10.

Assembly and adjustments

To reduce the risk of injury, never

c

onnect plug to power source outlet

u

ntil all assembly steps are completed.

Tools needed for assembly

• Adjustable wrench

• Phillips

®

screwdriver

• Hammer and block of wood

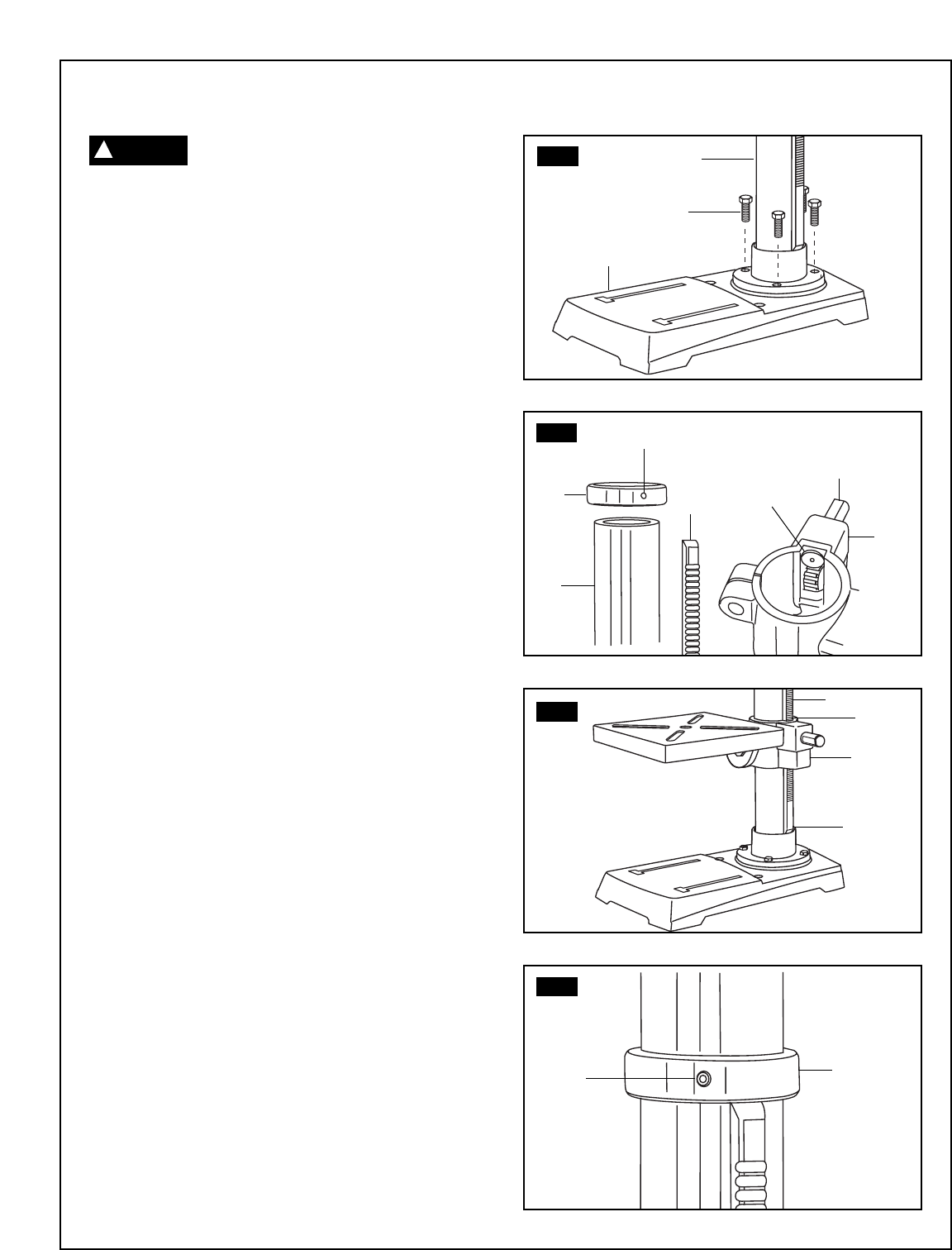

Base to column (Fig. 3)

1. Set the base (1) on the floor.

2. Place the column tube (2) on the base (1), align the

column support holes with the base holes.

3. Install a bolt (3) in each column support hole and

tighten with the wrench.

Table to column (Fig. 4–7)

1. Loosen set screw (2) in column ring (1) and remove

the ring.

2. Remove the rack (3) from the column (4).

3. Insert worm shaft (5) into the hole of the table support

crank handle (6) from inside the table support. The

worm shaft (5) should extend outside the housing

about 1”.

4. Insert the rack (3) into the geared groove of the table

support (6). Make sure the worm shaft (5) on the

inside of the table support is engaged with the teeth

of the rack. The table support should sit at the center

of the rack.

5. Slide the table support and rack assembly (3, 5, 6)

down together onto the column. Insert the bottom

edge of the rack into the lip (7) of the column support.

HOLD IN THIS POSITION until step 6 is completed.

6.

Place the collar

(1) bevel side down over the rack.

Tighten the set screw (2) with the 3 mm Allen wrench

to hold the rack in position.

Note: Make sure there is enough clearance to allow the

table to rotate around the column. The collar must sit

loosely over rack and not angled on the column. To

avoid column or collar damage, only tighten the set

screw enough to keep collar in place (Figure 6).

FIG. 3

FIG. 4

FIG. 5

FIG. 6

2

3

1

1

4

2

3

6

5

5

6

7

3

5

2

1

W

ARNING

!