20

OPERATION

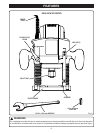

DEPTH OF CUT

As previously mentioned, the depth of cut is important

because it affects the rate of feed that, in turn, affects the

quality of the cut (and, also, the possibility of damage to

your router motor and bit). A deep cut requires a slower

feed than a shallow one, and a too deep cut will cause

you to slow the feed so much that the bit is no longer

cutting, it is scraping, instead.

Making a deep cut is never advisable. The smaller bits

— especially those only 1/16 inch (1.6 mm) in diameter

— are easily broken off when subjected to too much side

thrust. A large enough bit may not be broken, but if the

cut is too deep a rough cut will result — and it may be very

difficult to guide and control the bit as desired. For these

reasons, we recommend that you do not exceed 1/8 in.

(3.2 mm) depth of cut in a single pass, regardless of the

bit size or the softness or condition of the workpiece.

See

Figure 22.

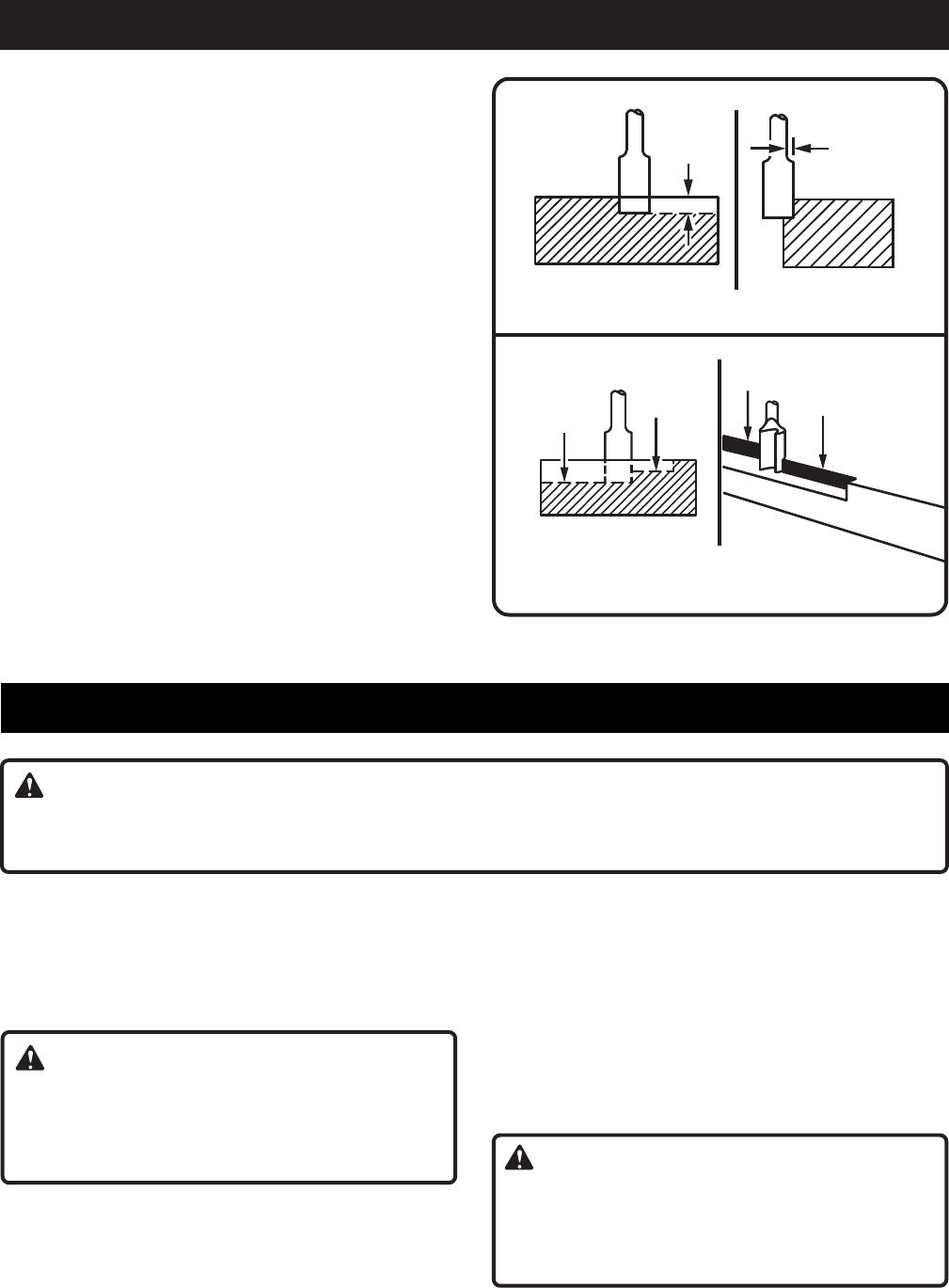

To make deeper cuts it is therefore necessary to make

as many successive passes as required, lowering the bit

1/8 in. (3.2 mm) for each new pass. In order to save time,

do all the cutting necessary at one depth setting, before

lowering the bit for the next pass. This will also assure a

uniform depth when the final pass is completed.

See

Figure 23.

Fig. 22

WIDTH

OF CUT

DEPTH

OF CUT

1ST.

PASS

2ND.

PASS

1ST.

PASS

2ND.

PASS

Fig. 23

MAINTENANCE

GENERAL

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use.

Use clean cloths to remove dirt, carbon dust, etc.

WARNING:

Do not at any time let brake fluids, gasoline, petro-

leum-based products, penetrating oils, etc. come in

contact with plastic parts. They contain chemicals

that can damage, weaken, or destroy plastic.

Electric tools used on fiberglass material, wallboard,

spackling compounds, or plaster are subject to

accelerated wear and possible premature failure, as the

fiberglass chips and grindings are highly abrasive to

bearings, brushes, commutators, etc. Consequently, we

do not recommended that this tool be used for extended

work on these types of materials. If, however, you do

work with any of these materials, it is extremely important

that you clean the tool frequently by blowing it with an air

jet.

WARNING:

Always wear safety goggles or safety glasses with

side shields during power tool operation or when

blowing dust. If operation is dusty, also wear a dust

mask.

WARNING:

When servicing use only identical Ryobi replacement parts. Use of any other parts may create a hazard or cause

product damage.