can no longer act as a shock absorber.

Note: Too much tension may cause the blade to break. Too

little tension may cause the blade to slip on the wheels.

TRACKING THE BLADE

See Figure 11.

Note: Adjust blade tension properly before making tracking

adjustments. Check that the blade guides are not interfering

with the blade.

To Adjust:

■ Open the front cover by releasing the upper and lower

latches. Watch the blade’s position on the upper tire

through the tracking view window as, by hand, you slowly

turn the upper wheel clockwise. If the blade moves away

from the center of the tire, the tracking must be adjusted

.

If the blade has moved left or right of center:

■ Turn the blade tracking knob (clockwise if blade has

moved left and counterclockwise if blade has moved right)

while turning the wheel by hand until the blade moves

back and rides in the center of the tire

.

■ Check the position of the blade on the lower tire. The

blade should be completely on the tire. If not, adjust the

tracking until the blade is on both tires.

■ Rotate the upper wheel by hand in a clockwise direction

for a few more turns. Make sure the blade stays in the

same location on the tires. Readjust, if necessary, until

blade is tracking properly.

■ Close front cover and relatch.

Note: The 1/8 in. (3 mm) blade may not track properly in the

center of the wheel. It may be better to track this blade on

the back half of the upper wheel.

Fig. 11

Tracking

View

Window

BLADE ON

WHEEL

BLADE

TENSION

KNOB

BLADE TRACKING

KNOB

TRACKING

VIEW

WINDOW

TO DECREASE

TENSION

Fig. 10

BLADE TENSION KNOB

TO INCREASE

TENSION