15.

Assembly and adjustments

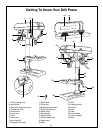

To square the table to the head (Fig. 20)

1. Insert a 3" (7.6 cm) drill bit (1) into the chuck (2) and

tighten.

2. Raise and lock the table (3) about 1" (2.5 cm) from

the end of the drill bit.

3. Place a combination square (4) on the table as

shown. The drill bit should be parallel to the straight

edge of the square.

4. If an adjustment is needed, loosen the bevel lock (5)

with a wrench.

5. Square the table to the bit by tilting the table.

6. Tighten the bevel lock bolt (5) when square.

Drilling depth (Fig. 21)

1. To stop the drill at a specific depth for consistent and

repetitive drilling, loosen the depth scale lock (1)

located on the depth scale hub (2).

2. Turn the hub until the pointer (3) is aligned to the

desired depth on the scale.

3. Tighten the depth scale lock (1). the chuck will stop

after traveling downward to the distance selected.

Note: All the necessary adjustments for the working of

your drill press have been done at the factory. Please

do not modify them. However, because of normal wear

and tear of your tool, some readjustments might be

necessary.

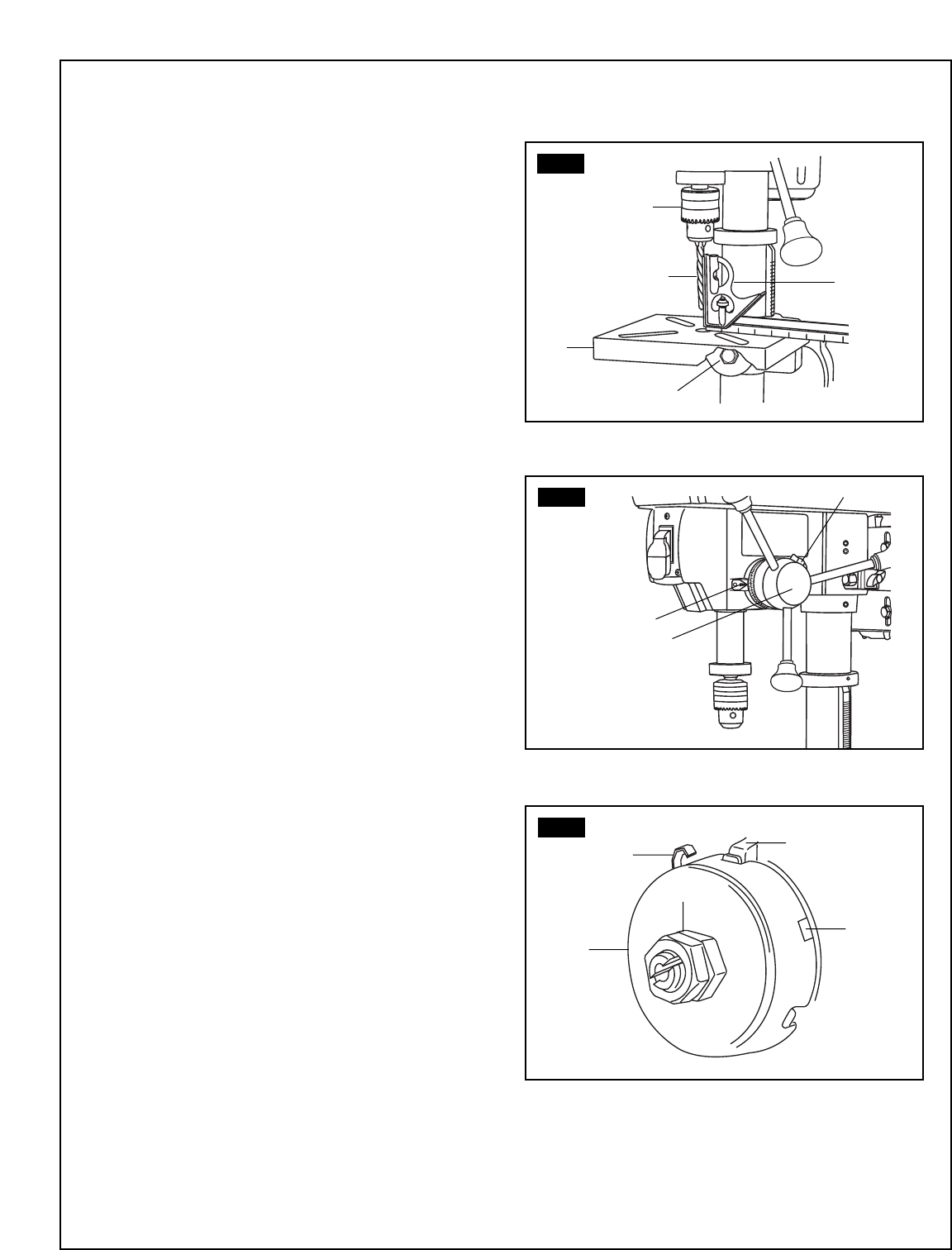

Spindle return spring (Fig. 22)

The spindle is equipped with an auto-return mechanism.

The main components are a spring and a notched

housing. The spring was properly adjusted at the factory

and should not be readjusted unless absolutely

necessary. If it needs to be adjusted, proceed as

follows:

1. Unplug the drill press.

2. Place a screwdriver into the loop

(1) to hold the

spring in place.

3. Loosen the two housing nuts (2) approximately 1/4"

(6 mm). Do not remove the nuts from the threaded

shaft.

4. While firmly holding the spring housing (3), carefully

pull it out until it clears the raised notch (4). Turn it until

the next notch (5) is engaged with the raised notch (to

increase the tension, turn it counterclockwise; to

decrease the tension, turn it clockwise). Tighten the two

housing nuts.

IMPORTANT! Do not overtighten the two nuts. If the

nuts are tightened too much, the movement of the

spindle and feed handles will be sluggish.

FIG. 20

2

3

1

5

4

FIG. 21

1

3

2

F

FIG. 22

5

1

2

3

4