6

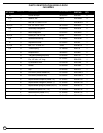

ELECTRICAL SCHEMATIC

BE SURE ALL POWER IS OFF BEFORE ATTEMPTING TO WORK ON THIS EQUIPMENT!

CAUTION: SERVICE WORK SHOULD BE PERFORMED ONLY BY TRAINED & QUALIFIED PERSONNEL

MECHANICAL EDGE-O-DOCK ADJUSTING INSTRUCTIONS

1.) Stand on the ground in front of the leveler. Raise the leveler to

to its vertical position. Place fork truck forks under lip to hold lip

out at nearly level position. Never work directly under fork truck forks.

2.) To adjust the counterbalancing force use the pipe lever

supplied with the dockleveler and a 3/4" open

end wrench or socket. Place the open end of the pipe

over the protrusion on the casting and rotate

down. We recommend one person to rotate the spring

with the pipe handle to the desired strength and

a second person to tighten the 3/4" bolts onto the milled flats.

3.) When the required lifting torsion is reached, return to

leveler to normal operating position. Check the

adjustments made, and, if not lifting properly, repeat the

previous steps to either increase or decrease spring

lifting torsion. If the leveler is bouncing or floating when

the lip is extended, there is too much lifting torsion.

Repeat the previous steps in reverse to reduce lifting torsion.

NOTE:

This is an excellent time to lubricate the grease zerks on the hinges. A standard grease gun will service

these. This must be done regularly for ease of operation and maintenance, as we recommend monthly.

1

P

H

A

S

E

3

P

H

A

S

E

Torsion

spring

Locking

bolt

Decrease

Increase

Milled flats

Interior bar

Mounting

plate

Spring

winding tube