DESCRIPTION OF THE MACHI

NE AND ITS OPERATION.

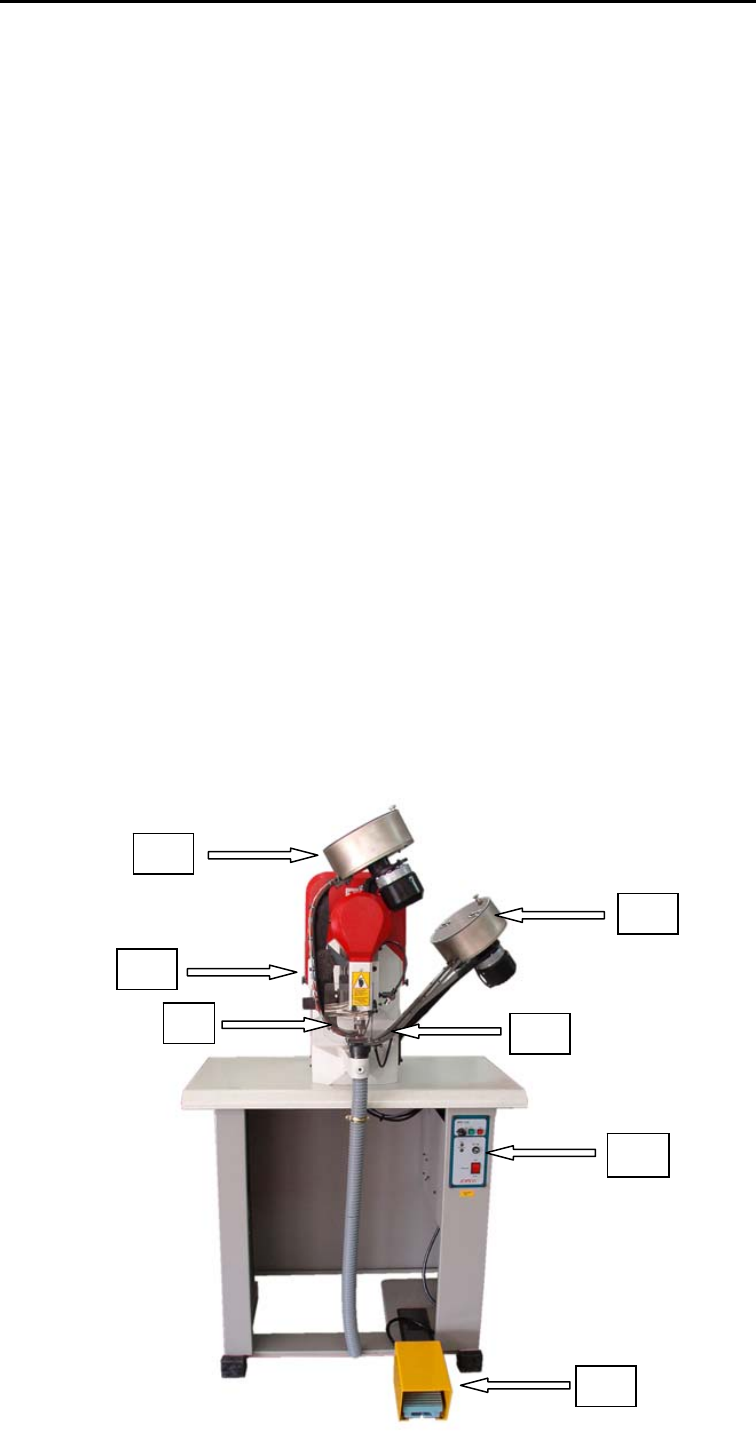

MACHINE MODEL PG-239. AUTOMATIC ELECTRONIC WITH TWO HOPPER BOXES FOR

PLACING GROMMET AND WASHER.

The machine consists of a metallic stand with a wood base on which the machine is mounted. The

pedal and the electronic equipment that control the machine are located in the stand.

The head of the machine is comprised of a machine housing and two raceways (one on each side).

The moving parts in the machine are located inside the housing, such as: the main motor, axles,

eccentrics, bearings, etc. The grommets and the washers use the two raceways to descend.

The PG-239 model is designed to automatically place the grommets with washers, the grommet

without the washer, or to punch holes in the material. Facing the machine, the grommets are placed

in the left hopper box “ A1 ” and the washers in hopper box “ B1 ”.

Both hopper boxes are rotated by individual 24V motors. The grommets that descend along the left

raceway “ A2 ” are held by a small finger, which stops them from falling.

Lower horizontal guides hold the washers descending along the right raceway “ B2 ”.

The machine is controlled by an electronic unit designated IMO V3 “ C ”, located inside the

mounting stand. The IMO V3 unit receives an electric signal through pedal “ D ” that allows the

main motor “ E ”located behind the head, to quickly rotate and haul the

flywheel (part no. 274) with a belt making a 360° rotation causing the motor to stop sharply.

The flywheel (part no. 274) has a main shaft (part no. 207) that joins the plunger with the other

moving parts. By rotating 360°, it exerts pressure on the driving stem and therefore the grommeting

action is completed.

The top set spindle (part no. 218) inside the top set (part no.217) inserts itself inside the grommet

and pulls it down from raceway “ A2 ”. At the same time the slide (part no. 297) pushes the washer

from the slide track and places it exactly on top of the bottom set (part no. 219).

A1

B1

A2

E

B2

C

D