-38-

W1755 6" Parallelogram Jointer

SERVICE

V-Belt Replacement

Inspect the V-belt closely; if you notice fraying, cracking,

glazing, or any other damage, replace the belt. A worn or

damaged V-belt will not provide optimum power transmis

-

sion from the motor to the cutterhead.

Overly loose V-belts can slip on the pulleys and burn up

or cause poor machine performance. Overly tight V-belts

cause unecessary wear on the motor and pully bearings,

leading to a shortened lifespan.

To replace the V-belts, do these steps:

1. DISCONNECT JOINTER FROM POWER SOURCE!

2. Open the back cover.

3. Loosen the motor bracket bolts shown by the black

arrows in

Figure 64.

4. Roll off the old V-belt and roll on the new V-belt, as

shown in

Figure 65.

5. Check the alignment of the pulleys to make sure the

V-belt is straight up and down.

— If the pulleys are aligned, skip to Step 9

.

— If the pulleys are NOT aligned, refer to

Pully

Alignment on Page 39 and align the pulleys.

6. Pull down on the motor with one hand to keep ten-

sion on the V-belt, and tighten the motor bracket

bolts with your other hand.

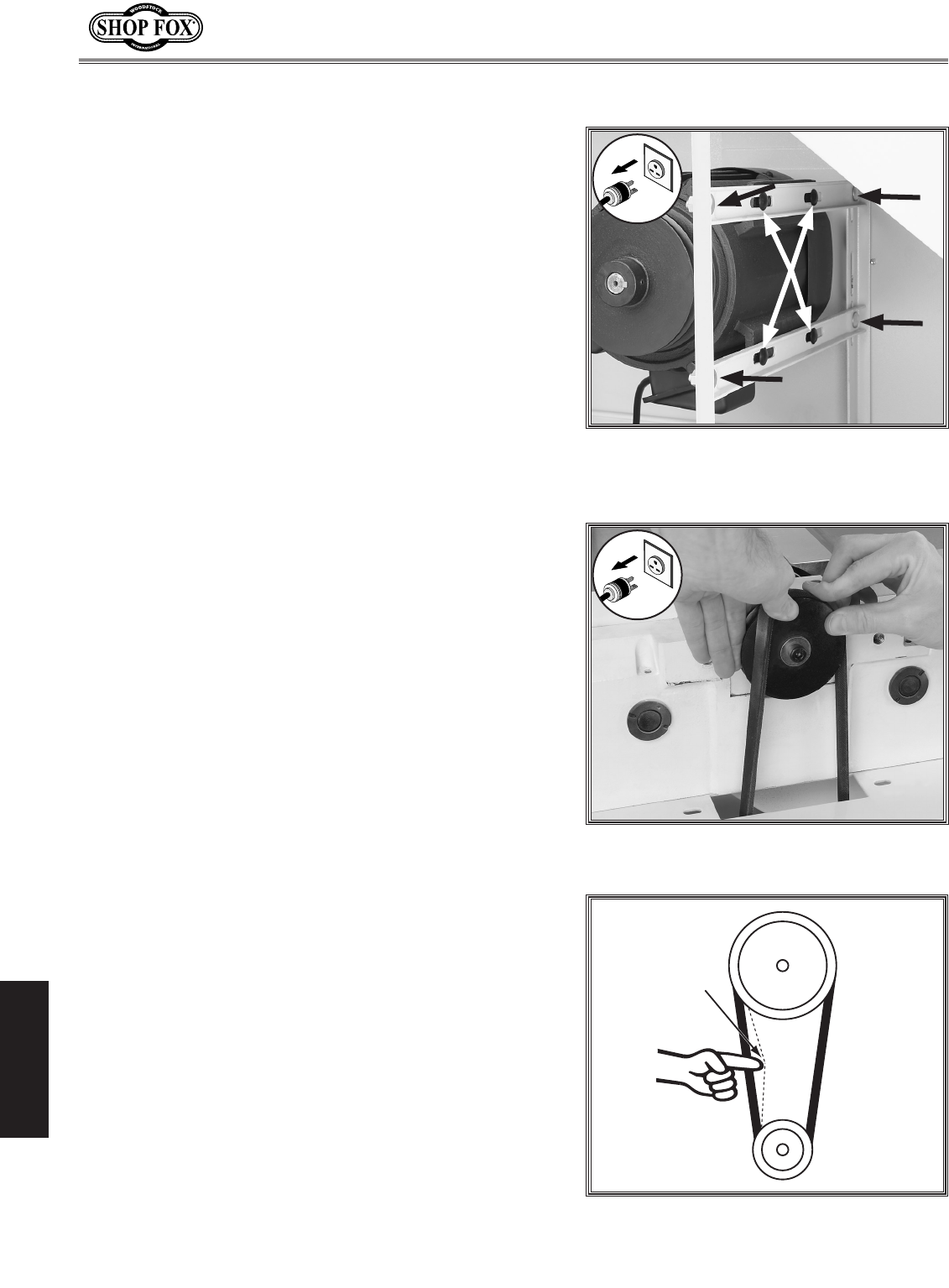

7. Push the center of the V-belt as illustrated in Figure

66, using moderate force. When tensioned correctly,

the deflection should be approximately

1

⁄4".

— If the deflection is not correct, loosen the motor

bracket bolts and repeat Steps 9–10

.

8. Reinstall the belt guard.

9. Replace the cover on the back of the jointer stand.

Figure 65. Rolling the V-belt onto the

cutterhead pulley.

Figure 64. Motor bracket bolts (black

arrows) and motor mount bolts (white

arrows).

Figure 66. Checking belt deflection.