Model 4105 Gas Sensor Module (12/02)

Page: 2

Instruction Manual

2. CAUTIONS WARNINGS &

RECOMMENDATIONS

2.1 INTRODUCTION

Although the sensor module is designed and con-

structed for installation and operation in industrial

applications including “hostile” environments, cau-

tion should be taken to insure that the installation is

in compliance with this instruction manual and that

certain procedures and conditions are avoided.

READ AND UNDERSTAND THIS INSTRUCTION

MANUAL BEFORE OPERATING OR SERVICING

THIS EQUIPMENT.

2.2 WIRING

Electro magnetic and radio frequency interference to

the analog communication between the sensor and

the controller may occur. The manufacturer recom-

mends that extra caution be taken where the installa-

tion is near any sources of these interferences:

Avoid running sensor cable close to high power

cables, radio transmission lines, or cables subject to

pulses of high current. Avoid running cables near

large electric motors or generators.

Use shielded cable in any location which may be ex-

pected to be electrically noisy or where cable is ex-

pected to be in close contact with AC wiring. The

shield should be connected to the controller com-

mon, one side only.

The wiring should be run in either a cable tray or

conduit as required by applicable code and area clas-

sification. Control wiring should not be installed in a

cable tray or conduit with higher voltage and AC cir-

cuits. See Table 2.1 for recommended wire gauge.

Wiring connections at the gas sensor module are as

follows:

Wire# Function Terminal

1 Power PWR

2 Signal SIG OUT

3 Ground GND

Connect an earth ground to the ground screw pro-

vided in the base of the gas sensor module enclo-

sure.

All splices must be via either a lug and terminal sys-

tem or soldered. Improperly spliced cable can result

in corrosion, resistance changes and system errors.

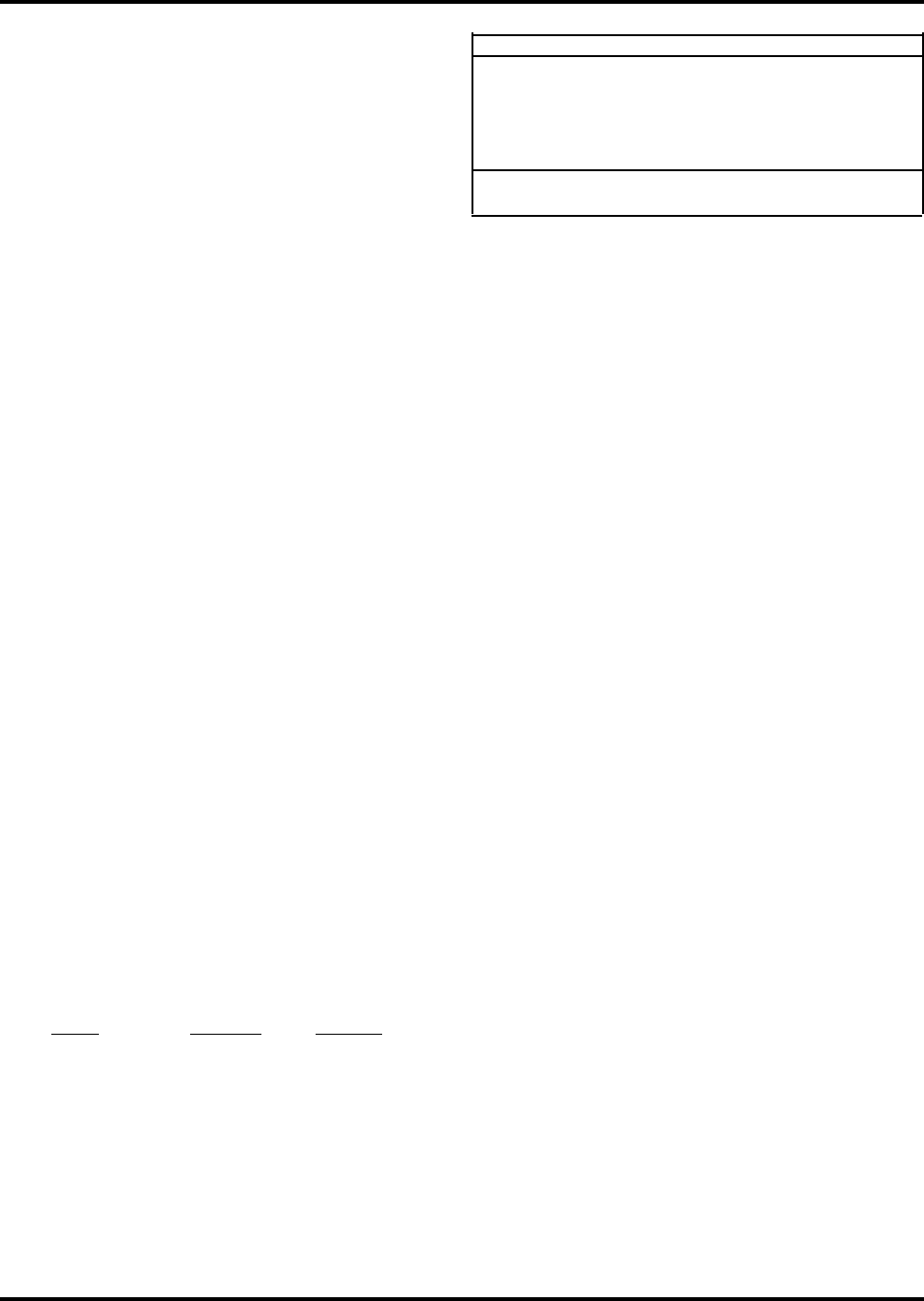

Wire Gauge Maximum Length

20 AWG 2,000 Ft.

18 AWG 3,000 Ft.

16 AWG 4,000 Ft.

14 AWG 6,500 Ft.

12 AWG 9,000 Ft.

Table 2.1

Recommended Wire/Cable Gauge

NOTE: Temperature rating of cable wire insulation

must be above 75

o

C (85

o

C or greater rated wiring is

recommended). If cable runs through higher tempera-

ture environments, it should be specified for that en-

vironment.

2.3 SENSOR MODULES - GENERAL

Sensors should be facing down. Avoid installing sen-

sor modules where they will be unnecessarily exposed

to wind, dust, water (esp. direct hose down), shock,

or vibration. Observe temperature range limitations.

Sensors may be adversely affected by prolonged ex-

posure to certain materials. Loss of sensitivity, or

corrosion, may be gradual if such materials are present

in low concentrations. These materials include: Ha-

lides (compounds containing chlorine, fluorine, bro-

mine, or iodine), silicones, acid vapors, caustic liq-

uids or vapors.

Sensor modules must not be painted. Paint may con-

tain compounds which will contaminate the sensor.

Paint will also cause clogging of the sintered metal

cup and will cause difficulties during attachment of

the calibration fitiing. The module should be tagged

“DO NOT PAINT”.

When sensors are replaced the thread on the sensor

housing must be lubricated with an antizieze com-

pound non-silicone based to avoid metal to metal

binding which will damage the housing threads.

2.4 PREVENTATIVE MAINTENANCE

DUST AND DIRT CONTROL: When calibration is

performed the controller and sensors should be

checked visually to determine if dust or dirt build up

needs to be removed. This cleaning should be done

with dry instruments such as compressed air, cloth

wipes or wisk broom.

WIRING OR CABLE CONDITIONS: Any wiring or

cables which are not in conduit should be checked

once a year for damage to insulation or corrosion

of splice or terminal points.