Instruction Manual

Model 4105 Gas Sensor Module (12/02)

Page: 5

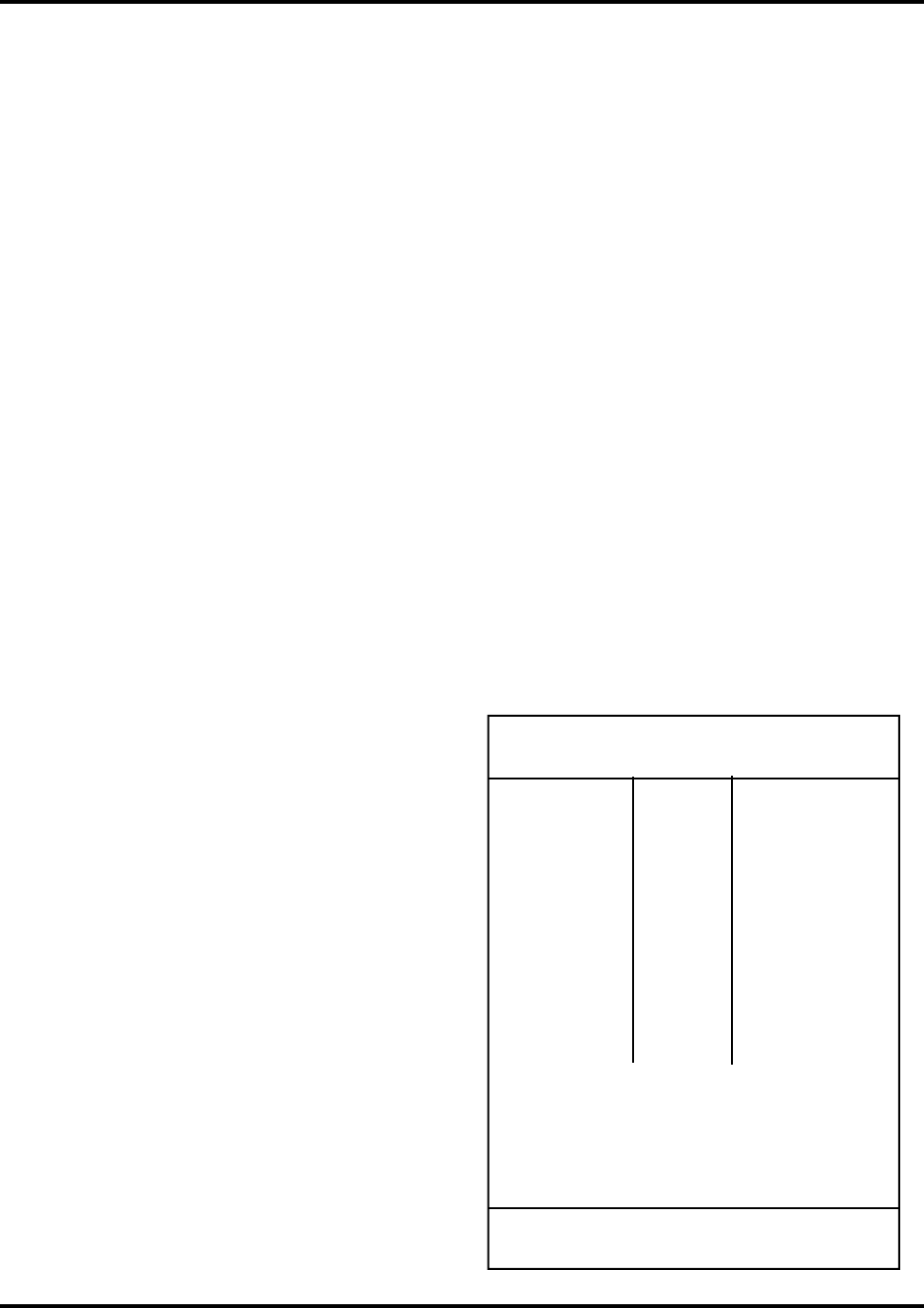

Model Gas Min. Flow Rate

(cc/min)

4105-02 CH

4

100

4105-03 O

2

100

4105-04 CO 150

4105-05 H

2

S 300

4105-06 Cl

2

300

4105-07 H

2

300

4105-10 SO

2

300

4105-12 NO

2

300

4105-21 HCl 300

4105-22 HCN

*

300

4105-25** NH

3

400

4105-26 HF 500

*Note: SO

2

may be used instead of HCN to

calibrate: 10ppm SO

2

= 16 ppm HCN

*Note: H

2

S may be used instead of HCl to

calibrate: 10 ppm H

2

S = 20 ppm HCl

** Note: Use permeation tube for 4105-25

5. CALIBRATION

5.1 Frequency of Calibration

The manufacturer recommends that the gas sensor

module be calibrated every ninety days.

5.2 Calibration Process

The output signal of the gas sensor module is cali-

brated using a span mixture containing a known con-

centration of the gas of interest. The concentration

of the span gas must be within the full scale of the

sensor module and should be either 50% of the full

scale, or approximately equal to the lowest alarm level.

Calibration requires application of the span gas to the

sensor and adjustment of the “SPAN” magnetic switch

making the module signal output and display equiva-

lent to the concentration of sample gas. The 4-20 mA

output is held at 1.5 mA while activated for calibration

to prevent alarms being tripped by calibration gas

application.

5.3 Equipment Required

The following tools and equipment will be required

for calibration:

- Magnetic tool

- Gas Sensor Calibrator, Model 1260-XX

or Model 1200-26 or permeation tube

- Calibration Gas

- Disbursing Calibration Adapter (Model 5358-

01)

5.4 Calibration Procedure

Routine calibrations are easily performed using the

magnetic tool provided with each sensor.

Briefly hold the magnet tool close to the small dot

located on the lower edge of the front panel. The

arrow on the upper left side of the LED will illuminate

and the 4-20 mA output is locked at 1.5 mA, indicating

that the sensor module is ready for calibration. Sim-

ply expose the sensor to a ZERO gas and observe the

L.C.D. readout. In normal situations, simply exposing

the sensor to an atmosphere free of the gas of interest

is satisfactory. If it does not return to the correct

ZERO reading, a ZERO adjustment is required. Hold

the magnet close to the UP ZERO or DOWN ZERO

indicators and adjust the reading to the correct ZERO

reading.

Connect the calibration adapter and expose the sen-

sor to an appropriate SPAN gas using a span mixture

containing a known concentration of the gas of inter-

est at a minimum flow rate of 300 cc/minute. (Use per-

meation tube for 4105-25) Allow 3-5 minutes before

making any adjustments.

If the L.C.D. does not display the correct SPAN value,

a SPAN adjustment is required. With the arrow still

flashing, hold the magnet close to the UP SPAN or

DOWN-SPAN indicators and adjust the reading to the

correct SPAN value. (The 4-20 mA out is automati-

cally adjusted.)

The monitor is now calibrated. Deactivate calibration

by holding the magnet close to the small dot again.

This releases the 1.5 mA lock.

5.5 Fault Identification

A Fault condition is detected if the sensor output drifts

far enough negative to cause the 4-20 mA output to

reach 1.5 mA (±15% of full scale) or the sensor failure.

The sensor module demonstrates that a fault condi-

tion exists by illuminating the RED LED on the front

panel and by holding the 4-20 mA output at 0 mA.

These conditions will exist until the fault is corrected.

Table 4.1

Calibration Span Gas Flow Rates