For Machines Mfg. Since 8/09 Model SB1018

-29-

OPERATION

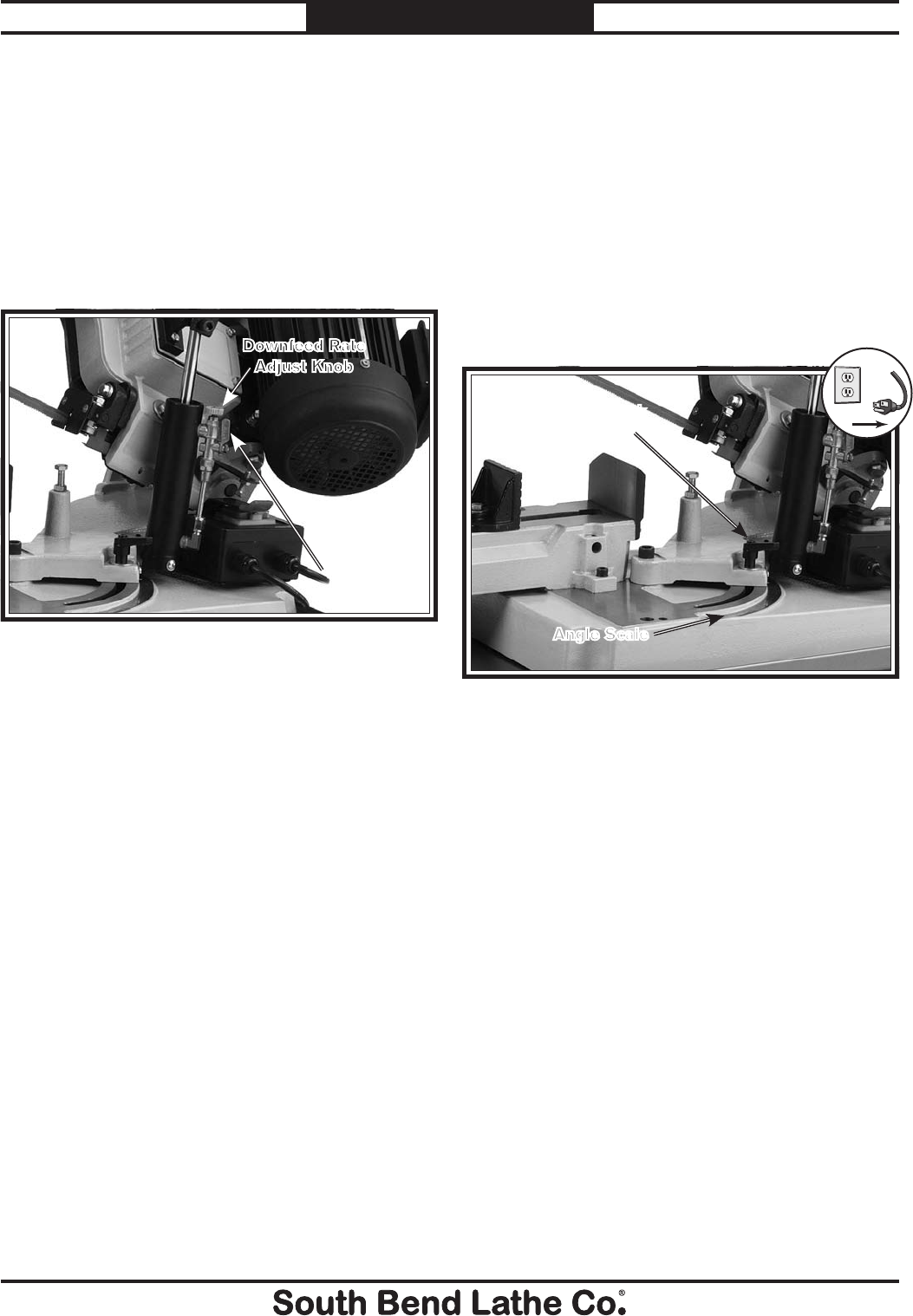

The downfeed valve starts and stops headstock

downfeed.

The downfeed rate is adjusted by turning the

downfeed rate adjust knob (Figure 37). Turning

the knob clockwise decreases the downfeed rate

and turning the knob counterclockwise increases

the downfeed rate.

Downfeed Rate

Figure 37. Downfeed rate controls.

Downfeed Rate

Adjust Knob

Downfeed

Valve

During operation, pay attention to the chips

being produced from the cut and compare them

to the Chip Inspection Chart on Page 28 to

properly set the downfeed rate.

Angle Cuts

The headstock can be swiveled to cut angles

0°–45° to the right and 0°–60° to the left for a

total swing of 105°

Cuts to the Right

1. DISCONNECT BANDSAW FROM POWER!

2. Loosen the lock handle shown in Figure

38, then swivel the headstock to the desired

angle, using the angle scale as a guide.

Figure 38. Swivel base.

Swivel Lock

Handle

Angle Scale

!

3. Move the saw through its full range of

motion to make sure the blade will not

contact the vise during operation, then

tighten the swivel lock handle.