18

PROPER FEEDING

The right feed is neither too fast nor too slow. It is the rate

at which the bit is being advanced firmly and surely to

produce a continuous spiral of uniform chips. A feed to

fast produces large, individual chips and a feed to slow

creates sawdust. If you are making a small diameter,

shallow groove in soft, dry wood, the proper feed may be

as fast as you can travel your router along your guide

line. On the other hand, if the bit is large, the cut is deep,

or the wood is hard, the proper feed may be a very slow

one. Additionally, a cross-grain cut may require a slower

pace than an identical with-grain cut in the same

workpiece.

There is no fixed rule. You will learn by experience from

practice and use. The best rate of feed is determined by

listening to the sound of the router motor and by feeling

the progress of each cut. Always test a cut on a scrap

piece of the workpiece wood.

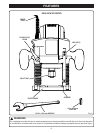

DIRECTION (EXTERNAL)

See Figure 19.

When routing, the cutter rotates clockwise. Therefore,

you should feed the router into the workpiece from left to

right. When fed from left to right, the rotation of the cutter

pulls the router against the workpiece. If fed in the

opposite direction, the rotation forces of the spinning bit

will tend to throw the router away from the workpiece.

This action could cause you to lose control of the router.

The router motor and bit revolve in a clockwise direction.

This gives the tool a slight tendency to twist (in your

hands) in a counterclockwise direction, especially when

the motor revs up.

Because of the extremely high speed of bit rotation

during a “proper feeding” operation, there is very little

kickback to contend with under normal conditions.

However, should the bit strike a knot, hard grain, foreign

object, etc. that would affect the normal progress of the

cutting action, there will be a slight kickback—sufficient

to spoil the trueness of your cut if you are not prepared.

Such a kickback is always in the direction opposite to the

direction of bit rotation.

To guard against such a kickback, plan your setup and

direction of feed so that you will always be thrusting the

tool—to hold it against whatever you are using to guide

the cut—in the same direction that the leading edge of

the bit is moving. In short, the thrust should be in a

direction that keeps the sharp edges of the bit continuously

biting straight into new (uncut) wood.

DIRECTION (INTERNAL)

Whenever you are routing a groove, your travel should

be in a direction that places whatever guide you are

using at the right-hand side. In short, when the guide is

positioned as shown in the first part of Figure 20, tool

travel should be left to right and counterclockwise around

curves. When the guide is positioned as shown in the

OPERATION

ROUTER FEED

DIRECTION

ROUTER FEED

DIRECTION

ROUT END GRAINS FIRST

BIT

ROTATION

Fig. 19

Fig. 20

ROUTER FEED

DIRECTION

THRUST

GUIDE OUTSIDE

GUIDE

FEED

THRUST

BIT ROTATION

GUIDE

FEED

GUIDE INSIDE

BIT ROTATION

second part of Figure 20, tool travel should be right to left

and clockwise around curves. If there is a choice, the first

setup is generally the easiest to use. In either case, the

sideways thrust you use is against the guide.

SPEED CONTROL

In general, if the material being cut is hard, the cutter size

is large, or the depth of cut is deep - maximum 1/8 in. (3.2

mm), then your router should be run at slower speeds.

When these situations exist, turn the variable speed

control selector until the desired speed is reached.

NOTE: Carbide cutters cut at higher speeds than steel

cutters and should be used when cutting very hard

materials. Keep cutters sharp at all times.