Page 14

4. For non-through cuts, use a ruler or other graduated

straight-edge to measure from the table surface to the

tip of the uppermost tooth on the blade.

TO ADJUST THE RIP FENCE

To reposition the rip fence, lift the lock down handle to the

Up position (parallel to the fence). Use the indicator on the

fence to slide the fence to the desired position. Make sure

the front bar on the rip fence is flush against the front rail.

Then move the lock down handle to the Down position

(perpendicular to the fence).

TO ADJUST TENSION ON THE RIP FENCE

To avoid risk of kickback and to ensure accuracy, the rip

fence must be securely attached to the front rail and rear

edge. If there is lateral play in the fence, tighten the

adjustment nut at the back of the fence. If the rip fence lock

down lever is too tight, loosen the adjustment nut.

WARNING:

The rip fence must be positioned parallel to the miter

gauge channel to prevent risk of kickback.

To ensure proper alignment, use a framing square to measure

the distance from the front end of the rip fence to either of

the miter gauge channels. Then measure from the rear end

of the fence to the same miter gauge channel. If the two

measurements are not the same, reposition the rear end of

the fence and measure again.

TO ADJUST THE MITER GAUGE

To adjust the miter gauge, simply loosen the lock knob and

rotate the miter gauge to the desired position. Then tighten

the lock knob.

NOTE: There are two miter gauge channels, one on either

side of the blade. When making a 90° cross-cut, you can

use either miter gauge channel. When making a beveled

cross cut (the blade tilted in relation to the table) the miter

gauge should be located in the slot on the right so that the

blade is tilted away from the miter gauge and your hands.

Reset the Bevel Indicator to 90° by loosening the screw

holding the indicator. Line up the red line on the indicator

with the 0° mark on the bevel scale.

TO ADJUST THE 45° POSITIVE STOP

Make sure the saw is unplugged from the power source.

Raise the blade to the maximum height by turning the blade

control wheel counterclockwise. Turn the bevel lock lever to

the left to loosen the bevel.

Next, push the blade control wheel in and rotate

counterclockwise until it stops. Check the blade position using

the angled corner of a combination square or triangle.

ADJUSTMENTS

Fig. 11

90° POSITIVE STOP

ADJUSTMENT SCREW

If the blade angle is greater than 45°, turn the 45° Positive

Stop Adjustment Screw counterclockwise 1 turn and rotate

the bevel control wheel counterclockwise until it stops.

Recheck the blade position. Continue this process until the

blade is at 45°. Tighten the bevel control lever.

If the blade angle is less than 45°, use the combination

square or triangle to position the blade at 45°. Turn the 45°

Positive Stop Adjustment Screw clockwise until it stops.

Tighten the bevel control lever.

Reset the Bevel Indicator to 45° by loosening the screw

holding the indicator. Line up the red line on the indicator

with the 45° mark on the bevel scale.

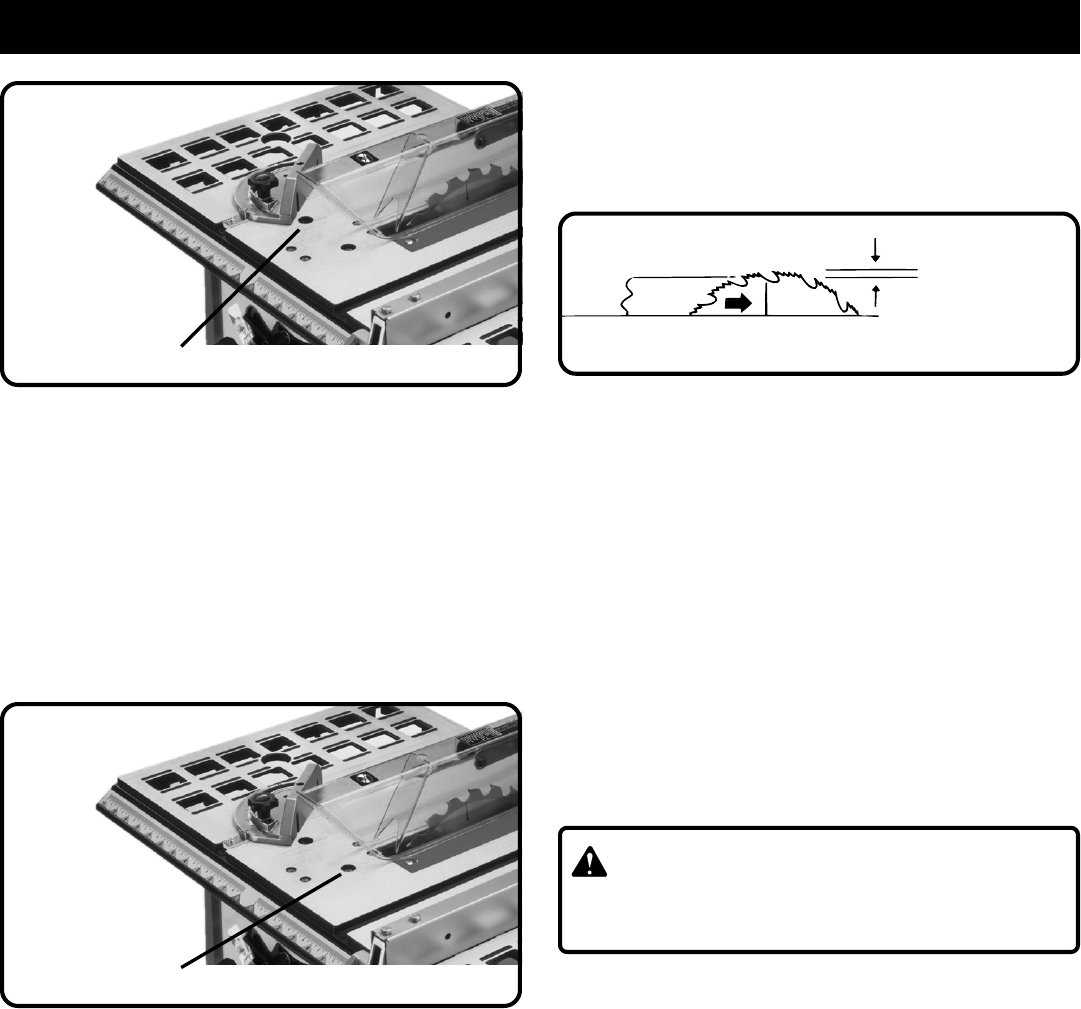

TO ADJUST THE BLADE HEIGHT

1. Disconnect saw from power supply.

2. Turn blade control wheel. Turning it clockwise lowers the

blade. Turning it counterclockwise raises it.

Fig. 13

Fig. 12

45° POSITIVE STOP

ADJUSTMENT SCREW

APPROXIMATELY

1/8”

3. For through-cuts, place the workpiece to be cut flush

against the blade. Set the blade so that the tips of the

uppermost tooth are about an 1/8" (3 mm) higher than

the workpiece and the valley between the teeth (gullet)

is lower than the workpiece as in Figure 13.