ThisDrillPresshas3 speedsaslistedbelow:

620RPM

!300RPM

31OORPM

Seeinsideofbeltguardforspecificplacementofbelts

onpulleys.

SPINDLE SPEEDS BN R.P.M.

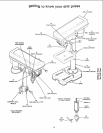

1, BELT GUARD .... Covers pulleys and belt during

operation of drill press.

2. BELT TENSION LOCK HANDLE ... Tightening

handle locks motor bracket support to maintain cor-

rect belt distance and tension.

3. HEAD LOCK :SET SCREWS... Locks the head

to the column. ALWAYS have them locked in place

while operating the drill press.

4, TABLE SUPPORT ... Rides on column to support

table.

5. COLUMN SUPPORT . . . Supports column and

provides mounting holes for column to base.

6. SUPPORT LOCK HANDLE... Tightening locks

table support to column. Always have it locked in

place while operating the Drill Press.

7. BASE... Supports Drill Press. For additional sta-

bility, holes are provided in base to bolt Drill Press

to bench (See "Additional Safety Instructions for

Drill Presses.")

8. SPRING CAP... Provides means to adjust quill

spring tension.

9. DEPTH POINTER... Indicates drilling depth and

is located between stop nuts.

10. DEPTH SCALE . .. Shows depth of hole being

drilled in inches and millimeters.

11. COLUMN... Connects head, table, and base on

a one-piece tube for easy alignment and move-

ment.

t2. BEVEL SCALE .... Shows degree table is tilted

for bevel operations. Scale is mounted on table

support. It if to be used for quick reference where

accuracy _snot critical.

t3. TABLE BEVEL LOCK... Locks the table in any

position from O_-45 °.

14. TABLE... Provides working surface to suoport

workpiece.

15. FEED HANDLE... For moving the chuck up or

down. One or two of the handles may be removed

if necessary whenever the workpiece is of such

unusual shape that it interferes with the handles,

16. CHUCK... Holds drill bit or other recommended

accessory to perform desired operations.

17. FEED STOP ROD... Holds stop nuts for drilling

to specific depths.

t8. STOP NUTS... Limits the downward movement

of the quill at any desired point within its t_avel,

and prevents the pointer from moving upward.

19. "ON-OFF SWITCH... Has locking feature. THIS

FEATURE IS INTENDED TO PREVENT UNAU-

THORIZED AND POSSIBLE HAZARDOUS USE

BY CHILDREN AND OTHERS.

20. CHUCK KEY . . . It is a self-ejecting chuck key

which will "pop" out of the chuck when you let go

of it, This action is designed to help prevent throw-

ing of the chuck key from the chuck when power

is turned "ON". Do not use any other key as a

substitute, order a new one if damaged or lost.

21. BELT TENSION... Refer to section "Tensioning

Belt" (Page 13).

22. DRILLING SPEED... Can be changed by placing

the belt in any of the STEPS (grooves) in the pul-

leys. See Spindle Speed chart inside belt guard.

To determine the approximate drilling speed, refer to

the table inside the belt guard.

16