-38-

M1113 18" Wood/Metal Bandsaw

SERVICE

SERVICE

This section covers the most common service adjustments

or procedures that may need to be made during the life

of your machine.

If you require additional machine service not included

in this section, please contact Woodstock International

Technical Support at (360) 734-3482 or send e-mail to:

tech-support@shopfox.biz

.

General

MAKE SURE that your machine is

unplugged during all service proce

-

dures! If this warning is ignored, seri

-

ous personal injury may occur.

To ensure optimum power transfer from the motor to the

blade, the V-belts must be in good condition and operate

under proper tension. Check belt tension at least every 3

months—more often if the bandsaw is used daily.

V-belts

stretch with use and must be periodically re-tensioned.

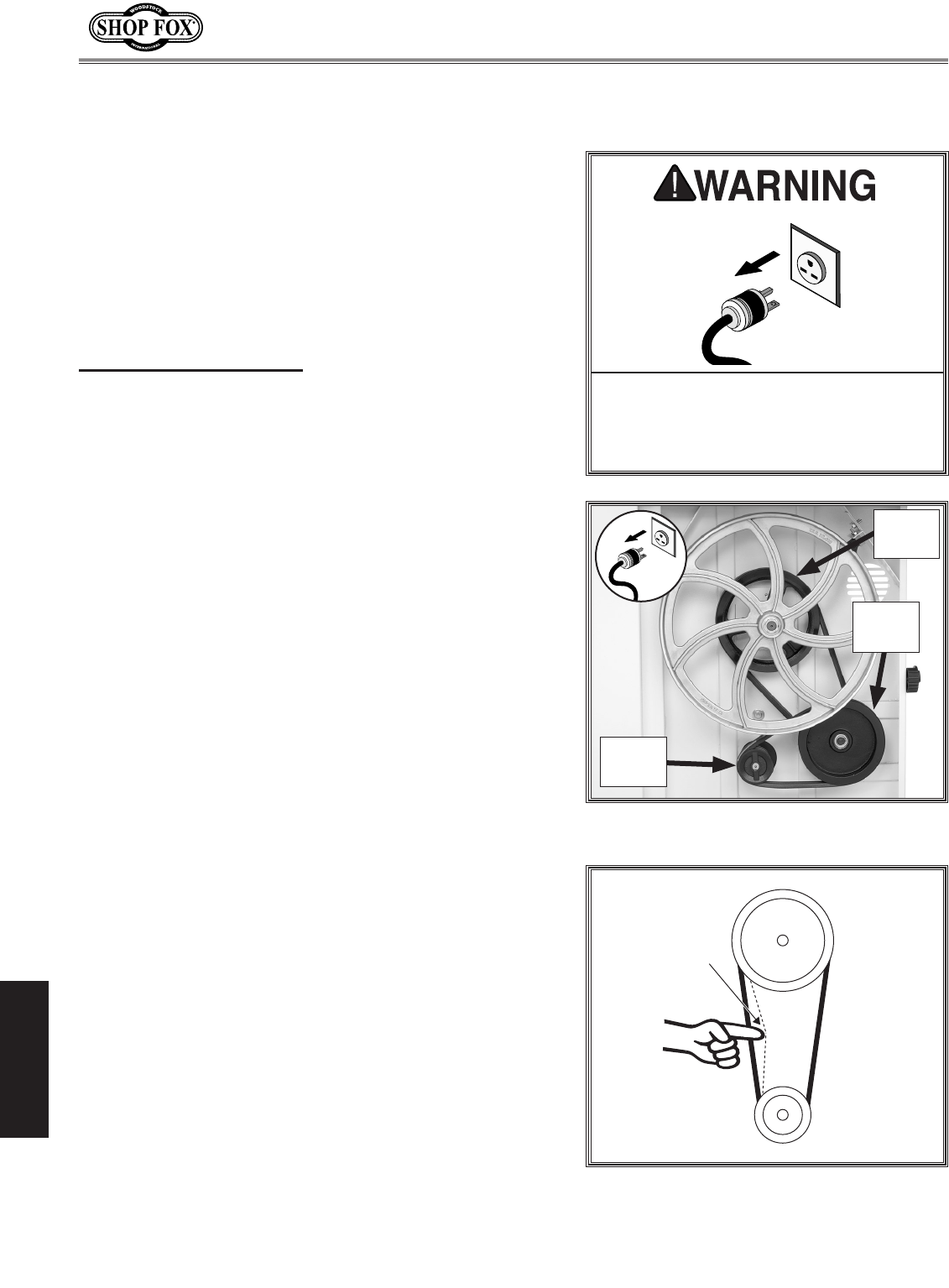

Accessing V-Belts

1. DISCONNECT BANDSAW FROM POWER!

2. Remove the bandsaw blade.

3. Remove the lower wheel by removing the hex bolt at

the center of the wheel, then sliding the wheel off

the shaft. (The hex nut has left handed threads, so

you must turn it clockwise to loosen

it.) You now have

access to the V-belts for inspection or ser

vice (see

Figure 49).

Checking V-Belts

1. Follow all previous instructions for Accessing V-

Belts.

2. Push the center of each V-belt (Figure 50), using

moderate force.

Deflection should be about

1

⁄4".

If deflection is more than

1

⁄4", tension that V-belt

(Page 39) before doing Step 4.

3. Use a flashlight to inspect the belt. If a V-belt is

cracked, frayed, or glazed, replace it soon.

4. Replace the pulley cover, lower wheel, and blade;

then close the lower wheel cover.

Servicing V-Belts

Figure 50. Belt deflection.

Figure 49. Pulleys and V-belts.

Wheel

Pulley

Idler

Pulley

Motor

Pulley

1

⁄4"