basic dr!IS press operation

Follow the following instructions for operating your drill

press to get the best results and to minimize the likeli-

hood of personal injury.

WARNING: FOR YOUR OWN SAFETY, ALWAYS

OBSERVE THE SAFETY PRECAUTmONS HERE AND

ON PAGES 2, 3, AND 4.

!. Protection: Eyes, Hands, Face, Ears and Body

WARNING: TO AVOID BEING PULLED iNTO

THE SPINNING TOOL --

1. Do NOT wear:

-- gloves

-- necktie

-- loose clothing

-- jewelry

2. Do tie back long hair

a. If any part of your drill press is missing, malfunc-

tioning, has been damaged or broken.., such

as the motor switch, or other operating control,

a safety device or the power cord . . . cease

operating immediately until the particular part

is properly repaired or replaced.

b. Never place your fingers in a position where

they could contact the drill or other cutting tool

if the workpiece should unexpectedly shift or

your hand should slip.

c. To avoid injury from parts thrown by the spring,

follow instructions exactly as given and shown

in adjusting spring tension of quill.

d. To prevent the workpiece from being torn from

your hands, spinning of the tool, shattering the

toot or being thrown, always properly support

your work so it won't shift or bind on the tool:

-- Always position BACKUP MATERIAL (use

beneath the workpiece) to contact the left

side of the column.

-- Whenever possible, position the WORK-

PIECE to contact the left side of the col-

umn-if it is too short or the table is tilted,

clamp solidly to the table. Use table slots or

clamping ledge around the outside edge of

the table.

-- When using a drill press VICE, always fasten

it to a table,

-- Never do any work "FREE HAND" (hand-

holding workpiece rather than supporting it

on the table), except when polishing.

-- Securely !ock Head and Support to Column,

Table Arm to support, and Table to Table

Arm before operating drill press.

-- Never move the Head or Table while the

toot is running.

-- Before starting the operation, jog the motor

switch to make sure the drill or other cutting

toot does not wobble or cause vibration.

-- If a workpiece overhangs the table such that

it witt fall or tip if not held, clamp it to the

table or provide auxiliary support.

-- Use fixtures for unusual operations to

adequately hold, guide and position work-

piece.

-- Use the SPINDLE SPEED recommended

for the specific operation and workpiece ma-

terial--check the panel inside the guard

cover for drilling information; for acces-

sories, refer to the instructions provided with

the accessories.

f. Never climb on the drill press Table, it could

break or put! the entire drill press down on you.

g. Turn the motor Switch Off and put away the

Switch Key when leaving the drill press.

h. To avoid injury from thrown work or toot contact,

do NOT perform layout, assembly, or setup

work on the table while the cutting tool is rotat-

ing.

2. Use only accessories designed for this drill

press to avoid serious injury from thrown bro-

ken parts or work pieces.

a. Holesaws must NEVER be operated on this drill

press at a speed greater than 400 RPM

b. Drum sanders must NEVER be operated on

this drill press at a speed greater than 1800

RPM.

c, Do not install or use any drill that exceeds 7" in

length or extends 6" below the chuck jaws. They

can suddenly bend outward or break.

d. Do not use wire wheels, router bits, shaper cut-

ters, circle (fly) cutters or rotary planers on the

drill press.

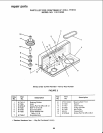

iNSTALLING DRILLS

Insert drill into chuck far enough to obtain maximum

GRIPPING of the CHUCK JAWS . • . the jaws are

approx. 1" long. When using a small drill do not insert

it so far that the jaws touch the flutes (spiral grooves)

of the drill.

Make sure that the drill is CENTERED in the chuck

before tightening the chuck with the key.

Tighten the drill sufficiently, so that it does not SLIP

while drilling.

Turn the chuck key clockwise to tighten--coun-

terclockwise to loosen.

JAWS

:HUCK KEY

o_

€_

_t,--

o.- _o

._.oo

=n

m

_.=

19