14

ADJUSTMENTS

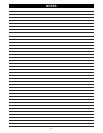

INSERTING THROAT PLATES

See Figure 12.

The throat plate provides a stable surface around the

cutter and prevents objects from falling through the

throat and damaging the spindle.

The proper size throat plate depends on the size and

shape of the cutter. When inserted, the throat plate

opening should be within approximately 1/4 in.

(6.4 mm) of the outermost edge of the cutter.

Follow these directions to insert throat plates.

Q Position the throat plate over the throat opening in

the router table.

Q Align the tab in the throat plate with the slot in the

throat opening.

Q Snap throat plate down and into place as shown.

NOTE: To remove throat plate, pull gently until the

throat plate snaps out.

WARNING:

Never attempt to operate router table without the

throat plate in place. Failure to do so could result in

the workpiece jamming or objects falling into the

rotating spindle, which could cause serious personal

injury.

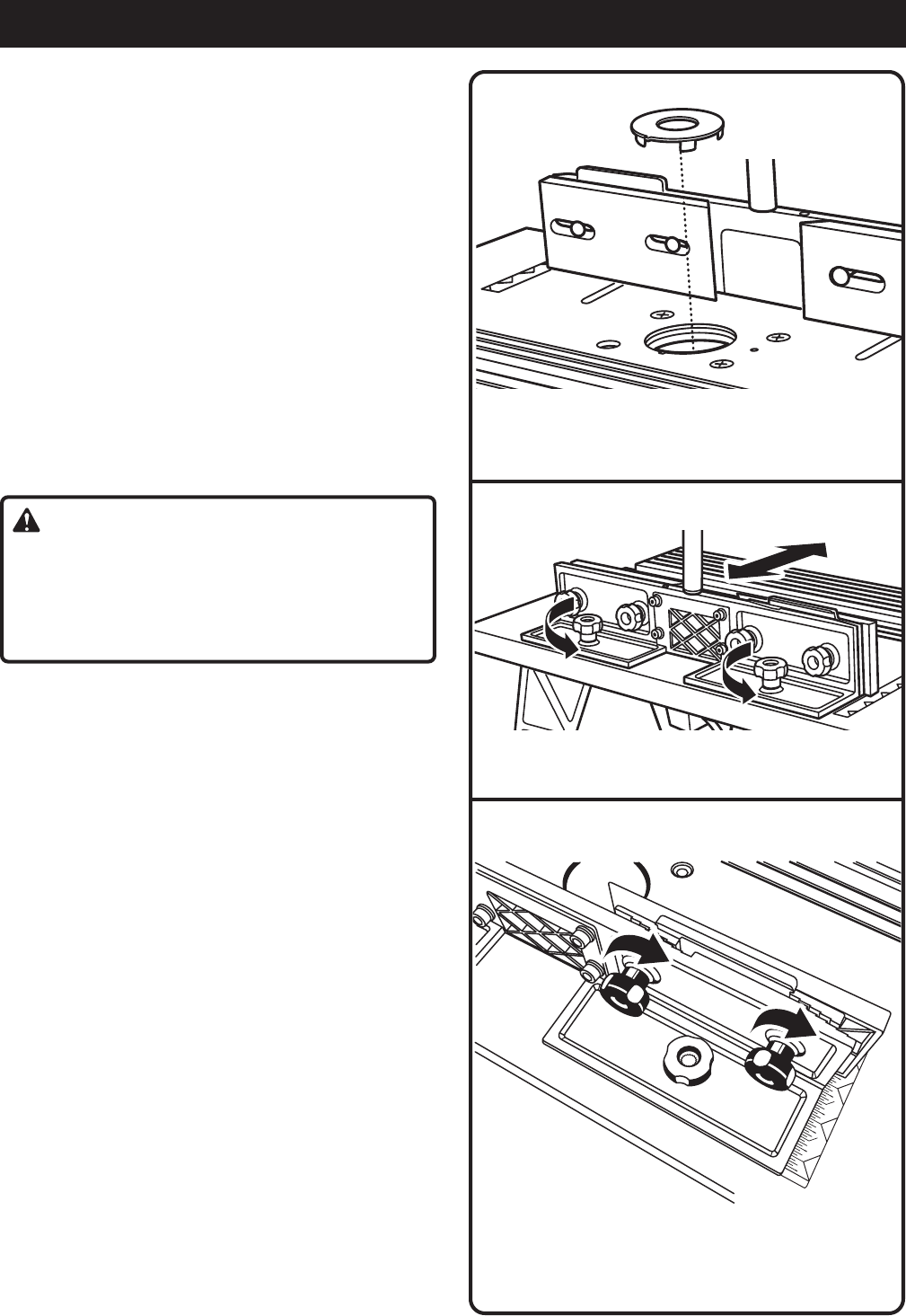

POSITIONING THE FENCE

The fence enables you to support and guide the

workpiece.

See Figure 13.

Follow these directions to position the fence.

Q Loosen the fence lock knobs.

Q Position the fence the proper distance from the cut-

ter based on the amount of material you plan to

remove.

Q Tighten the fence lock knobs.

ADJUSTING THE STEP RISERS

See Figure 14.

The step risers, located on the outfeed side of the fence,

enable you to support the workpiece as it exits the cutter.

The step risers provide support for routing operations

that remove up to 1/8 in. (3.2 mm) of material. The step

risers are adjustable in 1/32 in. (0.8 mm) increments.

Follow these directions to adjust the step risers.

Q Loosen the knob bolts on the rear of the fence.

Q Push the riser forward and toward the throat.

Q Tighten the knob bolts.

Fig. 12

Fig. 13

Fig. 14

4

3

2

in./po./pulg.

1

2

1

2