Page 14

ADJUSTMENTS

■ Remove the blade guard by loosening the two set screws

with the 4 mm hex key.

■ Turn the lock lever counterclockwise to unlock the blade

guide assembly. Turning the blade guide knob clockwise,

raise the blade guide assembly as far as it will go.

Retighten the blade guide knob.

■ Place a small combination square on the saw table beside

the blade.

■ Loosen the table lock handle and rotate the angle

adjustment knob to tilt the saw table up or down to align

table 90° to blade (0° position). Retighten the table lock

handle.

■ Using an adjustable wrench, adjust the zero stop set

screw until the set screw just touches the saw housing.

■ Check squareness of the saw table to the blade. Make

readjustments if necessary.

■ Loosen screw on scale indicator with a phillips screwdriver

and align scale indicator to zero.

■ Tighten all screws securely.

■ Replace the blade guard once the saw table has been

squared.

WARNING:

Failure to turn the saw off, remove the switch key, and

unplug the saw could result in accidental starting causing

possible serious personal injury.

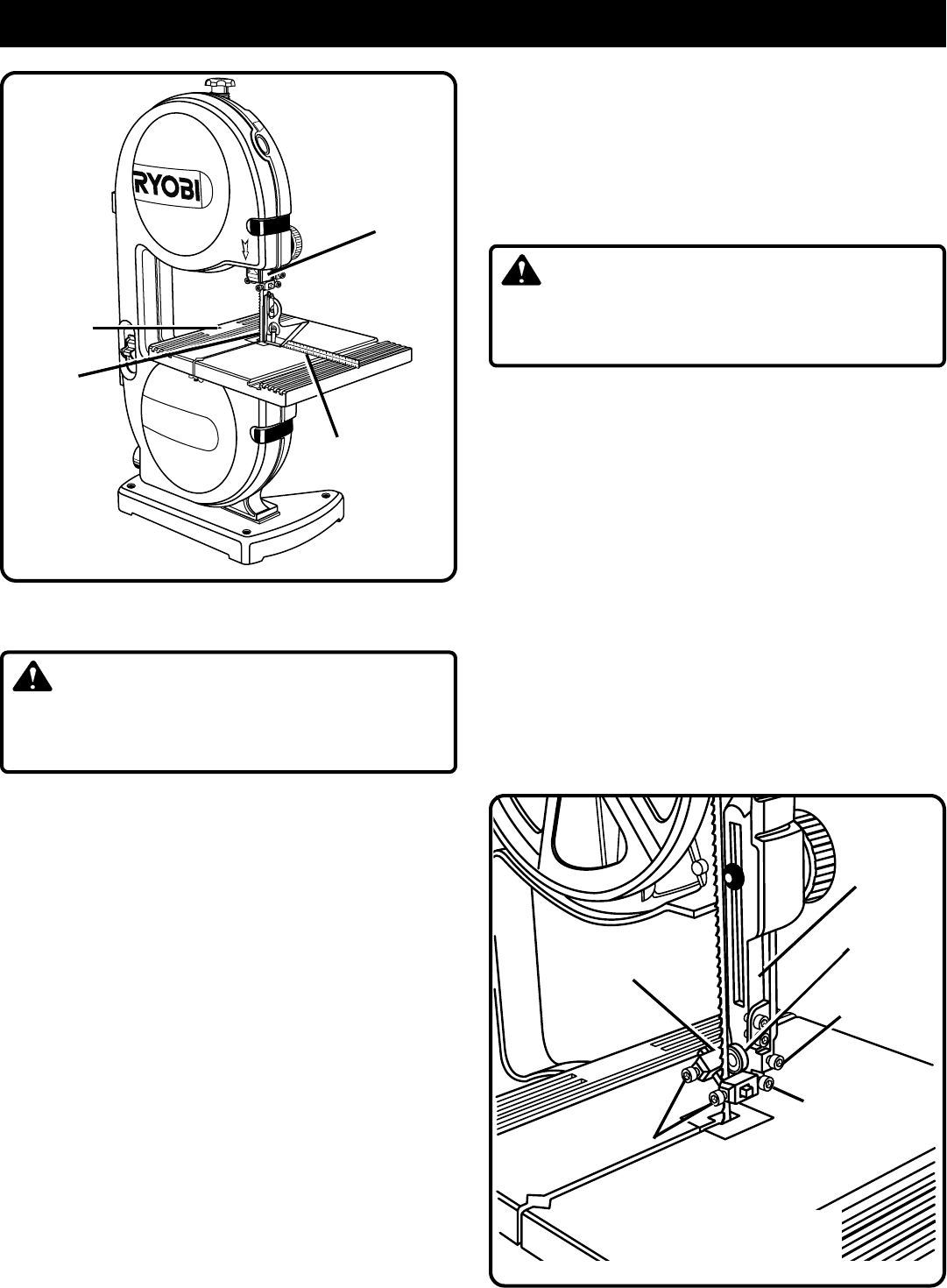

SQUARING THE SAW TABLE TO THE BLADE

See Figure 12.

WARNING:

Failure to turn the saw off, remove the switch key, and

unplug the saw could result in accidental starting causing

possible serious personal injury.

■ Remove the blade guard by loosening the two set screws

with the 4 mm hex key.

■ Turn the lock lever counterclockwise to unlock the blade

guide assembly. Turning the blade guide knob (clockwise

raises the blade guide assembly, counterclockwise lowers

it), position the blade guide assembly about halfway

between the saw table and saw housing. Retighten the

lock lever.

ADJUSTING THRUST BEARINGS, BLADE

GUIDE SUPPORT, AND BLADE GUIDES

See Figures 13, 14, and 15.

The upper and lower blade guides and thrust bearings

support the band saw blade during cutting operations. The

adjustment of the guides and bearings should be checked

whenever a different blade is installed.

To Adjust Thrust Bearings:

The thrust bearings support the back edge of the blade during

cutting. The blade should not contact the thrust bearings when

you stop cutting. It is important that both upper and lower

thrust bearings be adjusted equally.

Note: The thrust bearing screw is the upper cap screw located

on the right side of the blade guide assembly. It is the lower

cap screw on the right side of the saw housing below the

saw table for the lower bearing.

See Figures 13 and 14.

BLADE

GUIDE

ASSEMBLY

BLADE GUIDE

SUPPORT SCREW

BLADE GUIDE

SCREWS

UPPER BLADE

GUIDE SUPPORT

BLADE GUARD REMOVED

FOR CLARIFICATION ONLY

THRUST

BEARING

THRUST BEARING

SCREW

Fig. 13

BLADE GUIDE

ASSEMBLY

ZERO STOP

SET SCREW

Fig. 12

3

M

A

X

I

M

U

M

C

U

T

T

I

N

G

C

A

P

A

C

I

T

Y

O

N

R

E

M

O

V

E

T

O

L

O

C

K

O

9”

B

A

N

D

SA

W

SMALL

COMBINATION

SQUARE

SAW

BLADE